Index

Index ...............................................................................................2

Installation......................................................................................4

Box contents ............................................................................................ 4

Location................................................................................................... 4

Leveling ................................................................................................... 5

Connection............................................................................................... 5

Compatibility with the older K1 model ....................................................... 5

Questions ?.............................................................................................. 5

Introduction....................................................................................6

The fusion theory ..................................................................................... 6

Automatic fluxers ..................................................................................... 6

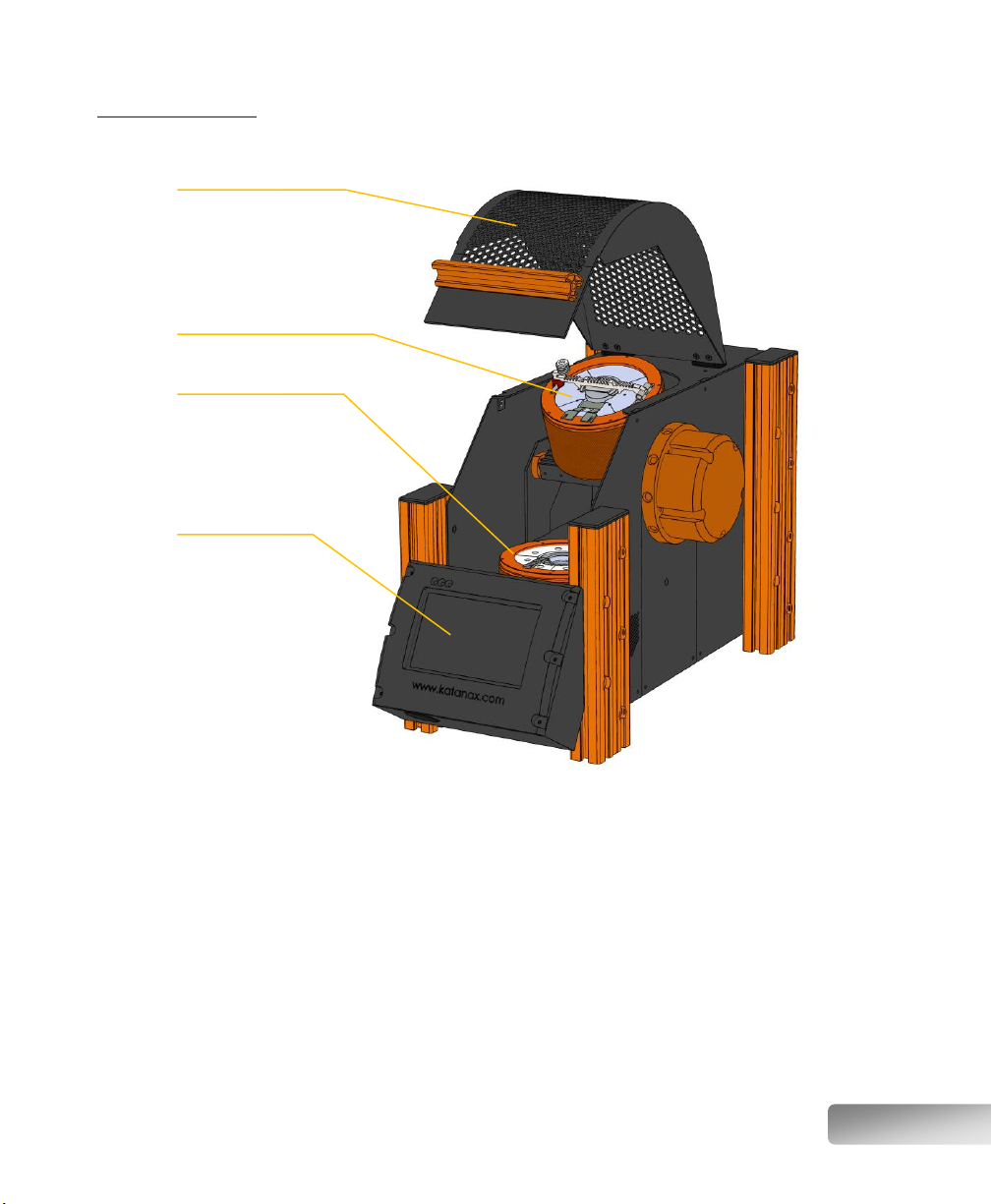

The K1 Prime fluxer.................................................................................. 7

Main features of the Katanax K1 Prime.................................................... 10

Precautions ...................................................................................12

High temperature................................................................................... 12

High voltage........................................................................................... 12

Acid spills............................................................................................... 12

Heavy instrument................................................................................... 12

Crucible locking ...................................................................................... 12

How the unit works ......................................................................13

Heating.................................................................................................. 13

Agitation and pouring of the melt ............................................................ 13

