KATflo 100 Table of Contents

KATflo 100

Operating Instructions

Table of Contents

age

1 Safety instructions, legal requirements, warranty, return policy.................5

1.1 Symbols used in these operating instructions.............................................5

1.2 Safety instructions....................................................................................... 5

1.3 Warranty...................................................................................................... 6

1.4 Return policy............................................................................................... 6

1.5 Legislative requirements............................................................................. 6

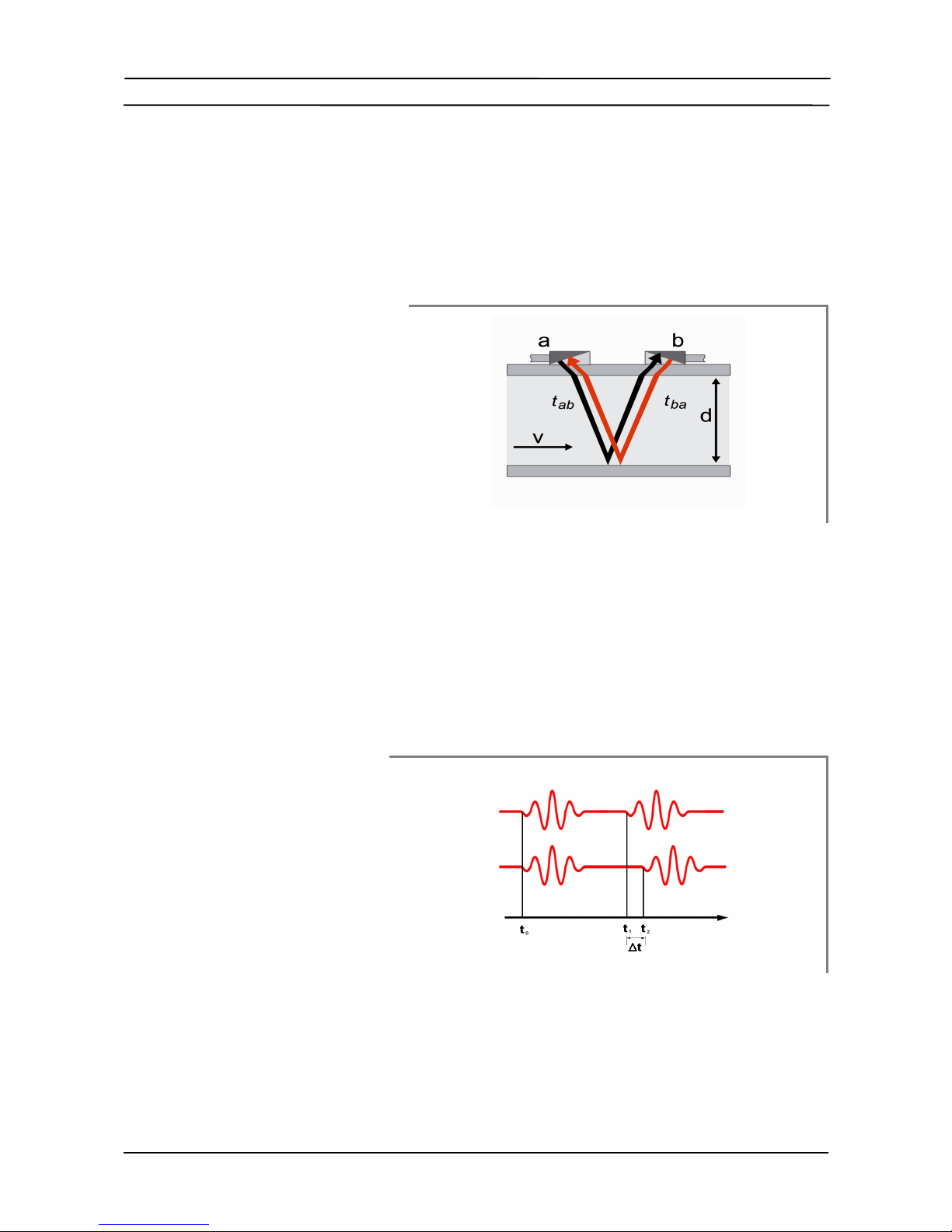

2 Introduction...................................................................................................... 7

3 Installation........................................................................................................ 8

3.1 Unpacking and storage............................................................................... 8

3.1.1 Unpacking............................................................................................ 8

