Maintenance instructions according to EN 1176-1

2019 Kaiser & Kühne Freizeitgeräte GmbH 2019-09-10

Im Südloh 5 – D27324 Eystrup – Telefon 0 42 54/93 15-0 – Fax 0 42 54/93 15 24 – E-Mail info@kaiser-kuehne-play.com

-M A I N T E N A N C E I N S T R U C T I O N S- Single point swing Item 040710004 Page 2 of 10

Instructions for the professional inspection and maintenance of single point swings

oPlayground equipment is subject to a wide range of stresses and strains over the course of its

useful life, which can reduce or even eliminate the original safety. Regular inspection and

maintenance ensures that the required safety of playground equipment is maintained.

oThis maintenance manual contains all the instructions needed to perform the inspection tasks

and to comply with the inspection periods. It is assumed in this maintenance manual that the

playground equipment is installed in a normally frequented playground in normal surroundings. If

there are local factors that deviate from the normal, the inspection periods must be adjusted. This

may cause the time intervals specified by the manufacturer / distributor to be shortened. An ex-

tension of the time intervals is excluded as these are minimum requirements.

oAmong the local factors that require shortening of the inspection periods are, for example, loca-

tions with heavy use, e.g. schoolyards, kindergartens, amusement parks; location with high levels

of vandalism; locations near the coast; locations with air pollution; playground equipment increas-

ing age.

oFurthermore, this maintenance manual assumes that the described inspections and maintenance

work will be carried out by personnel with suitable qualifications. Certain tasks (such as welding)

can only be performed by qualified professionals or require machining by the manufacturer / dis-

tributor.

oThe owner / operator of the playground should set up a suitable inspection plan for the play-

ground and document the inspections and maintenance performed there for the particular play-

ground equipment.

One-time maintenance work

Four weeks after installation, all screw connections must be checked and tightened if necessary. In this

case, the specified advice in the regular maintenance work e. g. to turning moments has to be observed.

Regular maintenance

1. Routine visual inspection

1.1. 1x weekly (or different, determined by local factors)

Check the minimum space of the playground equipment for cleanliness.

Check playground equipment for consequences of vandalism, e. g. missing or damaged

components.

Check playground equipment for the effects of weather conditions, eg. B. by storm or frost

2. Operational inspection

2.1. 1x monthly (or different, determined by local factors)

