6

TRADITIONELLE DEUTSCHE QUALITAT

· ·

OPERATING THE CULTIVATOR ON THE MOUNTAINOUS TERRAIN

1. Follow the correct positioning of the device on the slopes. The slope angle of

10% corresponds to a 10 cm lift per 100 cm horizontal plane. Never attempt to

plow soil on steeper slopes in order not to lose control of the device.

2.When operating the device on slopes or mountainous terrain, be sure to install

all the mills.

3. A person operating the cultivator must not stand below the device in order not

to end up under the working cultivator if they lose control of it.

4. Do not operate the device across a slope. Only move forward, do not jerk the

cultivator back and forth.

5. Be careful when changing the direction of the cultivator.

6. Slow down when on stony ground.

7. The cultivator should only be operated at the pace of a step since faster

movement poses a tripping and slipping hazard, etc.

8. To adjust the running depth of the device, apply greater or lower pressure to

the coulter handle.

9. Do not turn over the engine and do not change its main position!

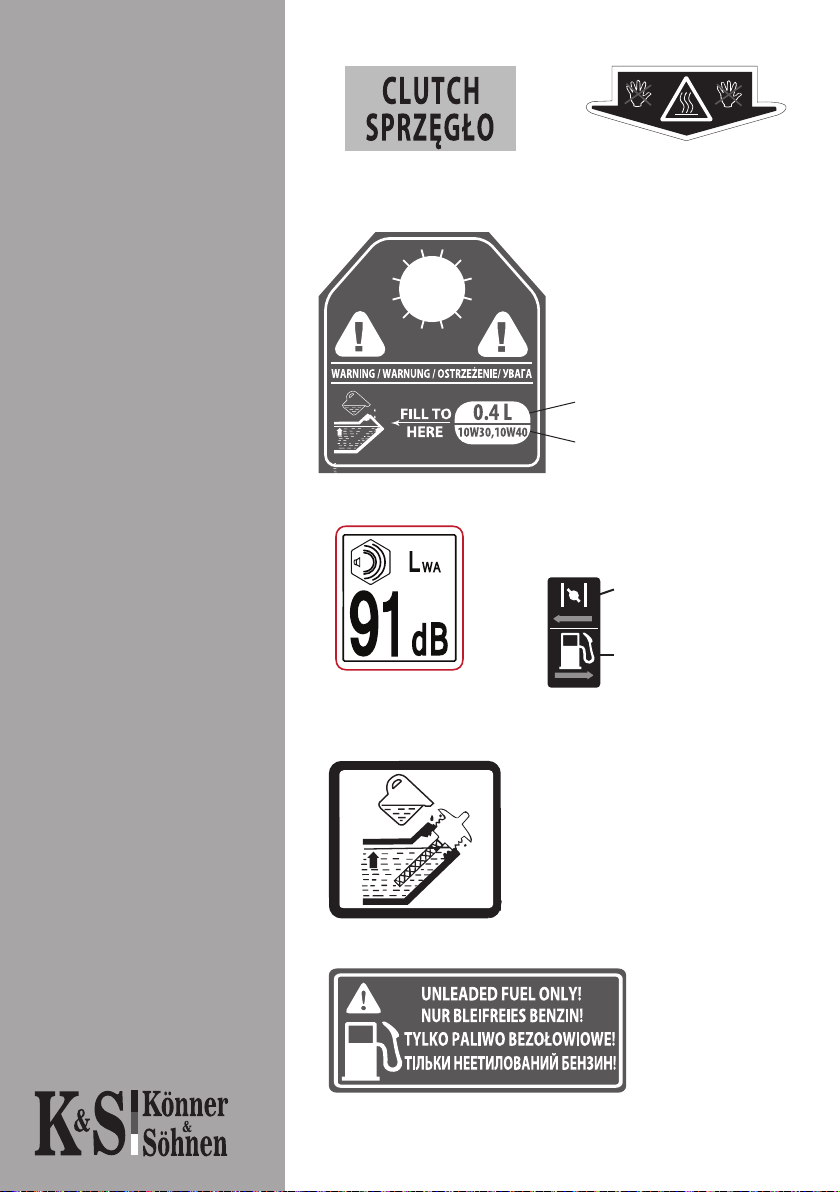

GASOLINE USE AND STORAGE

Gasoline is an extremely toxic and ammable substance. Therefore, be sure to

observe the following rules for its storage and use:

1. Only store fuel in hermetically sealed containers specially designed for this

purpose. Keep the gasoline container in a cool, dark place away from sparks and

open ames.

2.When the engine is running, the cultivator emits exhaust gases that can cause

poisoning. Do not use the device in closed, poorly ventilated areas.

3. Refuel the cultivator outdoors before starting the engine. Do not open the fuel

cap and add gasoline if the cultivator is still hot after work.

4. Ensure there is enough air space to allow for fuel expansion. Fill the fuel tank

to approx. 4 cm below the lower edge of the tank ller neck. Do not ll the tank

completely.

5. Carefully remove any spilled gasoline from the cultivator surface. Never start

the engine until the gasoline vapors have evaporated and the surface is clean.

6. Always close the fuel cap tightly.

7. To empty the fuel tank completely, start the cultivator engine outdoors until

the fuel is fully burnt.

8. Only transport the cultivator when the fuel tank is empty and the fuel valve

is closed.

9. Allow the device to cool down before placing it in storage.

10. For safety reasons, do not leave the device indoors with gasoline in the fuel

tank. Gasoline vapors can come into contact with sparks or open ames, which

can cause vapors to ignite.

11. Check the device for damage and leaks in the fuel line, fuel tank and fuel cap,

as well as for damage to the damper and protective plates on a regular basis.

Replace parts, if necessary, in a timely manner.