Technical manual KANMED Operatherm OP3

Page 2 of 34

INDEX

TECHNICAL MANUAL ......................................................................................................................................... 3

1INTENDED USE ....................................................................................................................................... 3

2EXPLANATION OF SYMBOLS USED .................................................................................................. 3

3SAFETY INFORMATION ........................................................................................................................ 4

Warnings .................................................................................................................................................................... 4

Caution ....................................................................................................................................................................... 4

4CLEANING, CHECKS BEFORE USE AND MAINTENANCE........................................................... 5

5ACCESSORIES AND SPARE PARTS ................................................................................................. 5

6TECHNICAL INFORMATION ............................................................................................................................ 7

General ....................................................................................................................................................................... 7

Detailed system description........................................................................................................................................ 7

7TECHNICAL DATA................................................................................................................................... 9

Classifications ............................................................................................................................................... 9

8SERVICE SOFTWARE............................................................................................................................. 10

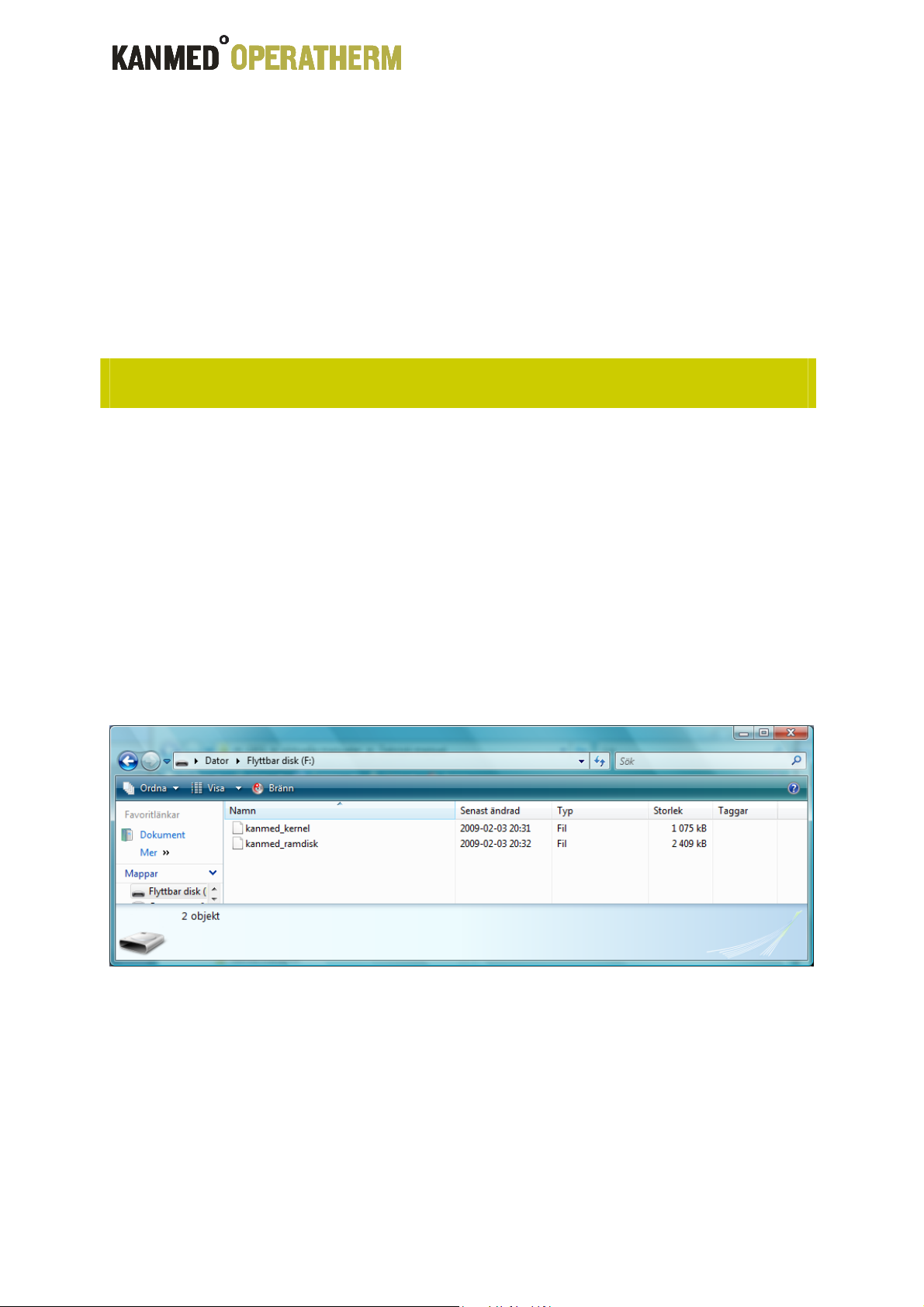

LOADING SOFTWARE TO THE CU. ................................................................................................................... 10

MENU functions .......................................................................................................................................... 12

Main Menu ............................................................................................................................................................... 12

System Settings ........................................................................................................................................................ 12

Set Time and date ..................................................................................................................................................... 12

Set Identifier............................................................................................................................................................. 12

Writing Logs to USB................................................................................................................................................ 13

Technical Data menu................................................................................................................................................ 16

Control Unit Summary ............................................................................................................................................. 16

Control Unit Calibration Data .................................................................................................................................. 16

Heating Pad Data Summary ..................................................................................................................................... 17

Heating Pad Calibration Data ................................................................................................................................... 17

System Measurements .............................................................................................................................................. 17

Control Unit Calibration Check................................................................................................................................ 18

Log Data Menu......................................................................................................................................................... 18

Control Unit Log ...................................................................................................................................................... 18

PAD Log .................................................................................................................................................................. 19

Special operation, workshop level only!................................................................................................................... 20

Control Unit RE-Calibration .................................................................................................................................... 20

8TROUBLE SHOOTING.......................................................................................................................... 21

Function Supervision and Alarms ............................................................................................................................ 21

Alerts ........................................................................................................................................................................ 21

Medium severity alarms ........................................................................................................................................... 22

High severity alarms................................................................................................................................................. 23

9ANNUAL CHECK OF THE SYSTEM.................................................................................................... 25

10 REPAIR INSTRUCTIONS OP3 CONTROL UNIT AND PAD............................................................. 26

CU Disassembling instructions: ............................................................................................................................... 26

CU Assembling instructions:.................................................................................................................................... 29

PAD Disassembling instructions: ............................................................................................................................. 30

11 WARRANTY........................................................................................................................................... 31

12 DISPOSAL............................................................................................................................................. 31

13 EMC COMPATIBILITY STATEMENT............................................................................................... 32

EMC Guidelines for the Operatherm OP3 system....................................................................................... 32