3.1.2 Storage ................................................................................................ 8

3.1.3 Identification of components................................................................. 8

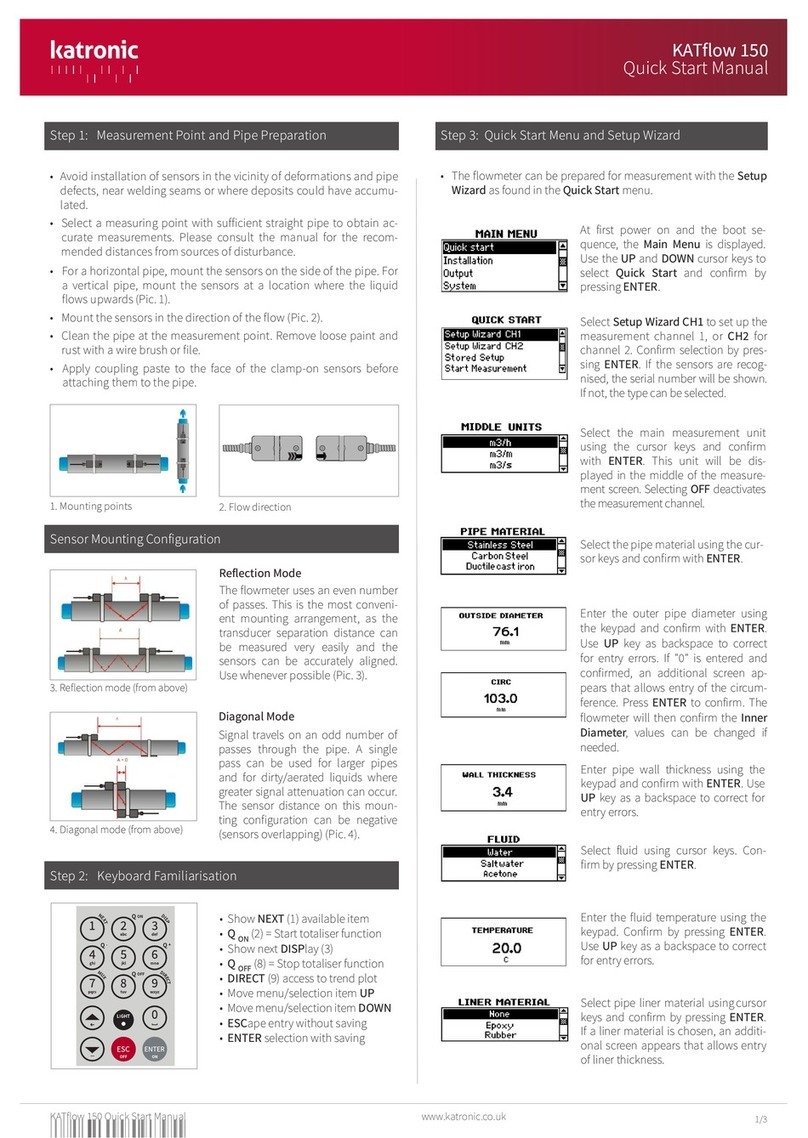

3.2 Clamp-on sensor installation....................................................................... 9

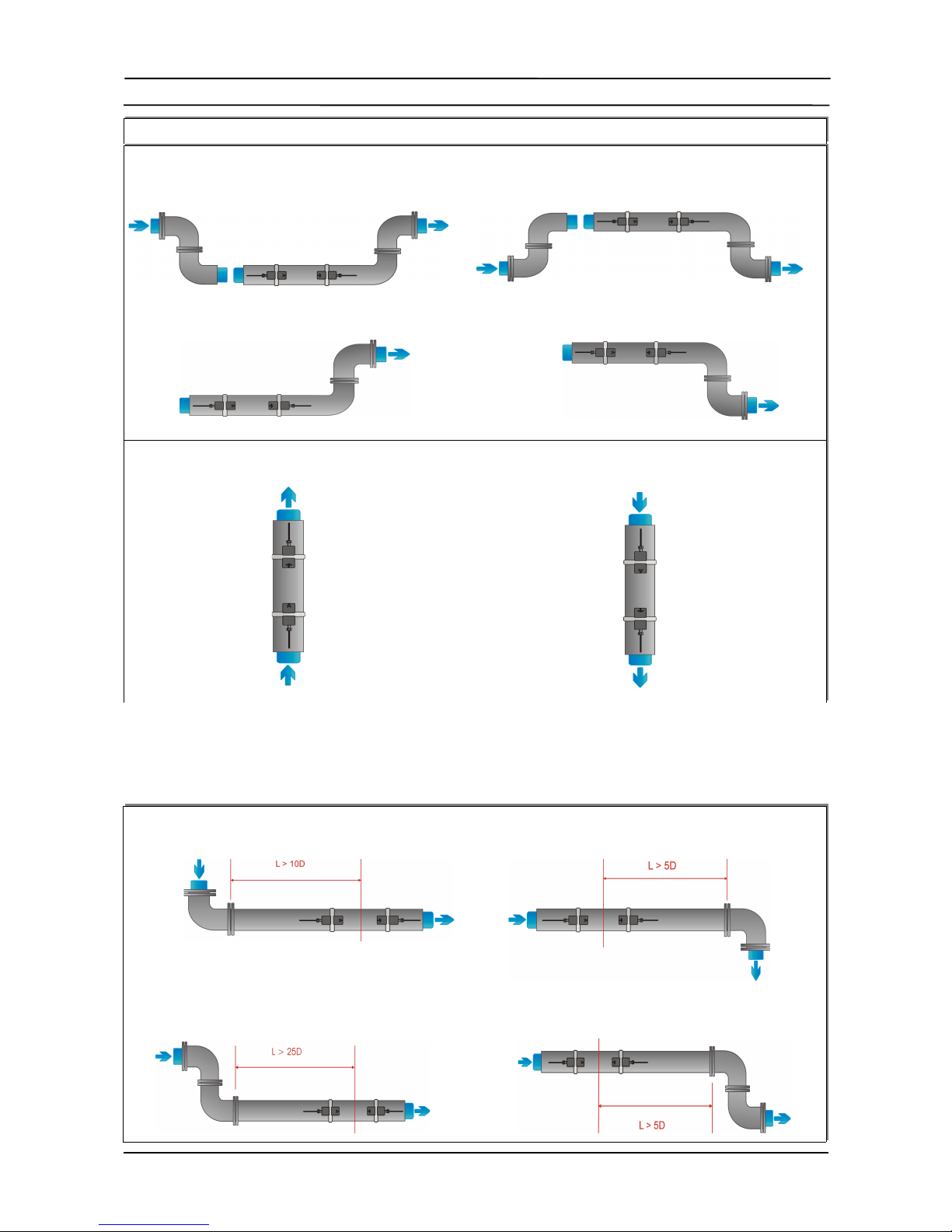

3.3 Installation location...................................................................................... 9

3.4 Pipe preparation.......................................................................................... 12

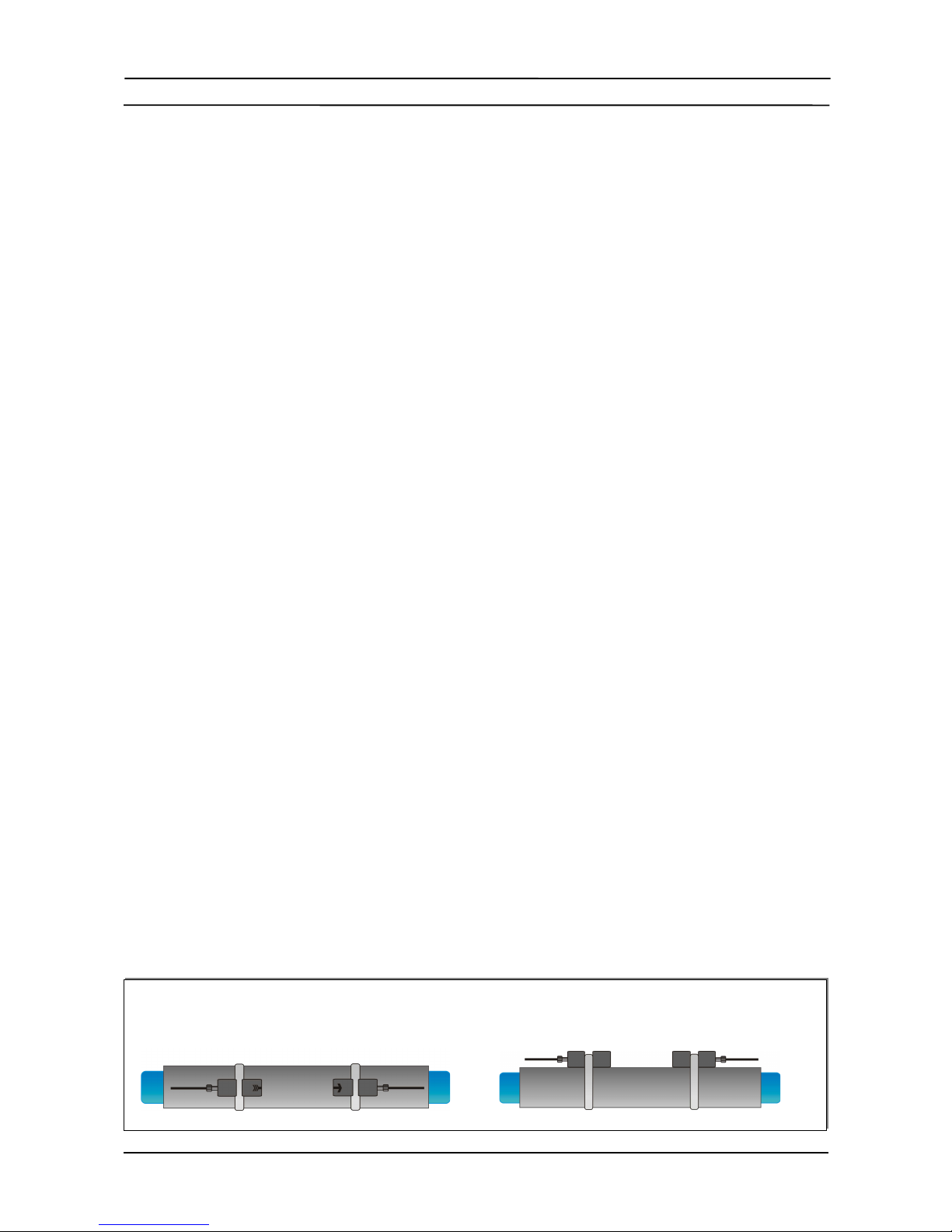

3.5 Clamp-on sensor mounting configurations and separation distance...........12

3.6 Flo meter installation.................................................................................. 13

3.6.1 Wall mounting....................................................................................... 13

3.6.2 Electrical connections........................................................................... 1

3.7 Clamp-on sensor mounting......................................................................... 16

3.7.1 Sensor pipe mounting configurations................................................... 16

3.7.2 Acoustic coupling gel............................................................................ 16

3.7.3 Correct positioning of the sensors........................................................ 17

3.7.4 Sensor mounting with tension straps....................................................17

4 Operation.......................................................................................................... 19

4.1 S itching On/Off......................................................................................... 19

4.2 Keypad and display..................................................................................... 19

4.2.1 Keypad key functions........................................................................... 19

4.2.2 Display functions.................................................................................. 21

4.3 Quick setup izard...................................................................................... 22

4.4 Measurements............................................................................................. 25

4.4.1 Main process value (PV) display.......................................................... 2

4.4.2 Diagnostic displays............................................................................... 26

4.4.3 Totalisers.............................................................................................. 26

4.4.4 Datalogger............................................................................................ 26

5 Commissioning................................................................................................ 27

5.1 Menu structure............................................................................................ 27

5.2 Diagnostics.................................................................................................. 31

5.3 Display settings........................................................................................... 31

5.4 Output configuration.................................................................................... 33

.4.1 Serial interface RS 232.........................................................................33

.4.2 Serial interface RS 48 .........................................................................33

.4.3 HART output......................................................................................... 33

.4.4 Analogue current output ...................................................................... 34

3