INSTALLATION GUIDE

KALE FANS

www.kalefans.net

2019

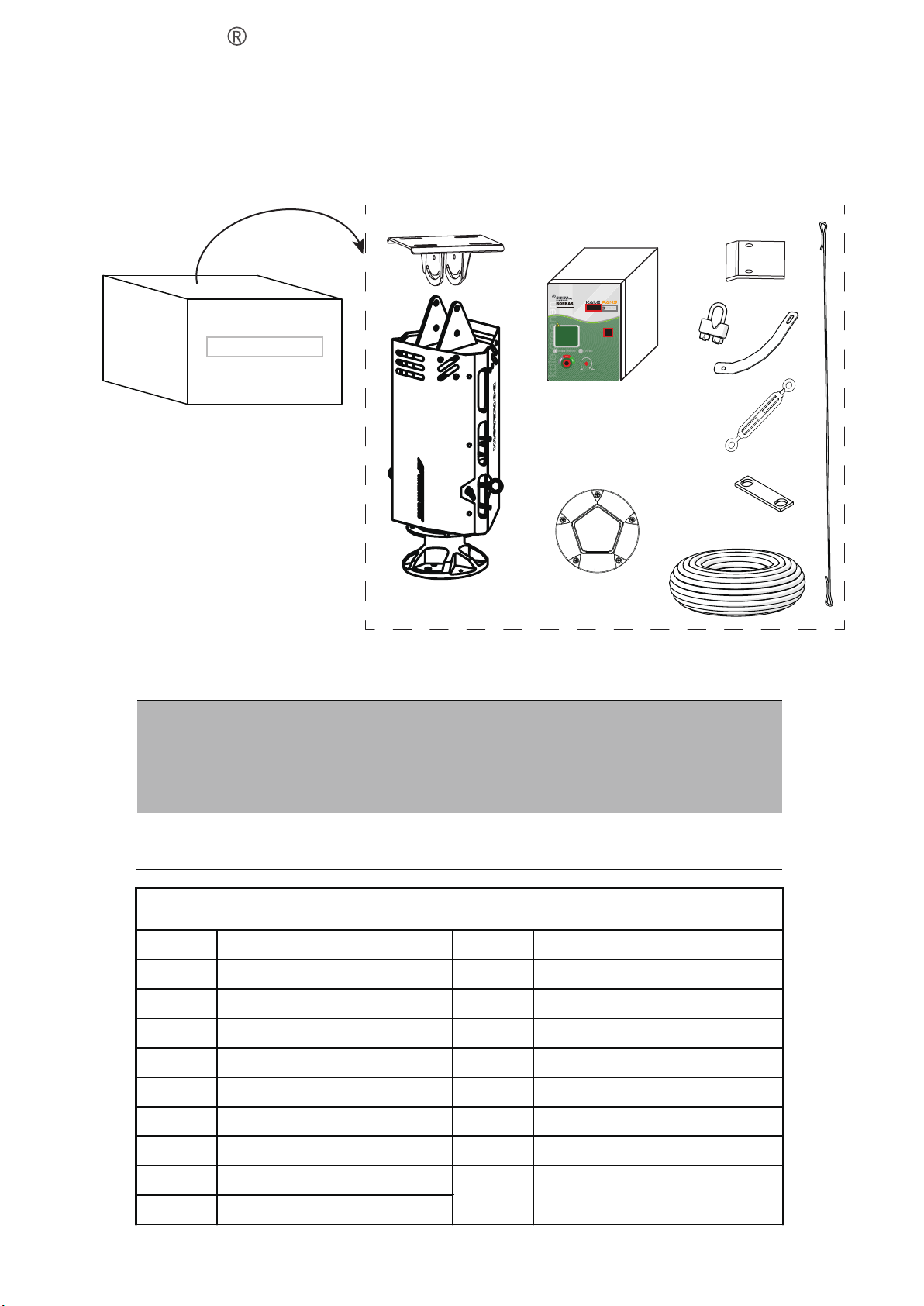

BOREAS series

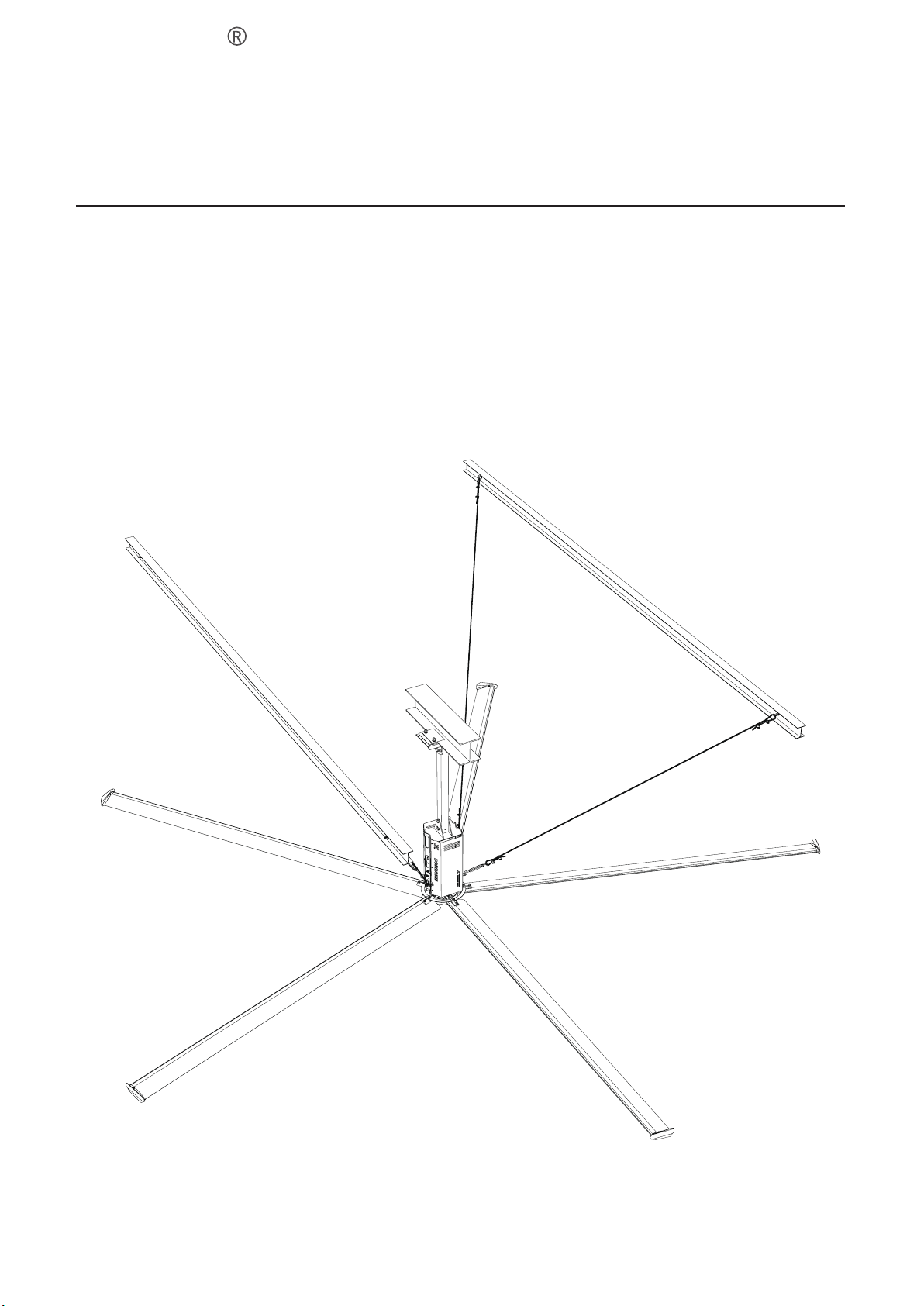

BOREAS series Big Energy-Saving fan is a super fan with a diameter of 7.3m! Kale Airfoil Blades, which are streamlined,

are developed with the advanced technologies and the principle of aerodynamics. With a power of 1.5KW or less, the

blade is able to drive a mass of air and makes the natural wind system with ultra-large area, which leads to the double

function of ventilation and temperature reduction. Compared to the traditional HVAC conditioner and small high-speed

air blower, the fan is superior in application, and that makes it immaculate for the large space to ventilate and reduce

temperature. BOREAS Series fan is a primary product for KALEFANS and its coverage can be up to 1600 sq metres. The

fans are mainly applied in large space such as the plant, logistics & warehouse, supermarket and farm, etc.

