2

For USA and CANADA

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION : TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK).

NO USER SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of impor-

tant operating and maintenance (servicing) instruc-

tions in the literature accompanying the appliance.

The lightning flash with arrowhead symbol, within an

equilateral triangle is intended to alert the user to the

presence of uninsulated “dangerous voltage”within the

product's enclosure that may be of sufficient magni-

tude to constitute a risk of electric shock to persons.

Information for USA

This device complies with Part 15 of the FCC Rules.

Changes or modifications not approved by JVC could void

the user's authority to operate the equipment.

WARNING:

TO REDUCE THE RISK OF FIRE OR

ELECTRIC SHOCK, DO NOT EXPOSE THIS

APPLIANCE TO RAIN OR MOISTURE.

AVERTISSEMENT:

POUR EVITER LES RISQUES D'INCENDIE OU

D'ELECTROCUTION, NE PAS EXPOSER

L'APPAREIL A L'HUMIDITE OU A LA PLUIE.

FEATURES ........................................................................... 2

OPERATING PRECAUTIONS ............................................... 3

SAFETY PRECAUTIONS ..................................................... 3

CONTROLS, CONNECTORS AND INDICATORS ................ 4

INSTALLATION ..................................................................... 5

CONNECTIONS .................................................................... 8

HOW TO USE THE FERRITE CORE.................................... 9

TROUBLESHOOTING ........................................................ 10

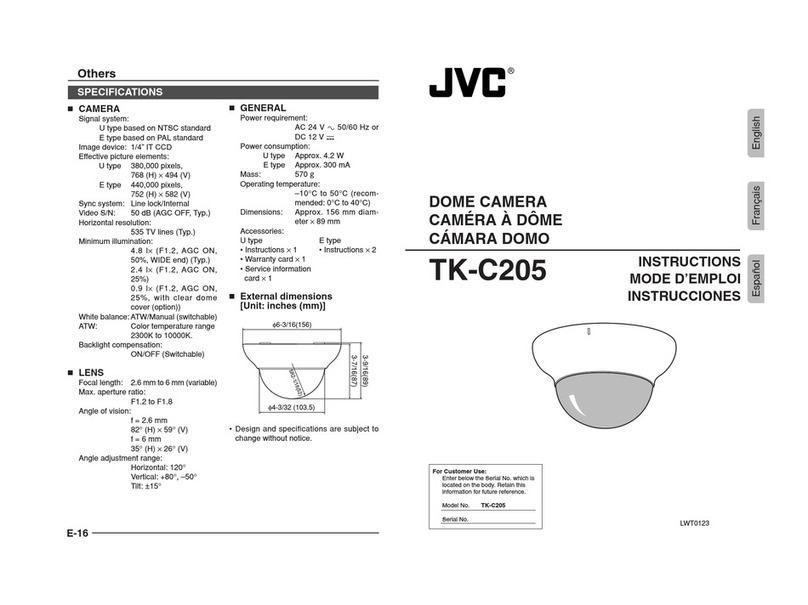

SPECIFICATIONS ............................................................... 11

Due to design modifications, data given in this instruction

book are subject to possible change without prior notice.

CAUTION

INFORMATION (FOR CANADA)

RENSEIGNEMENT (POUR CANADA)

Cet appareil numénque de la classe [B] respecte toutes les

exigences du Réglement sur le matériel brouilleur du Canada.

This Class [B] digital apparatus meets all requirements of

the canadian Interference-Causing Equipment Regulations.

FEATURES

䡵Features large aperture lens with 16x zoom ratio (f=4.5 to

72mm, F1.2, at wide angle).

䡵Wide coverage angle (Horizontal 3.8°to 56°, Vertical 2.9°to

44°).

䡵64 preset positions.

䡵360 degree endless panning.

䡵Maximum 240 degree/sec. panning speed.

䡵Maximum 2-second zoom speed.

䡵One-push auto focus capability.

䡵RS-485 (Maximum Number of Connections: 32) or RS-422A

control signal.

䡵High-quality pictures by adopting dome cover with optical

distortion compensation and CCD with 380,000 (U: type)

or 440,000 (E: type) effective pixels.

䡵Adopts large aperture lens, highly sensitive CCD.

(Minimum illumination : 2.8 lx, at wide angle)

䡵Auto panning function.

䡵Variable panning speed.

The panning speed is varied automatically according to

the zoom ratio of the lens. (The panning speed decreases

when the zoom lens is set near TELE and increases when

it is set near WIDE.)

䡵Auto flip

When the camera reaches its tilting limit, it automatically

flips itself over by 180 degrees by panning around.

(This makes it possible for the camera to continue tilting

even after it has been tilted straight downward.)

䡵Auto patrol

Preset positions are activated in sequence.

䡵Menu screen display

A built-in character generator provides an on-screen menu

display for easy selection and setting of various functions.

䡵5-language on-screen display

Names or designations for camera, preset, area and alarm

can be displayed in English, German, French, Italian and

Spanish. (E type only)

䡵Area title indication

The 360˚panning angle (horizontal rotation) is divided into

16 sectors, allowing you to check the title in each area.

When the camera is manually panned, the preset area

designation is shown on the screen.

CONTENTS

Thank you for purchasing this product.

Caution during continuous use

Continuous use of the preset sequence or auto panning op-

eration may make the service life much shorter than expect-

ed.