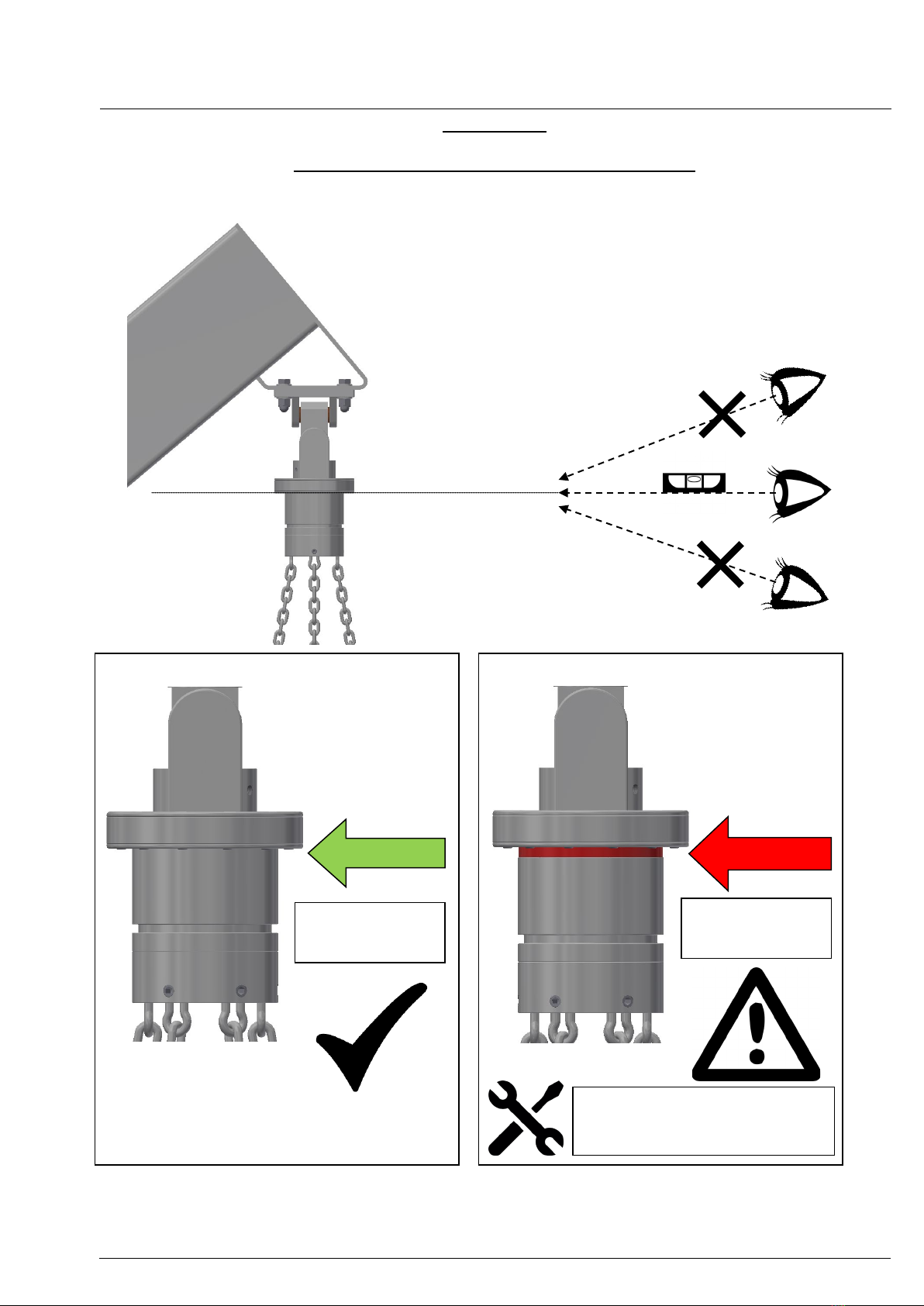

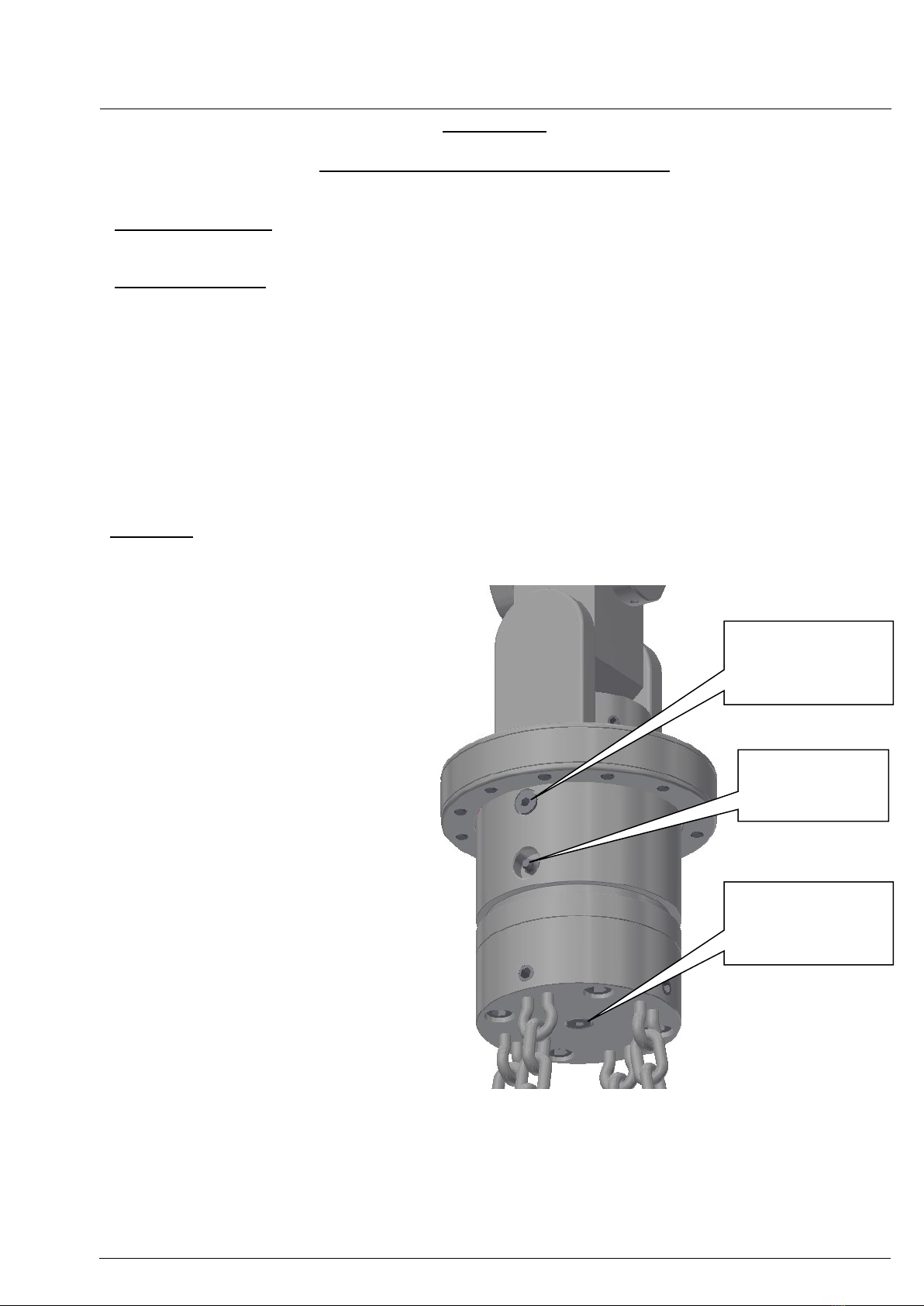

Check for visibility of the warning groove (red-colored ring on the swivel housing). If the

ring is visible in a horizontal direction, there is a need for repair. See appendix "A1 Visual in-

spection of swivel at least once a month"

Testing for smoothness of running. Relieve the swing platform and the universal joint from

load. To check the swivel is slowly put into rotation by hand. If the swivel rotates without an-

gular offset (well visible on the swing chains), it is fine and smooth of running.