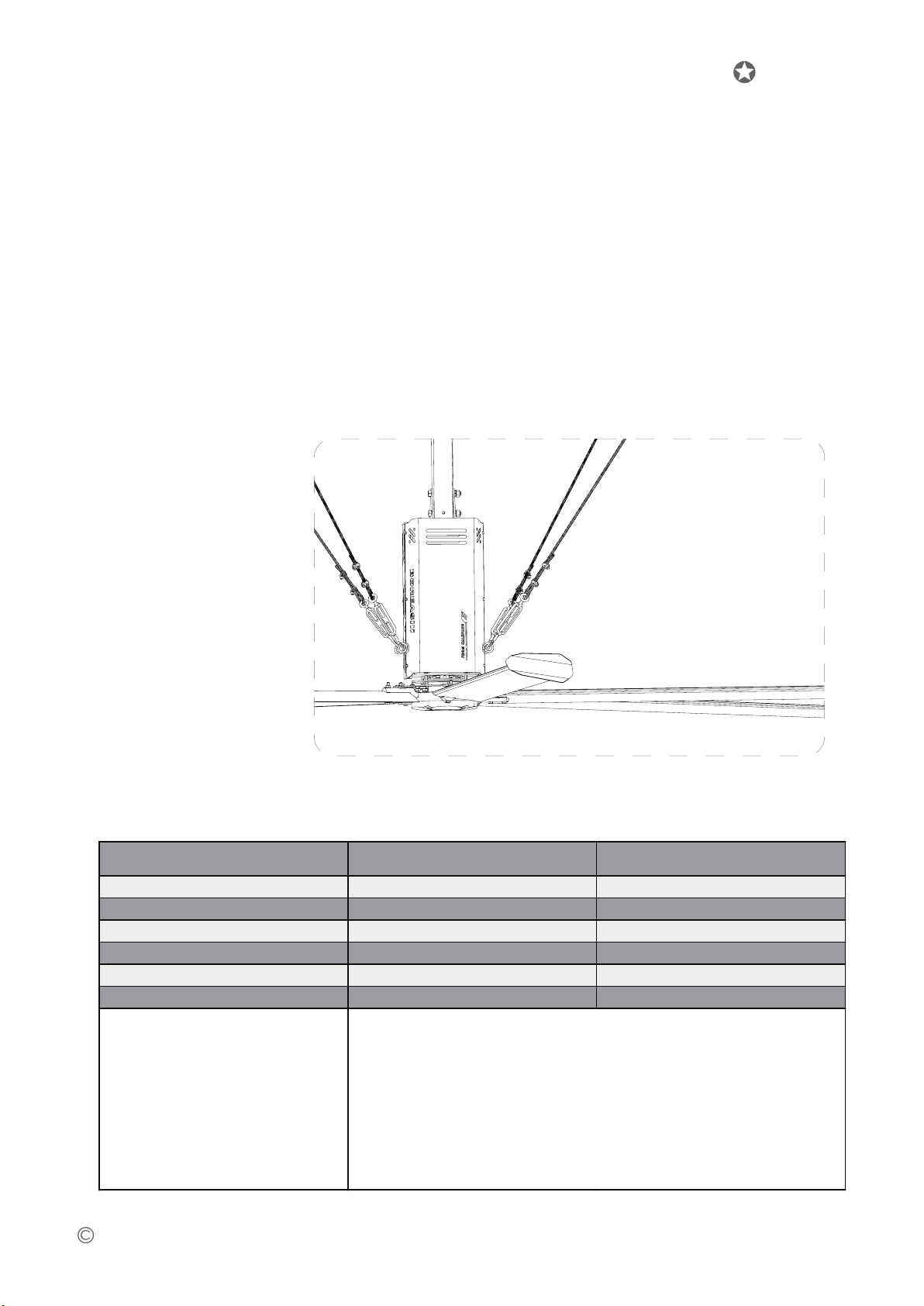

1.1 Product specification table

-3-

1. Production series introduction

技术规格 Technical Specifications 20ft(6.1m)24ft(7.3m)

型号Model D4BAA61 D4BAA73

满载风量 Air disp.@Max speed

12000m³/min 13050m³/min

最大转速 Maximum speed 70RPM 60RPM

风扇主体重量 Fan weight 97kg 110kg

电机功率 Moto size 1.5Kw 1.5Kw

满载电流 Full load amps 3.5Amps/380V 5.7Amps/220V 3.5Amps/380V 5.7Amps/220V

1、重量计算:产品重量不包含控制箱,

顶部连接构件等。

2、尺寸:以上所列产品尺寸为标准品,

其他规格尺寸可定制。

3、噪音:声级计距离电机1m,电磁噪音

40dB(A)以下。

4、包装:标准木箱包装。

5、输入电源:三相380V/220V,单相

220V可选。

1, Weight: the weight does'nt contain control box, top connection parts

etc.

