Operation Manual TR-50

KAKA Industrial®

— 3 —

5. Be alert and think clearly. Never operate

tools when tired, intoxicated or when taking

medications that cause drowsiness.

6. Keep work area clean. Cluttered work areas

invite accidents.

7. Work area should be properly lit.

8. Keep visitors at a safe distance from work

area.

9. Keep children out of workplace. Make

workshop childproof. Use padlocks to prevent

any unintentional use of tools.

10.

Assemble only according to these

instructions.

Improper assembly can create

hazards.

11.When tools are not in use, store them in a

dry, secure place out of the reach of children.

Inspect the tools prior to storage and before

reuse.

12. Maintain product labels and nameplates.

These carry important safety information.

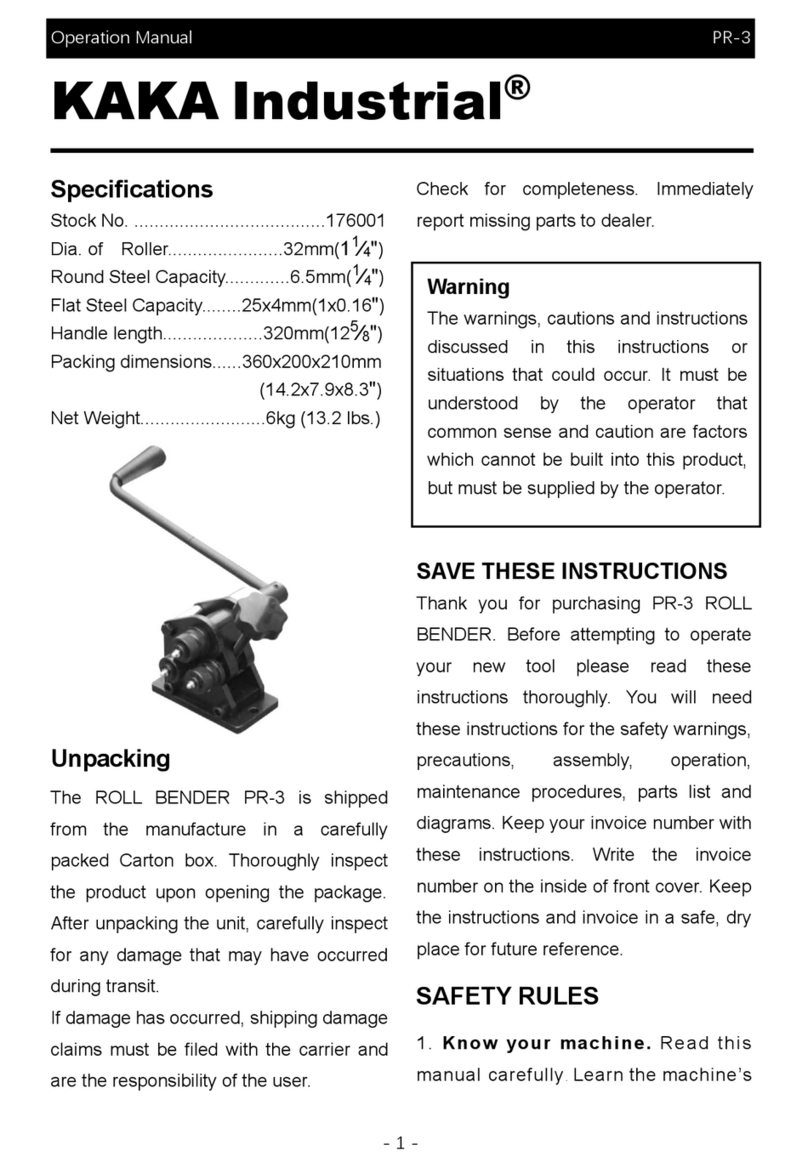

Assembly

The Tube Roller must be securely mounted

to a solid surface before using, the size of the

mounting hole is 11 mm.

Operating the tool for certain operations will

require exerting considerable force on the

handle, thus it is essential that the tool be

mounted to a heavy or immovable work bench

or other work surface. Be certain there will

be adequate clearance for the entire range of

motion of thehandle with no potential pinch

points for the operator’s hands.

WARNING

Before drilling the mounting holes, make

sure that there is no electrical conduit or

water pipes.

Operation

1. The chain can be tightened or loosened by

adjusting the screw #31.

2. Loosening handle #7 to adjust the height of

stand.

3. When the roller need to be changed, please

screw off #11, #9, take off the cotter pin #37,

and washer #36, and remove the back frame

#12, then the lower roller #16 can be changed;

the upper roller #38 can be changed by taking

off pin#39.

4. Turning Screw Rod #43 to adjust feeding

amount according to different wall thickness of

tube. Thinner tube and less feeding amount,

or else the tube section will be deformed.

5. The bearing should be lubricated frequently

to increase it’s life length.

CAUTION

The Center distance of two Lower rollers

can be adjusted as required.

WARNING

Do not roll a stock thicker than the roller's

capacity.

You will damage the bender.Measure

the thickness before use.

Maintenance

1. Maintain your tools. It is recommended

that the general condition of any tool be

examined before it is used. Keep your tools

in good condition by adopting a program

of conscientious repair and maintenance

in accordance with the recommended

procedures found in this manual.

2. Keep tool clean for safest operation. Only

use soap and a damp cloth to clean your tools.