OWDMANUAL 1114 KAM CONTROLS, INC.

3

INTRODUCTION CONTINUED

Rugged,easytouseandextremelyaccurate,theKAM®OWD®OilWaterDetectoristheidealinstrumentforcontinu-

ouslymonitoringwaterconcentrationinyourpipeline.ItisdesignedinaccordancewithAPI,ASTM,ISO,EI,UL,and

DINstandardsamongstothers.Especiallyvitalinproductionmanagement,theOWD®sensor lets you maximize oil

productionversusproducedwater.ThesimplicityofdesignandqualityofengineeringemployedintheOWD®sensor

meantherearenomovingparts.Patentedmicrowavesensorsmeasuretheconductivity,dielectric,andboththereal

andimaginarypartofpermittivityoftheuidwithanextremelyhighdegreeofaccuracy,andmeasurementisfully

automaticwithouttheneedforoperatorinterventionorsupervision.TheoutputsignalcanbesenttoFlow

Computers,SCADA,PLC’sortoaCentralControlRoomforloggingordisplayonchartrecordersormonitors.

TheKAM®OWD®sensoralsousesinternalreferencestoautocalibratefordriftcausedbytemperaturechangesof

theelectronics,theagingoftheelectronicscomponents,uidpressure,anduidtemperature.

