JVC TM-R14U User manual

Other JVC Monitor manuals

JVC

JVC GM-H40L2A Quick start guide

JVC

JVC LT-50NQ7115A User manual

JVC

JVC TM-1400U(CV) User manual

JVC

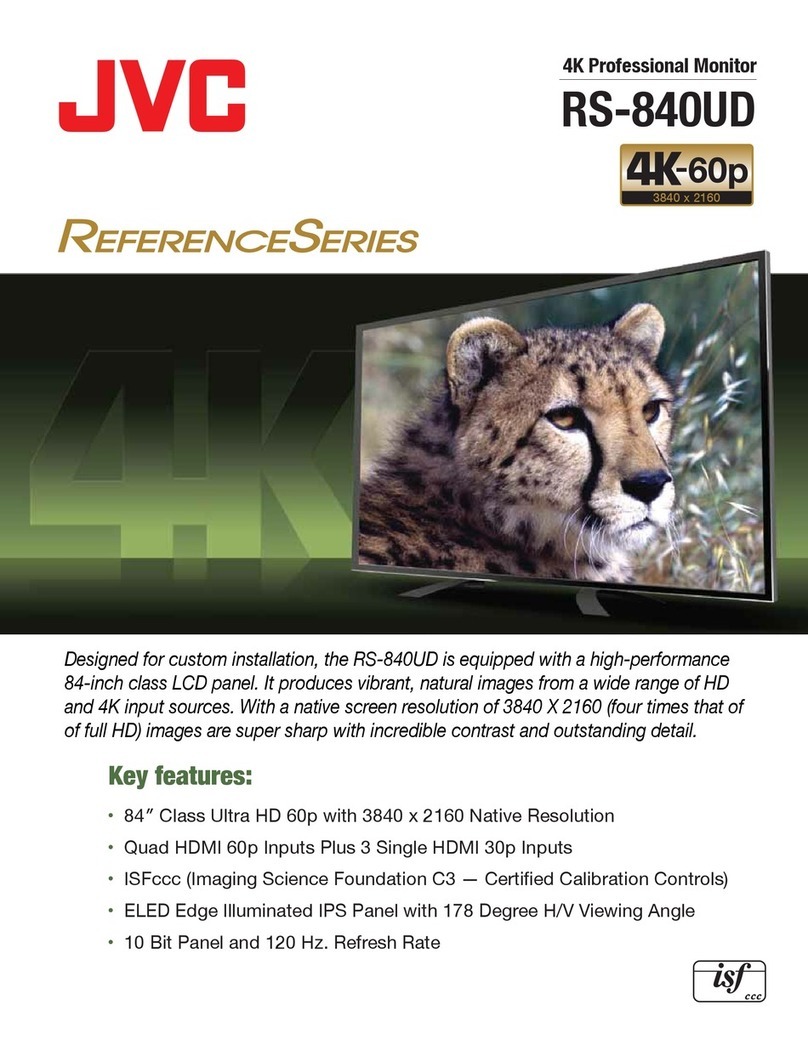

JVC RS-840UD User manual

JVC

JVC GD-V4210PZW - High Contrast Plasma Display User manual

JVC

JVC GM-P421U User manual

JVC

JVC TM-A101GU - Multi-purpose Color Monitor User manual

JVC

JVC DT-V20L3DY - VȲitǠSeries Studio... User manual

JVC

JVC TM-1500PS User manual

JVC

JVC KW-M560BT User manual