Cooling .................................................................................................. 13

Solution agitation ................................................................................... 13

Using the K1 Prime (basic) ..........................................................15

The main running screen ........................................................................ 15

During a fusion....................................................................................... 17

The right ingredients .............................................................................. 18

Care of the elements .............................................................................. 21

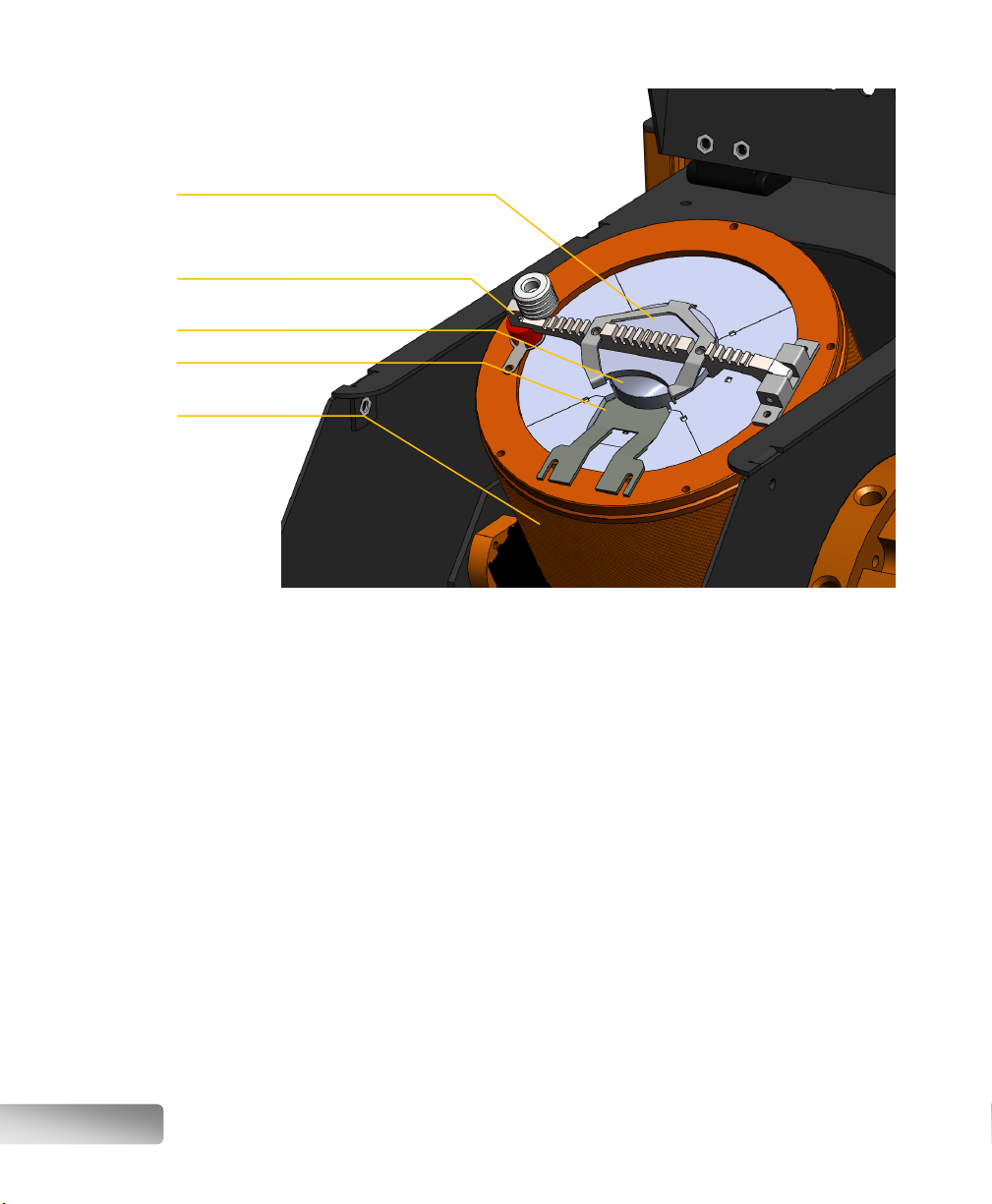

Crucible installation ................................................................................ 22

Mold installation ..................................................................................... 22

A general fusion ..................................................................................... 22

Making solutions..................................................................................... 23

Description of the fusion steps ................................................................ 24

Programming the K1 Prime (advanced)......................................27

Viewing the fusion parameters ................................................................ 27

Unlocking the advanced mode ................................................................ 31

Managing fusion methods ....................................................................... 31

Preparing a fusion program..................................................................... 32

Heating steps ......................................................................................... 32

Pouring step........................................................................................... 33

Cooling steps ......................................................................................... 34