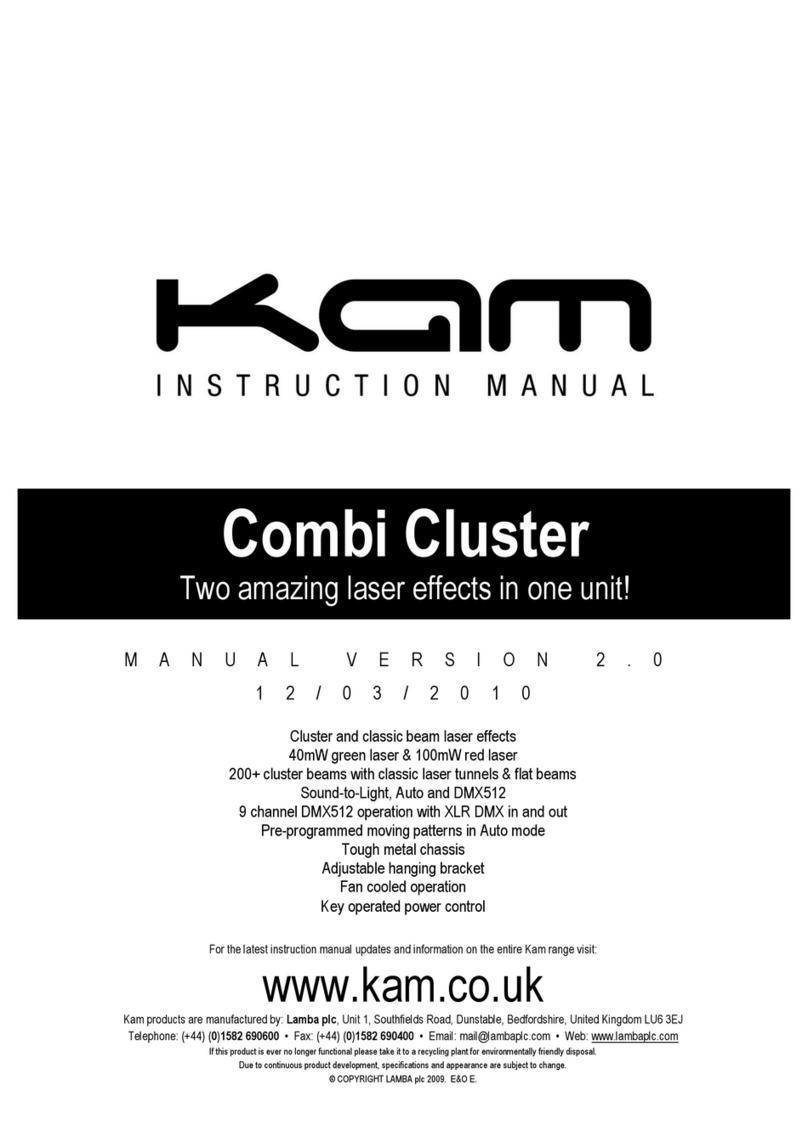

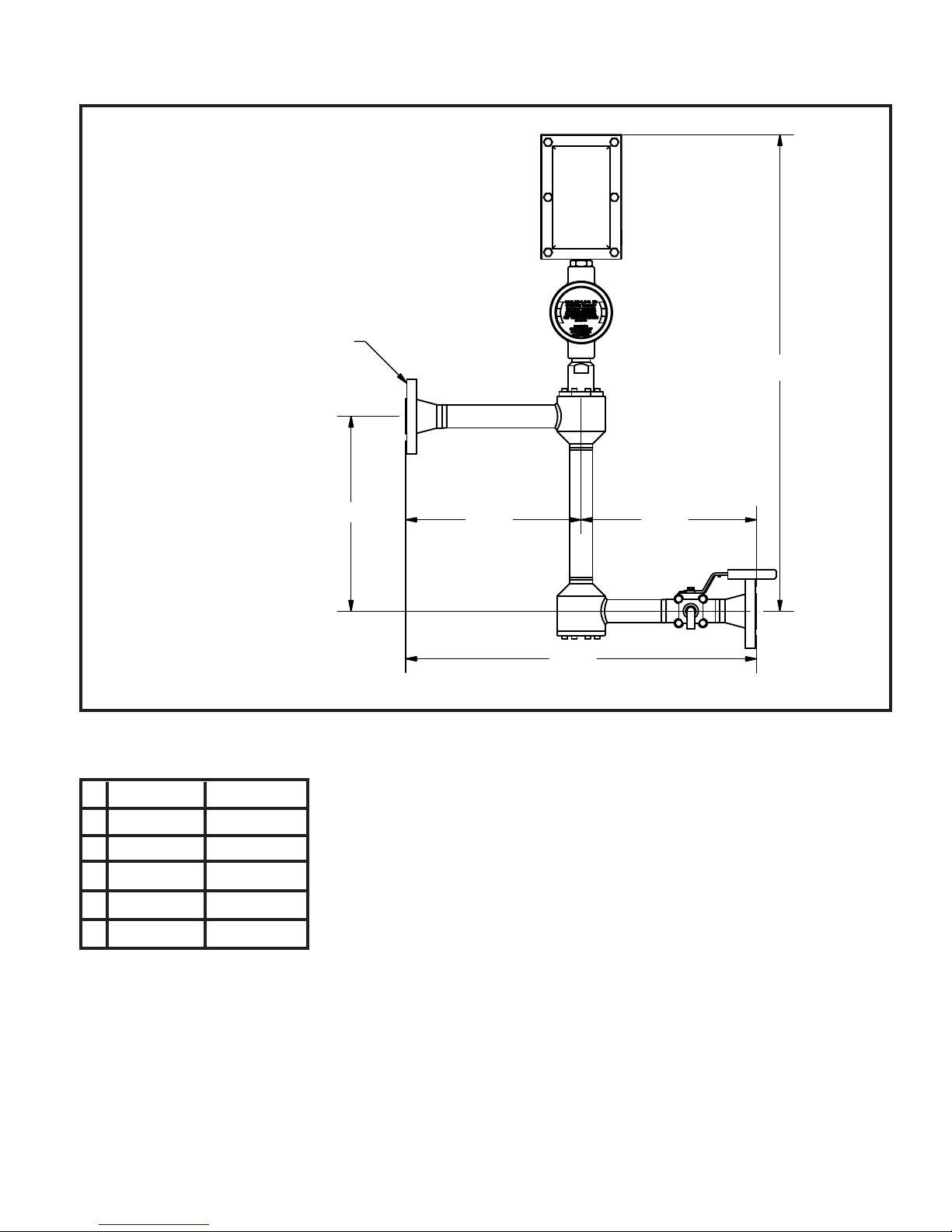

TheKAM®OWD®owthroughmodelcanbeusedinananalyzer/densitometerloop,forprocessoptimizationwhere

anaccuratedeterminationofwaterconcentrationisimportant,anditisvitaltooptimizingthe

desalinizationprocess.Placedonthedesaltersampleline,oroneachsampleline,theKAM®OWD®owthrough

modelprovidesreal-timeinformationaboutyourdesalterperformance.

