[3] CRANE STOWING OPERATION

1. Completely retract the boom and slew until the boom is over the center of the crane. Lower the boom to the

maximum (it stops automatically).

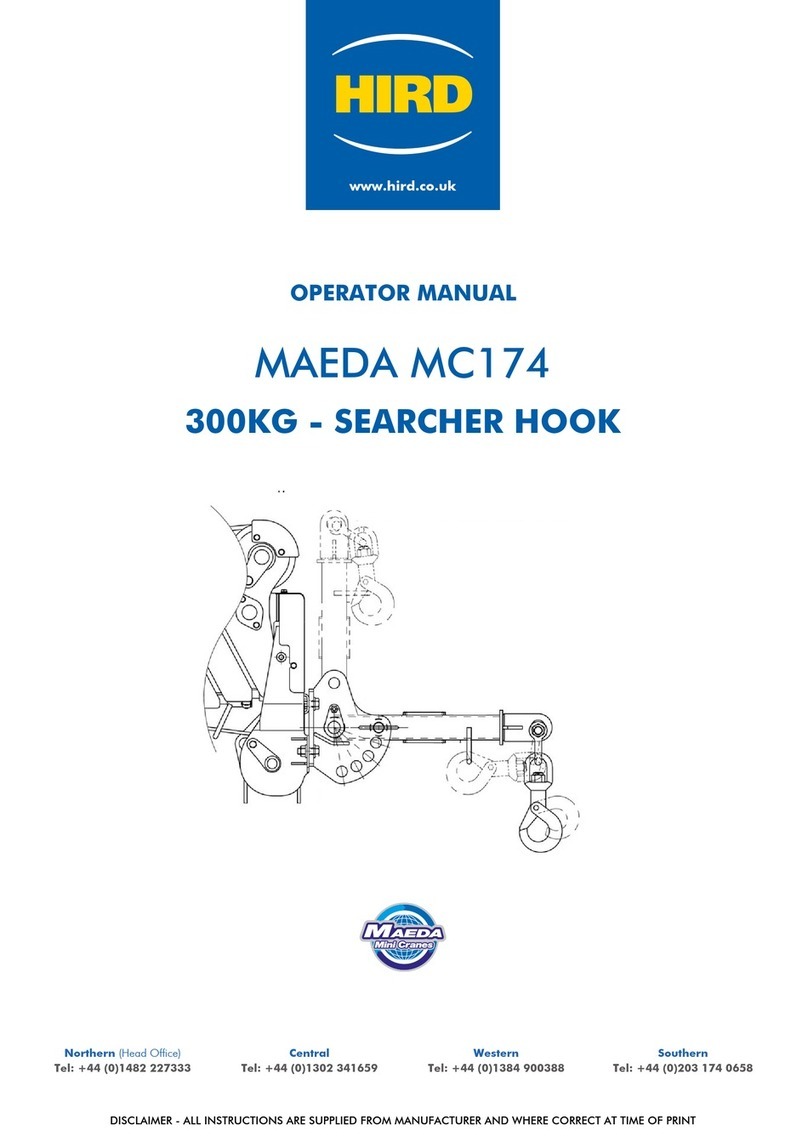

2. Attaching the hook block in the hook hanger:

Hoist up the hook block to the over hoist protection. Attach the hook to the hanger and raise the hook block using the

over hoist DETECTOR (see drawing) and simultaneously pull the winch lever towards you.

3. Warning : Be careful with the over hoist detector. The hook block will not stop automatically, so don’t apply to much

tension, but apply enough tension to stop the hook block from moving .

7. MOMENT LIMITER (OVERLOAD DETECTOR)

MOMENT LIMITER FUNCTIONS

[1] PROHIBITED ACTIONS AFTER AUTO STOP

The following crane operations are prohibited after the crane has stopped automatically due to overloading.

These operations may cause overturning of the machine or breakage of the boom and are very dangerous.

• Boom lowering operation • Boom extending operation • Hook raising operation

• Crane slewing operation

[2] OVERLOAD WARNING

1. PRE-WARNING:

“Actual load” is 70 to less than 100 % of the “rated total load”.

• The LED “70~100” on the moment limiter display lights up.

• The alarm bleeps intermittently.

• The working status lamp changes from green to yellow.

2. LIMIT WARNING:

“Actual load” is 100 % or higher than the “rated total load”.

• The LED “100~” on the moment limiter display lightsup.

• The alarm sounds continuously.

• The working status lamp changes from yellow to red.

• The hazardous operation of the crane stops automatically.

(Hook raising, boom lowering, boom extending)

3. RECOVERY OPERATIONAFTERAUTO STOP

If the system stops automatically, promptly perform one offollowing the recovery operation caused by overloading.

(1) Hook lowering operation

(2) Boom raising operation (never raise the boom to lift the load from the ground, always winch the load clear of the

ground before any other operation is performed)

(3) Boom retracting operation

-7-