V4.00

25833_EDEBDA0290-4620-1_EN

6

1.3 Safety notes

In order to prevent operating errors, device operation is kept as simple as possible.

This will enable you to start your device up quickly.

It is in your own interest to read the following safety instructions carefully. The applicable

DIN/VDE regulations must be observed during installation!

Power supply connection, setup and operation of the device must be performed by

qualied personnel only. Qualied personnel as dened in the safety notes in this user

manual are those authorized to set up, ground and mark devices, systems and circuits in

accordance with applicable standards and regulations.

To prevent re and electric shock, do not expose the device to rain or moisture!

Before connecting the device to the power supply, check whether the local power supply

conditions comply with the specications on the device nameplate.

CAUTION

Incorrectly connecting the device can damage it!

For device connection, the data given in the connection diagram must be complied with

(see chapter “Connection diagram”) and the connection lines must be voltage-free. When

wiring, always ensure that all wiring material used is neither damaged nor defective and

that the polarity is correct!

Proper and safe operation of the product requires correct transport, storage, installation

and assembly as well as careful operation and maintenance.

If the device has any visible damage it is considered unt for use and must be disconnect-

ed from the mains!

Troubleshooting, repairs and maintenance work may only be carried out at our plant or

after contacting our customer service team. If the device is opened without authoriza-

tion, any warranty or guarantee claim is forfeited. Correct functioning can no longer be

guaranteed!

Opening the device may expose live parts. Capacitors in the device may still be charged,

even if the device has been disconnected from all power sources. Do not operate open

devices under any circumstances!

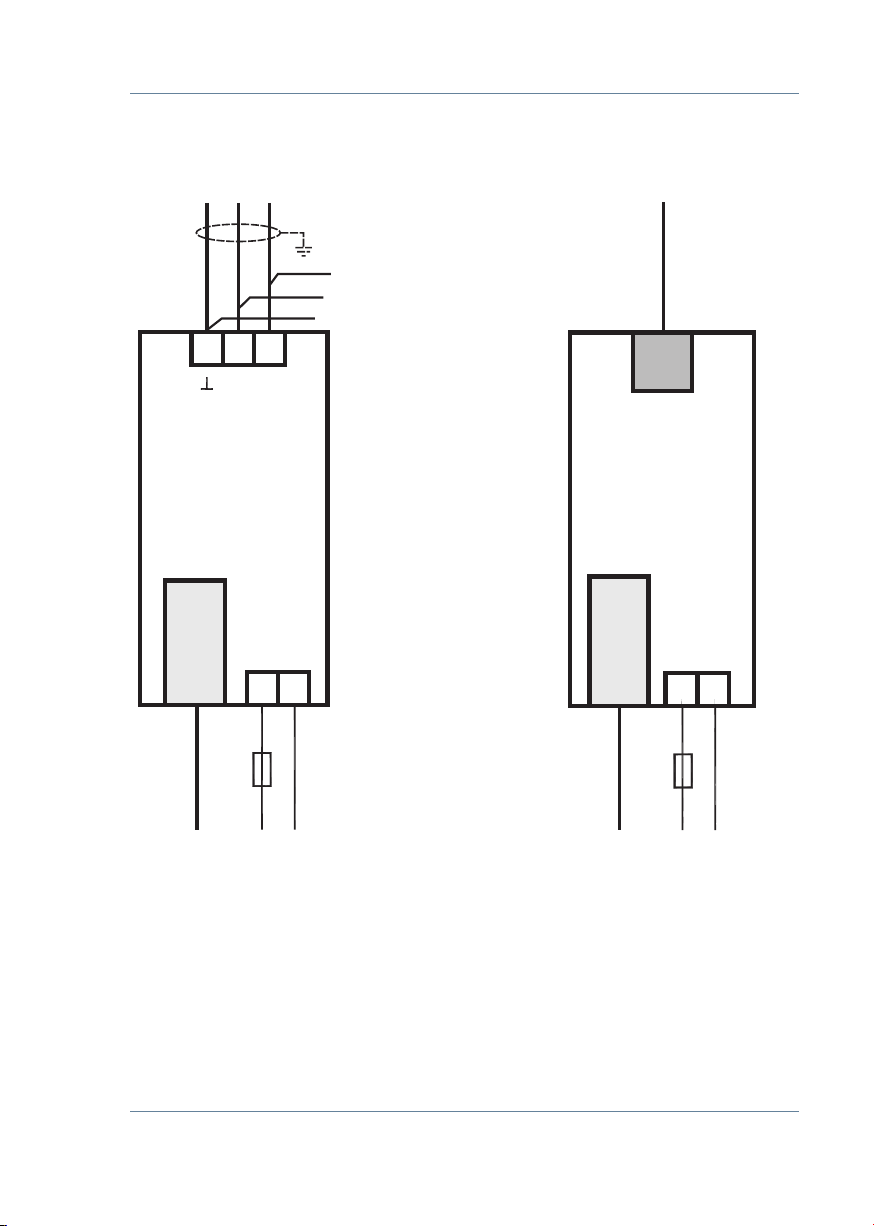

Systems that are at risk from lightning strikes must feature lightning protection for all

input and output lines.

Introduction