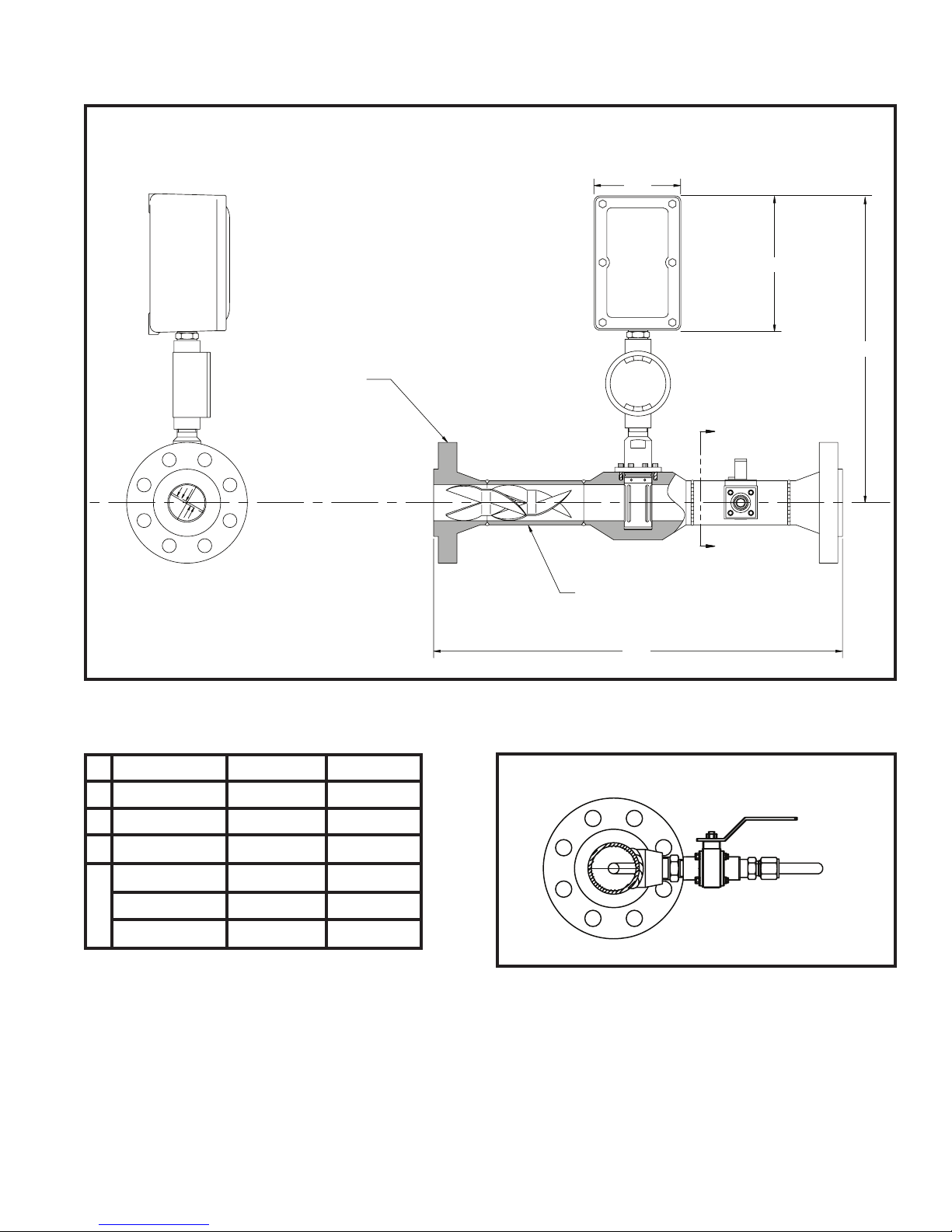

Toensurethehighestdegreeofaccuracy,theowmustbehomogenous.InstalledupstreamofyourOWD®

sensor,thepatentedKAM®SMP™StaticMixingPlateorKAM®SMS™StaticMixingSpoolcreateafully

homogenousmixtureinyourpipeline.Inlowvelocitysituations,theuseofaKAMMLMeasurementLoopmay

berequiredinordertocreateahomogenousowformeasurement.Propercalibration,alsokeytocomplete

accuracy,canbeachievedintheeldwiththeKAM®PKFPortableKarlFischerMoistureAnalyzer.

