IASMANUAL 0821 KAM CONTROLS, INC.

4

SPECIFICATIONS

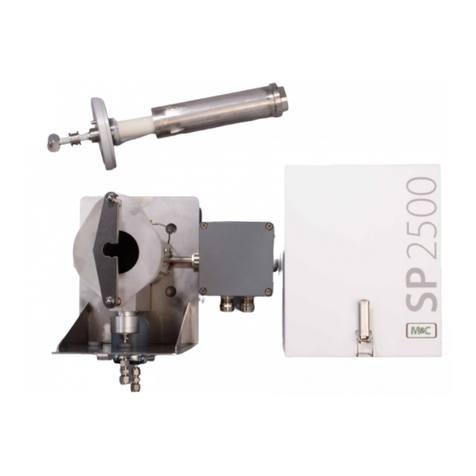

Media: Crude oil, refined products, chemicals, water and wastewater

Wetted parts: 316 stainless steel shaft and probe cage

304 stainless steel sample tube

PEEK bottom seal, Teflon available

Other materials available

Fluid temperature: -40º to 350ºF (-40º to 177ºC)

Power: Pneumatic, hydraulic

Sample size: 0.5 ml – 5 ml (per customer requirements)

Repeatability: Exceeds API 8.2 requirement

Mounting: Insertable/Retractable – 2" MNPT Seal Housing

Insertable/Retractable – 2", 3", or 4" Flanged Seal Housing

Flow Through – 1" or 2" Flow Through Spool

Pressure ratings: ANSI 150, 300, 600, 900*

Probe dimensions: Ø1.25" x 3.1" (32 mm x 79 mm)

Shaft length: 30" (762mm) for insertable/retractable models.

Pipe size: 1" to 42" (50 mm to 1067 mm)

Weight: From 30 lbs. (13.6 kg)

*Flow-through models only

REQUIREMENTS

Air: 70 to 125 psi

Consumption: 20 cubic inches per stroke

Maximum sample rate: 20 samples/minute