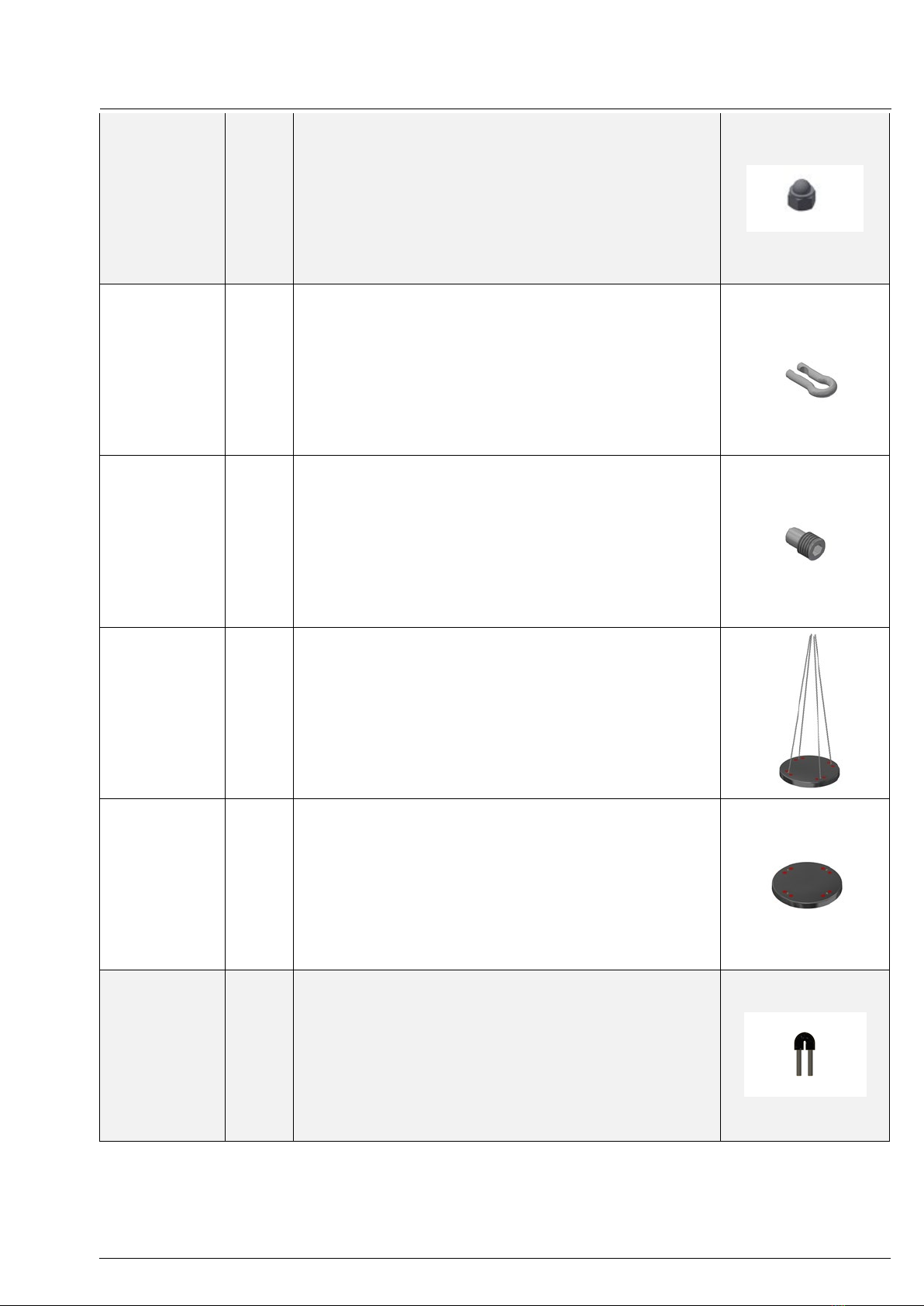

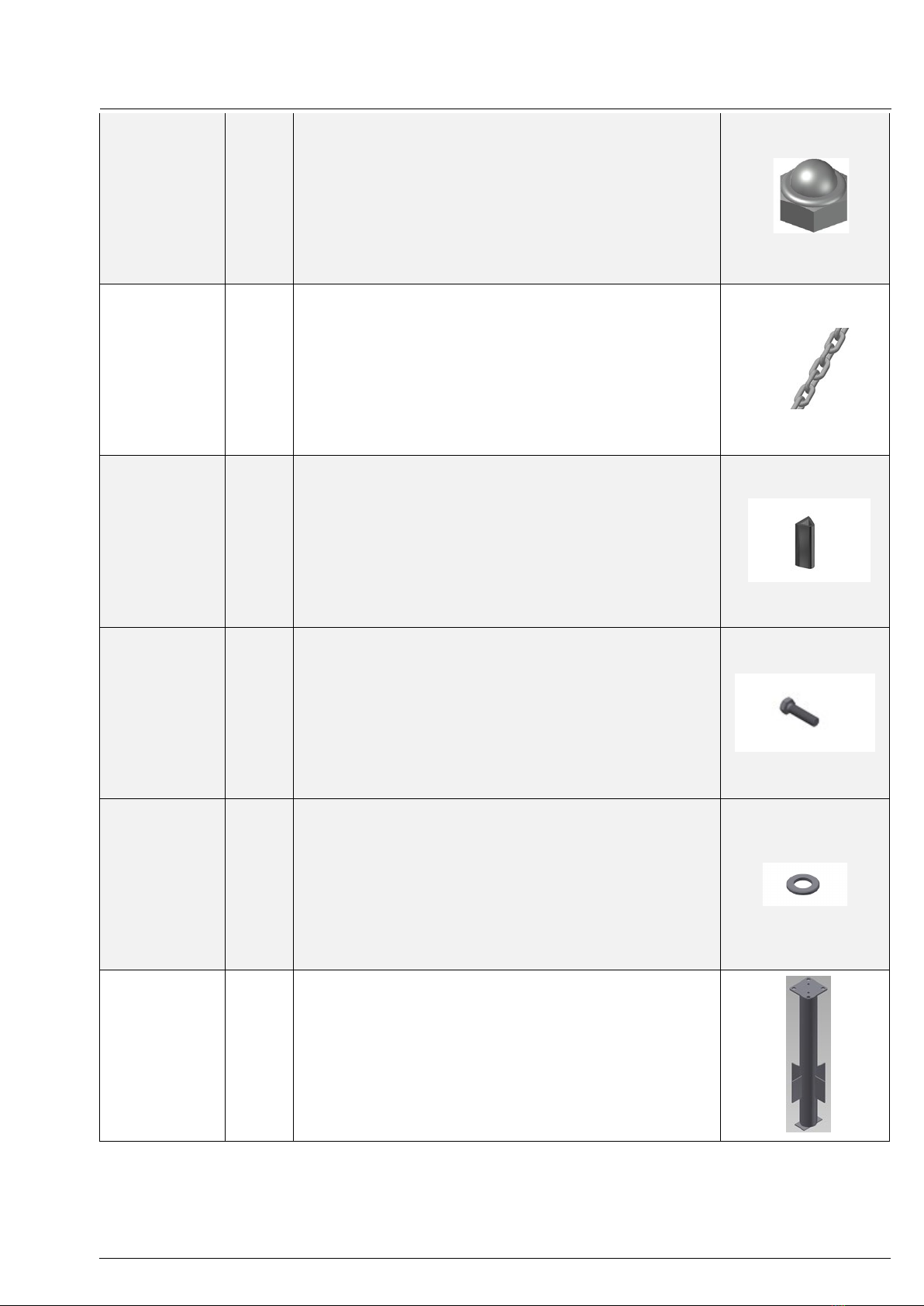

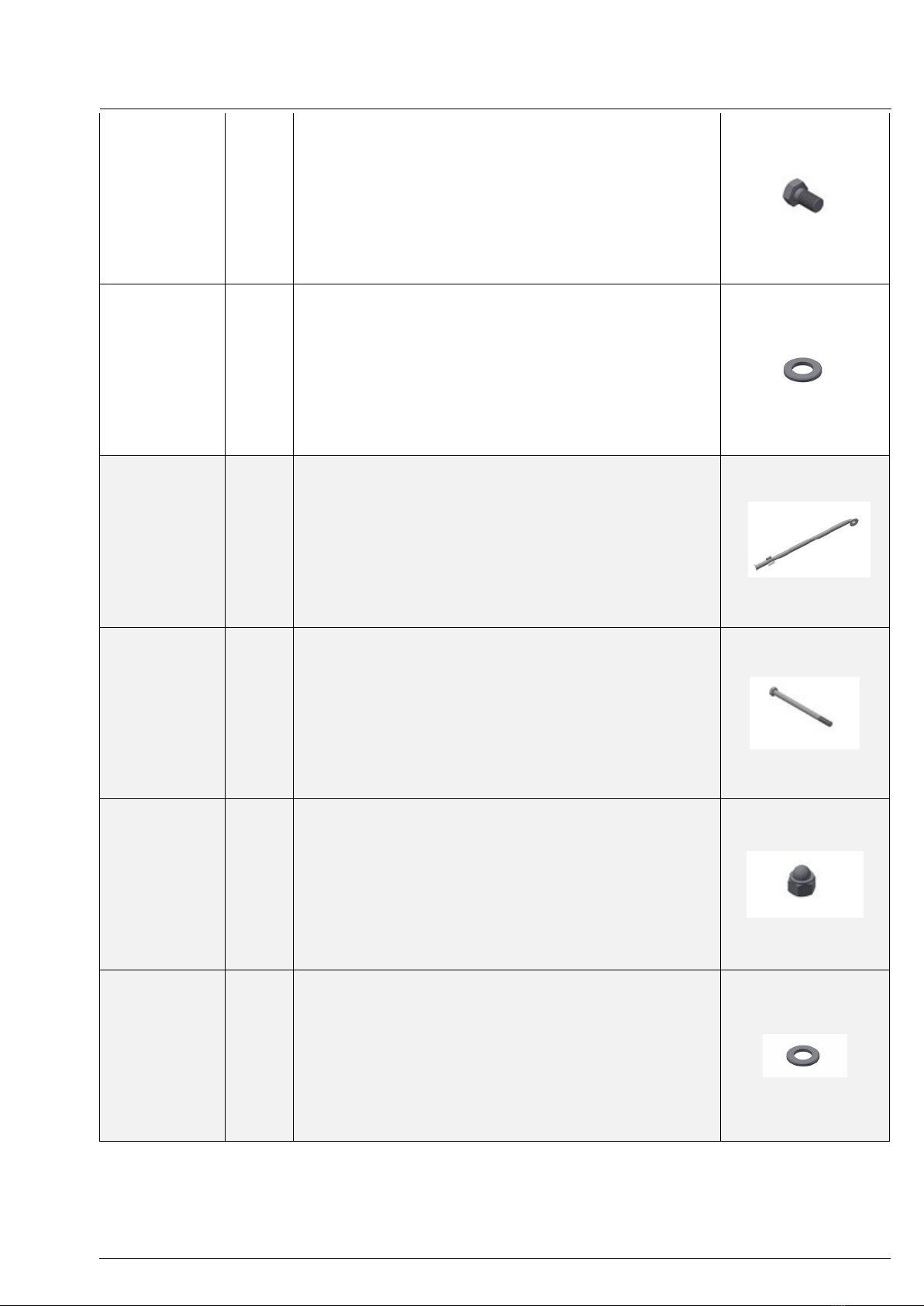

Check swing chains and connecting elements for wear, replace if necessary. Please note

that the cylinder screws in the chain adapters are fastened hand-tight with a long Allen key or

a ratchet with a socket wrench, without over-tightening the hexagon socket.

Check plastic parts such as protective edges, linings, sheathing, sleeves, etc. for loss,

signs of wear and damaged areas and replace if necessary.