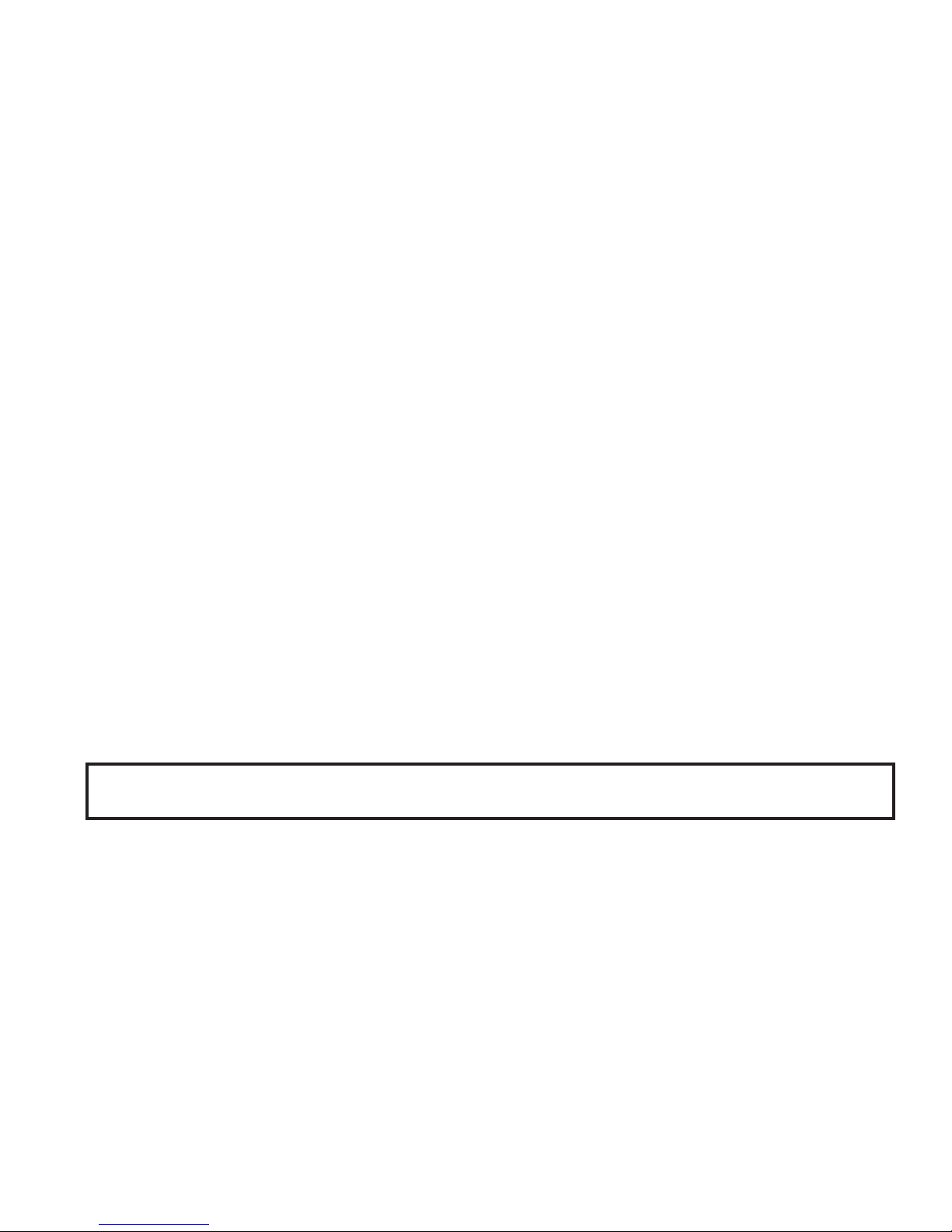

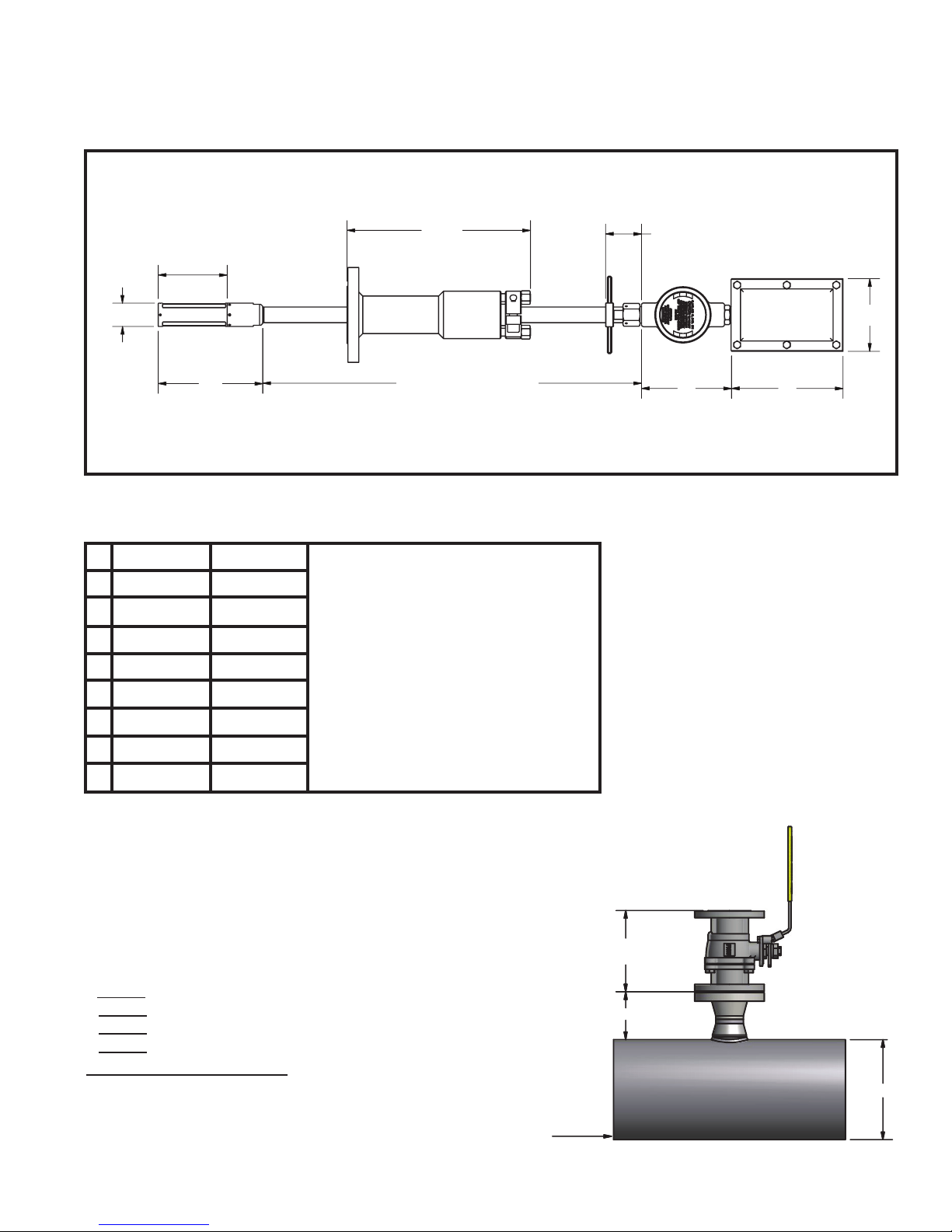

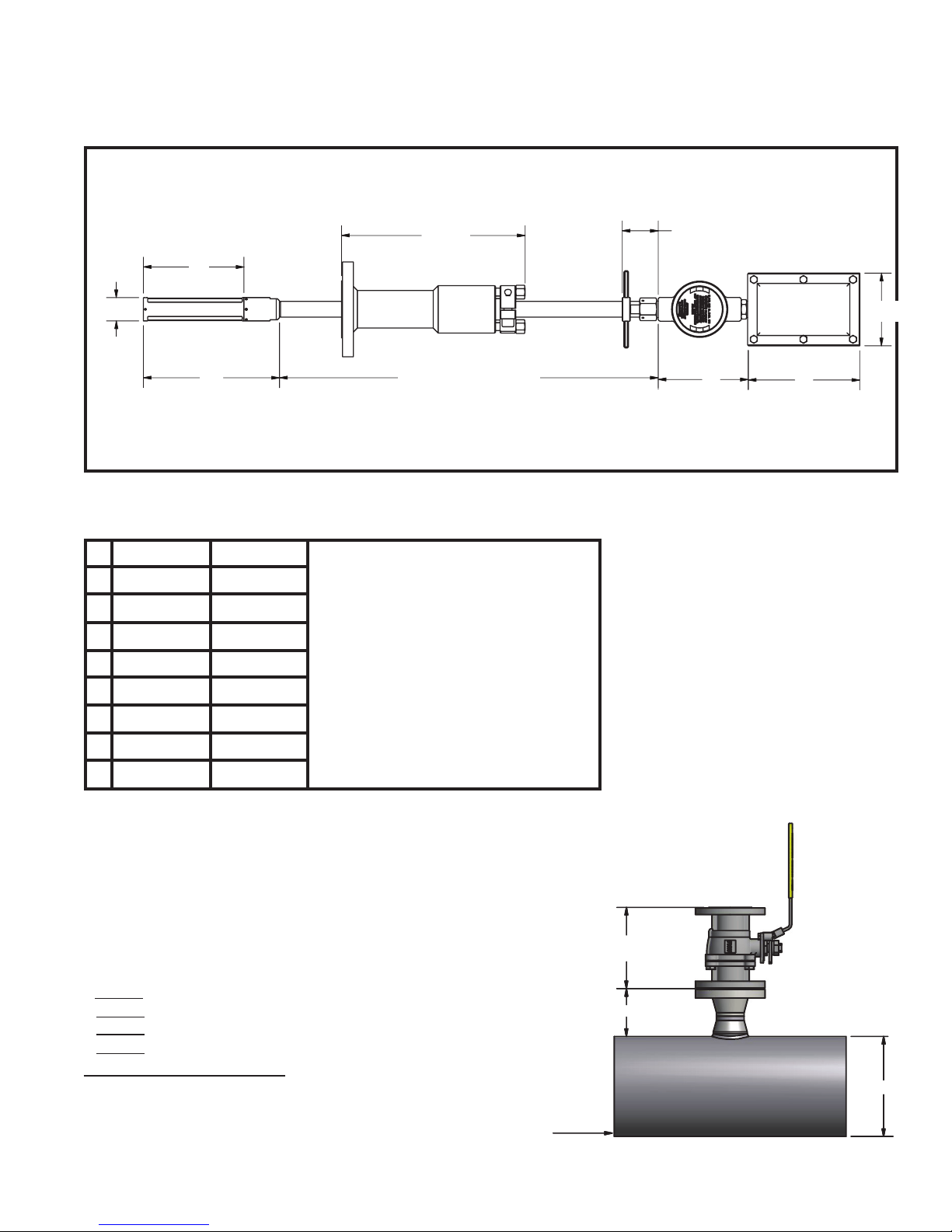

Becauseitcanbeinsertedintoyourpipeortankthrougha2",3",or4"hottap,theOWD®sensorhelpsyouavoid

costlydrainage,theneedforabypassloop,orhavingtocutasectioninthepipe.Allwettedpartsaremachinedfrom

316stainlesssteel.Shaftlengthsfrom1to3feetareavailablewithoff-the-shelflengthscomingin12",24",and36".

Metricandcustomlengthsareavailable.

Range(waterinoil) 0-1% 0–5% 0–10% 0–20% 0–40% 0–100%

Accuracy(atlistedrange)0.01% 0.05% 0.10% 0.20% 0.40% 1.00%

TABLE 1-5 MEASUREMENTCAPABILITIES:CALIBRATEDRANGEANDACCURACIES

NOTE:TheKAMOWDcanbecalibratedtoanyrangebetween0-1%and0-100%.

THEORY OF OPERATION