The guaranteed operation count for the zoom lens of this

camera is around 400,000 times.

(Example)

24 hours of operation per day with single zoom

operation per minute:

400,000 (times)/60 (minutes)/24 (hours) = 278 (days)

䡵Before starting an important recording, be sure to per-

form a test recording in order to confirm that a normal

recording is possible.

䡵We do not accept liability for the loss of a recording in

the case of it becoming impossible to record due to a

problem in the video camera, VCR or video tape.

䡵We do not accept liability for any damage to the camera

in cases when it is dropped because of incomplete in-

stallation due to not observing the installation instruc-

tions correctly. Please be careful when installing the

camera.

3

Operating precautions

●To save energy, when it is not being used turn the system's

power off.

●This camera has been designed for indoor use. It cannot be

used outdoors.

●This camera has been designed exclusively to be hung from

the ceiling.It may malfunction if it is placed on a surface or if

it is tilted.

●Do not install or use the camera in the following places.

•In a place exposed to rain or moisture.

•In a place with vapor or oil soot, for example in a kitchen.

•In a temperature outside the operating temperature range

(-10°C to 50°C).

•Near a source of radiation, X-rays, strong radio waves or

magnetism.

•In a place subject to vibration.

•In a place with excessive dirt.

●Insufficient head ventilation of the camera may cause a mal-

function.

Be careful not to block the ventilation to the camera.

●If this camera and the cables connected to this camera are

used where there are strong electromagnetic waves or where

there is magnetism present, for example near a radio or TV

transmitter, power transformer or an electric motor, the pic-

ture may produce noise and the colors may be affected.

●This camera incorporates an AGC circuit. As a result, when

it is used under low light conditions, the camera sensitivity

is automatically boosted and the picture may look uneven.

This is not a malfunction however.

●When the AGC is ON in the auto iris mode, varying the iris

with the IRIS control button may not change the picture

brightness due to the gain boost function. In this case, switch

the AGC OFF or set the iris mode to manual.

●In auto iris mode, the IRIS control buttons may not function

under certain brightness conditions (i.e. when a sufficient

amount of light cannot be obtained). In this case, set the iris

mode to manual.

●The white balance setting when used under a fluorescent

lamp should be ATW (Auto White).If it is set to MANU (Man-

ual), the white balance may not be adjustable.

●When presetting this unit’s position, turn it on and wait until

it has warmed up sufficiently inside (about 30 minutes). This

is to avoid a change in the lens focus due to a rise in

temperature after installation.

●When this camera is used in the AUTO white balance mode,

the recorded colors may be slightly different from the actual

colors due to the operational principles of the auto-tracking

white balance circuit. This is however not a malfunction.

●If a high-intensity object (such as a lamp) is shot, the image

on the screen may have vertical lines (smear) or blur (bloom-

ing) at its periphery. This is a characteristic of the CCD, and

is not a defect.

●The electronic shutter of this camera has been set to 1/60(1/

50) sec. at the factory. When the camera is used under a

fluorescent lamp or in an area with a local power frequency

of 50/60 Hz, change the shutter speed to 1/100(1/60) on the

remote control unit. (The sensitivity deteriorates slightly with

a shutter speed of less than 1/100(1/60) sec.)

Utype (Etype)

●When the camera is used to monitor the same position con-

tinuously for 24 hours or more, the contact resistance of the

horizontal rotary parts may increase after long hours of use,

and the picture may be affected by noise interference or the

remote control operation may become unstable.

To prevent this, turn the system power off and on at least

once a week (to initialize) and also clean the contacts.

●Do not touch the dome cover of the lens directly with your

hand, contamination of this cover will lead to a deterioration

of the picture quality.

●Observe the following when carrying out camera mainte-

nance.

•Turn the power OFF before proceeding to carry out main-

tenance.

•Clean the dome cover lens using a lens wiper cloth (or a

tissue).

If it is contaminated seriously, clean the contaminated part

with a cloth (or a tissue) which has been soaked in a solu-

tion of water and a neutral detergent.

●In order to reduce the generation of unnecessary signals,

be sure to install the provided ferrite cores when connect-

ing the cables. (See “How to use the ferrite core”on page 9)

●Some subjects may not be brought into focus with the auto-

focus facility of this unit. Focusing will be made easier by

locating a subject with highly contrasted vertical stripes near

the center of the image.

●Optional controller is required to use the TK-C675B camera.

Please contact your local dealer or installer for more infor-

mation about this controller.

Safety precautions

•As this unit contains parts which rotate at high speeds, it

should be installed in a place suitable to withstand the pos-

sible vibrations and to support the unit weight of 2 kg. If the

ceiling is made of dressed-face plywood, plaster board or

another material which is not strong enough to support the

unit, reinforce the installed surface by using a reinforcing

material (including plywood). If the reinforcement is insuffi-

cient, the monitor picture may be blurred due to vibrations

or in the worst case the unit may fall.

•Installation of this unit requires expertise. Please contact

your dealer for details.

•The ceiling to mount the TK-C675B has to be strong enough

to support ten times the weight of this product.

If the ceiling is not strong enough, make sure to apply rein-

forcement to the ceiling before installation.

•Be sure to tighten the screws and nuts securely, Insufficient

tightening may cause the unit to fall from its mount.

•The unit is to be powered by an AC24V.

Isolated power supply only. (E type)

Class 2 only (U type)