Kawai SK-7 Reference guide

Other Kawai Musical Instrument manuals

Kawai

Kawai CP95 User manual

Kawai

Kawai MP4 User manual

Kawai

Kawai ES4/es1P User manual

Kawai

Kawai Concert Performer Series Digital Piano CP117 User manual

Kawai

Kawai MP6 User manual

Kawai

Kawai DX500 User manual

Kawai

Kawai LH-1 User manual

Kawai

Kawai CL20 User manual

Kawai

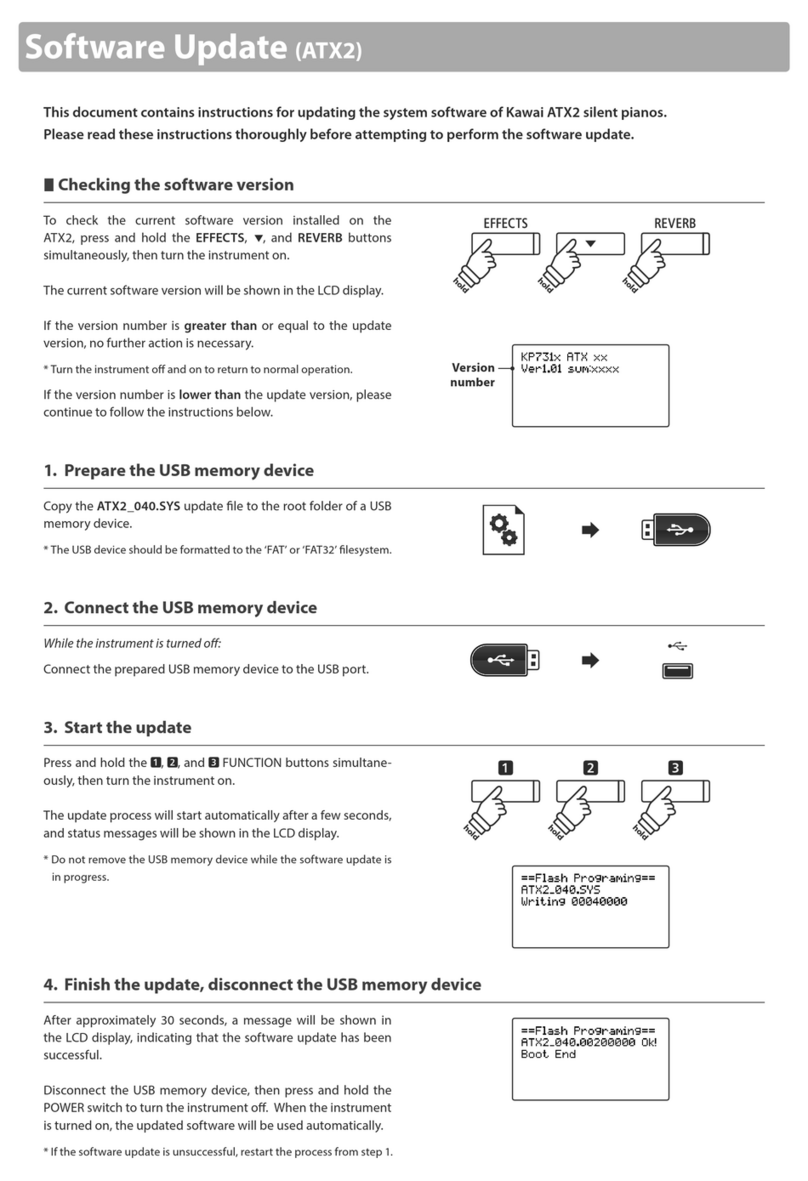

Kawai ANYTIME ATX2 Technical manual

Kawai

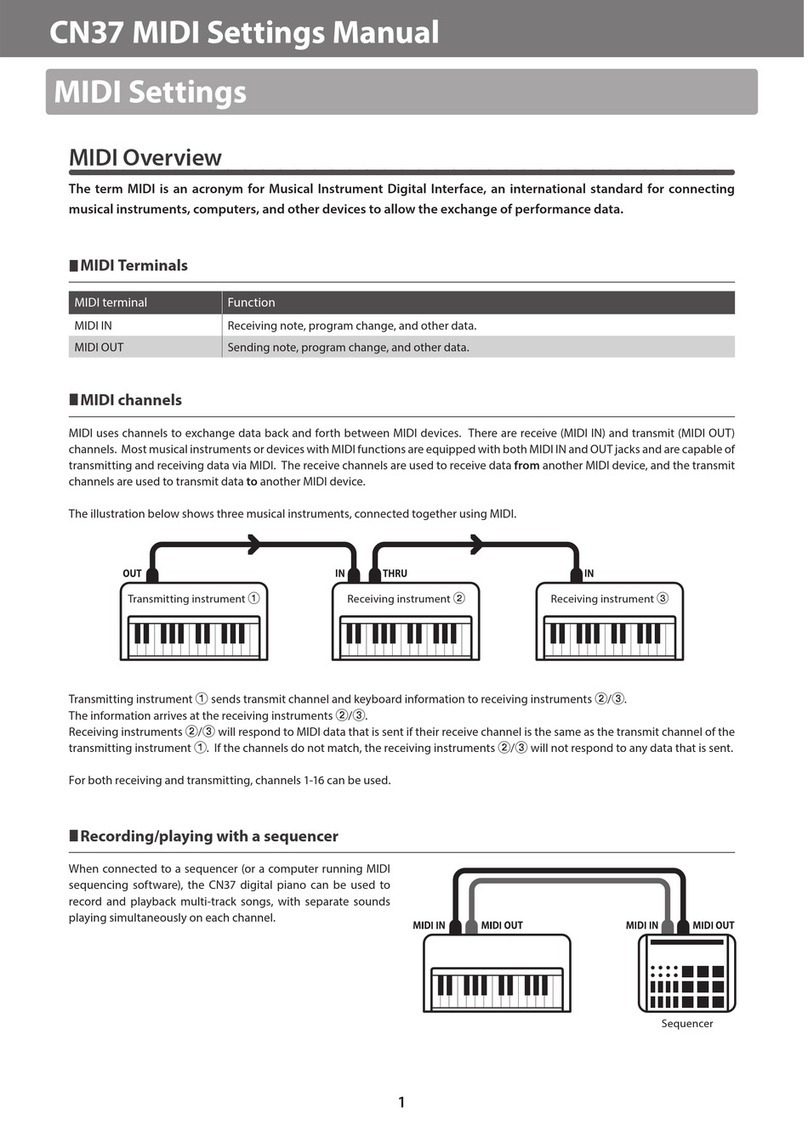

Kawai CN37 Manual

Kawai

Kawai CP116 User manual

Kawai

Kawai DX80 User manual

Kawai

Kawai EGP-10 Grand E1 User manual

Kawai

Kawai ES8 User manual

Kawai

Kawai CS10 User manual

Kawai

Kawai CN27 User manual

Kawai

Kawai KDP110 User manual

Kawai

Kawai Concert Performer CP205 User manual

Kawai

Kawai AnytimeX User manual

Kawai

Kawai MP4 User manual