2, Size: the above-mentioned product size is standard, other size can be

customized.

3, Noise: sound level measured a distance of 1 m from the motor,

electromagnetic noise is less than 40 db(A).

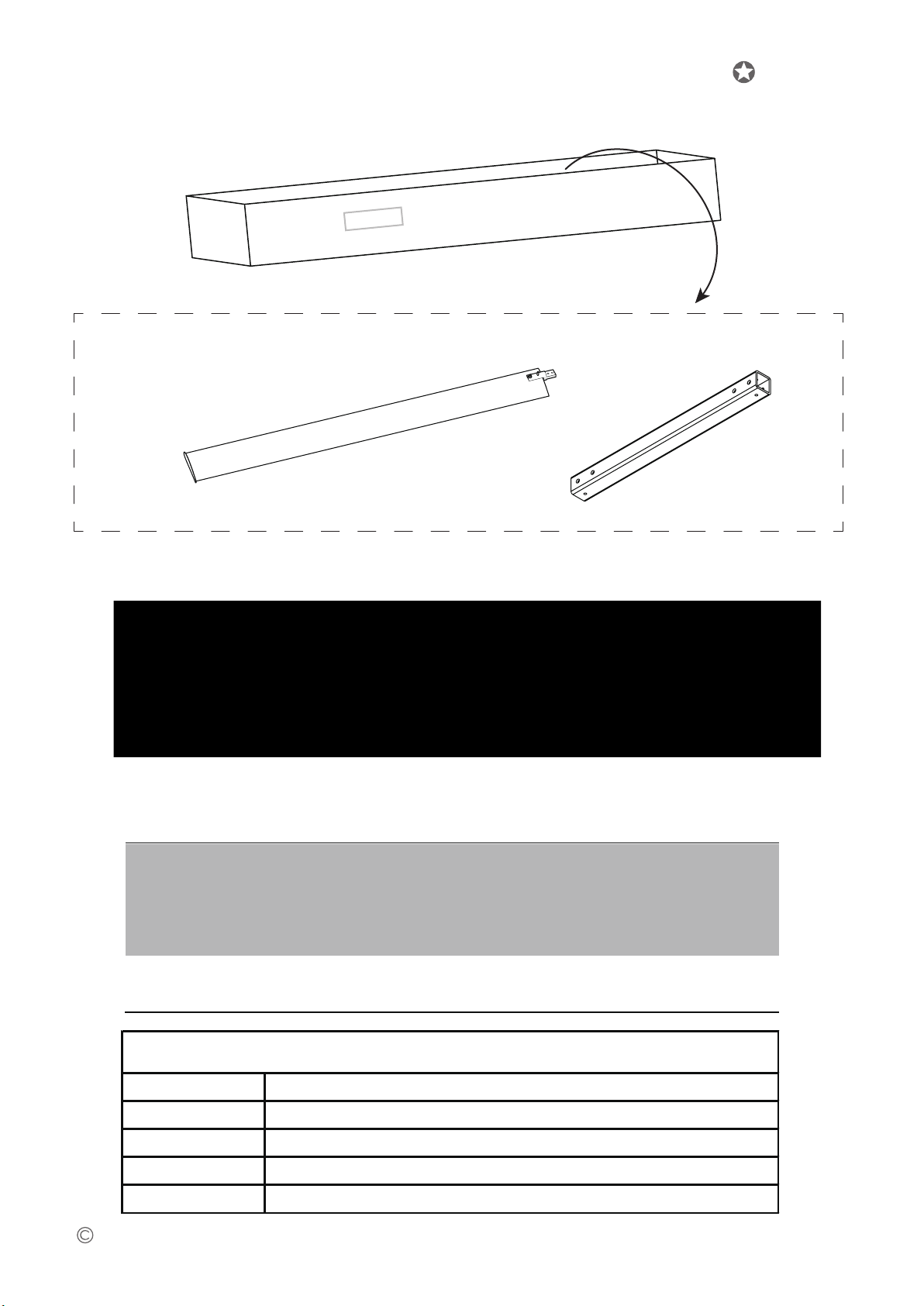

4, Packing: Export standard crates.

5, Input power: 380 VAC, 3P, 50/60 Hz.220 VAC, 3P, 50/60 Hz.220 VAC, 1P,

50/60 Hz.