(T218731-001-0E)

Table of contents 218731

Introduction ………………………………………………………………………………………… [1]

How to use this manual …………………………………………………………………………… [2]

Inspection and servicing …………………………………………………………………………… [3]

Serial number nameplate ………………………………………………………………………… [3]

Operationqualifications …………………………………………………………………………… [3]

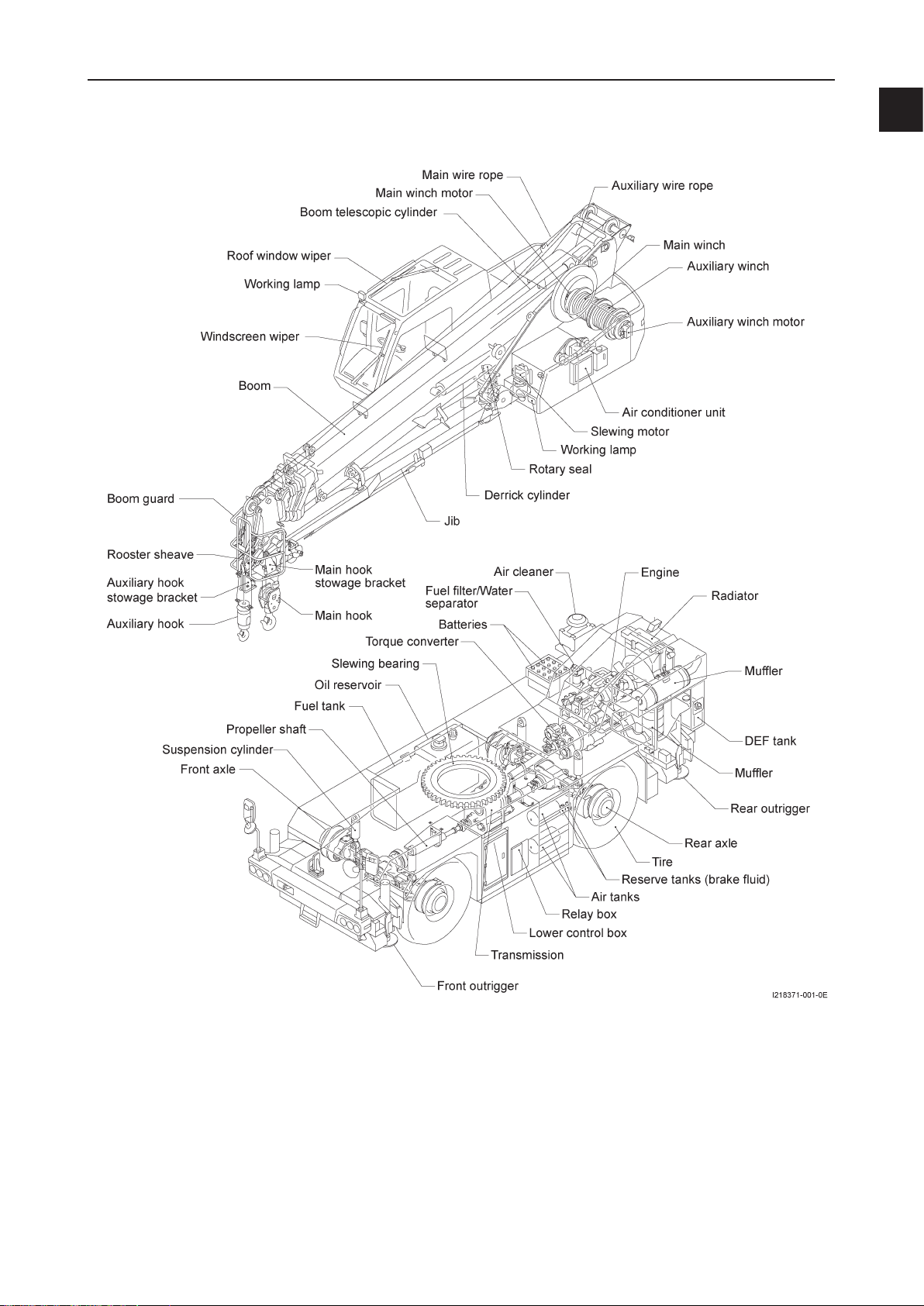

1. Part names …………………………………………………………………………………… 1

2. Precautions on inspection and servicing …………………………………………………… 3

2-1 Information marked "DANGER" …………………………………………………………………………… 3

2-2 Information marked "WARNING" ………………………………………………………………………… 4

2-3 Information marked "CAUTION" …………………………………………………………………………… 13

3. Inspection and servicing table ……………………………………………………………… 15

3-1 Drive-related ………………………………………………………………………………………………… 16

3-2 Crane-related ………………………………………………………………………………………………… 22

4. Lubrication ……………………………………………………………………………………… 26

4-1 Precautions on lubrication …………………………………………………………………………………… 26

4-2 Oils that have been filled upon shipment from our factory ………………………………………………… 28

4-3 Recommended lubricants table ……………………………………………………………………………… 30

4-4 Greasing chart ……………………………………………………………………………………………… 31

4-5 Oil chart ……………………………………………………………………………………………………… 41

5. Inspection and servicing of each part ……………………………………………………… 42

5-1 Engine-related ……………………………………………………………………………………………… 42

5-2 Power transmission system ………………………………………………………………………………… 54

5-3 Drive system ………………………………………………………………………………………………… 58

5-4 Braking system ……………………………………………………………………………………………… 63

5-5 Steering system ……………………………………………………………………………………………… 70

5-6 Shock absorbers ……………………………………………………………………………………………… 71

5-7 Hydraulic system-related …………………………………………………………………………………… 72

5-8 Boom-related ………………………………………………………………………………………………… 84

5-9 Winch-related………………………………………………………………………………………………… 91

5-10 Slewing-related ……………………………………………………………………………………………… 98

5-11 Air conditioner-related …………………………………………………………………………………… 100

5-12 Electrical system-related ………………………………………………………………………………… 107

5-13 Crane safety devices ……………………………………………………………………………………… 113