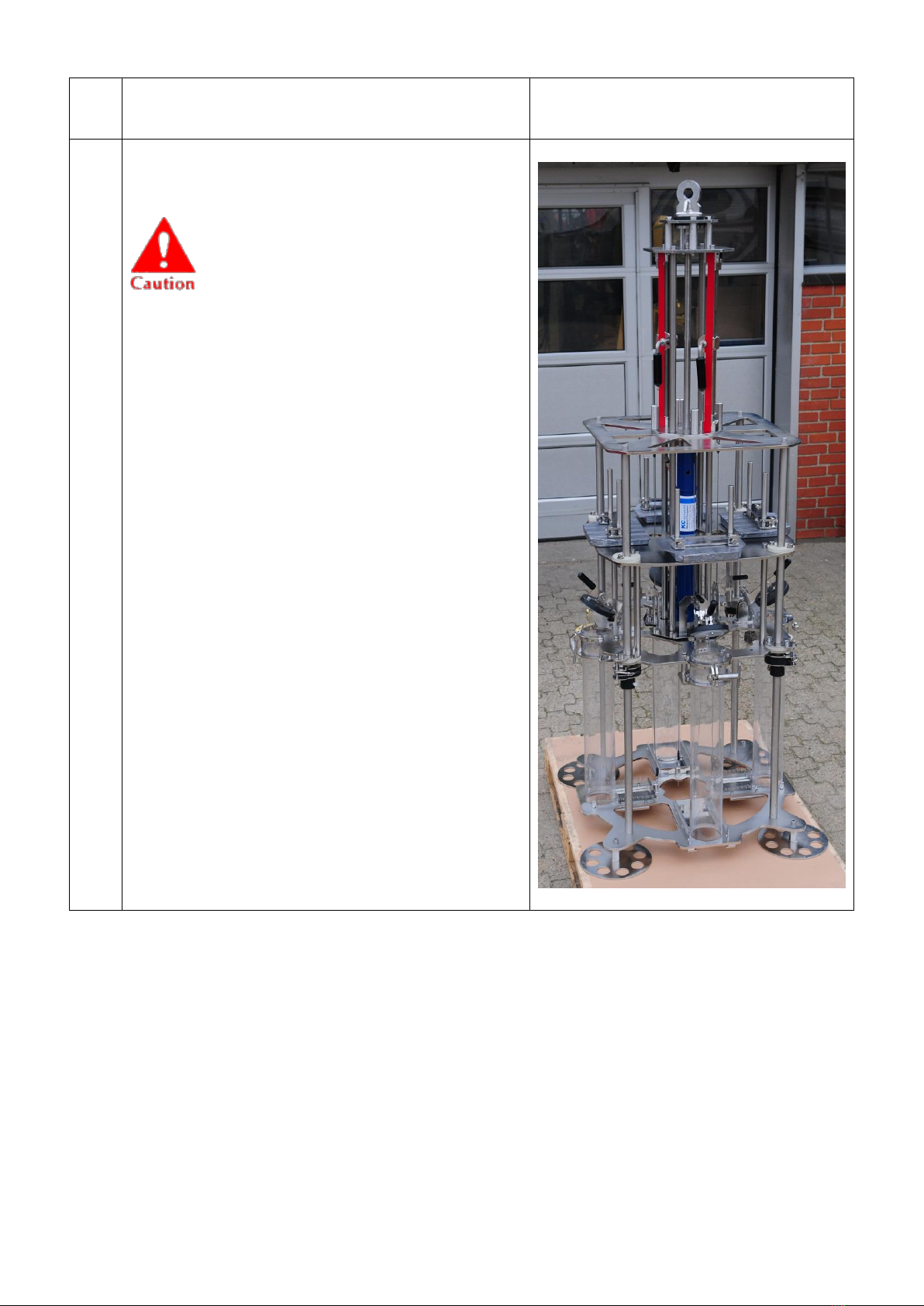

This multi corer is very dangerous in

unskilled hands and serious

precautions must be taken to avoid

accidents.

The safety clamp must always be in

the secured position and must be

released only, when the multi corer

is outside the rail of the boat. Except

for item #5 (water filling of

hydraulic damper).

KC Denmark A/S is not, and cannot

be held, responsible for any

damage(s) made to equipment or to

operators who ignore safety

precautions or because of misuse or

wrong operation.

Never walk under the multi corer,

when lifted up by the winch.

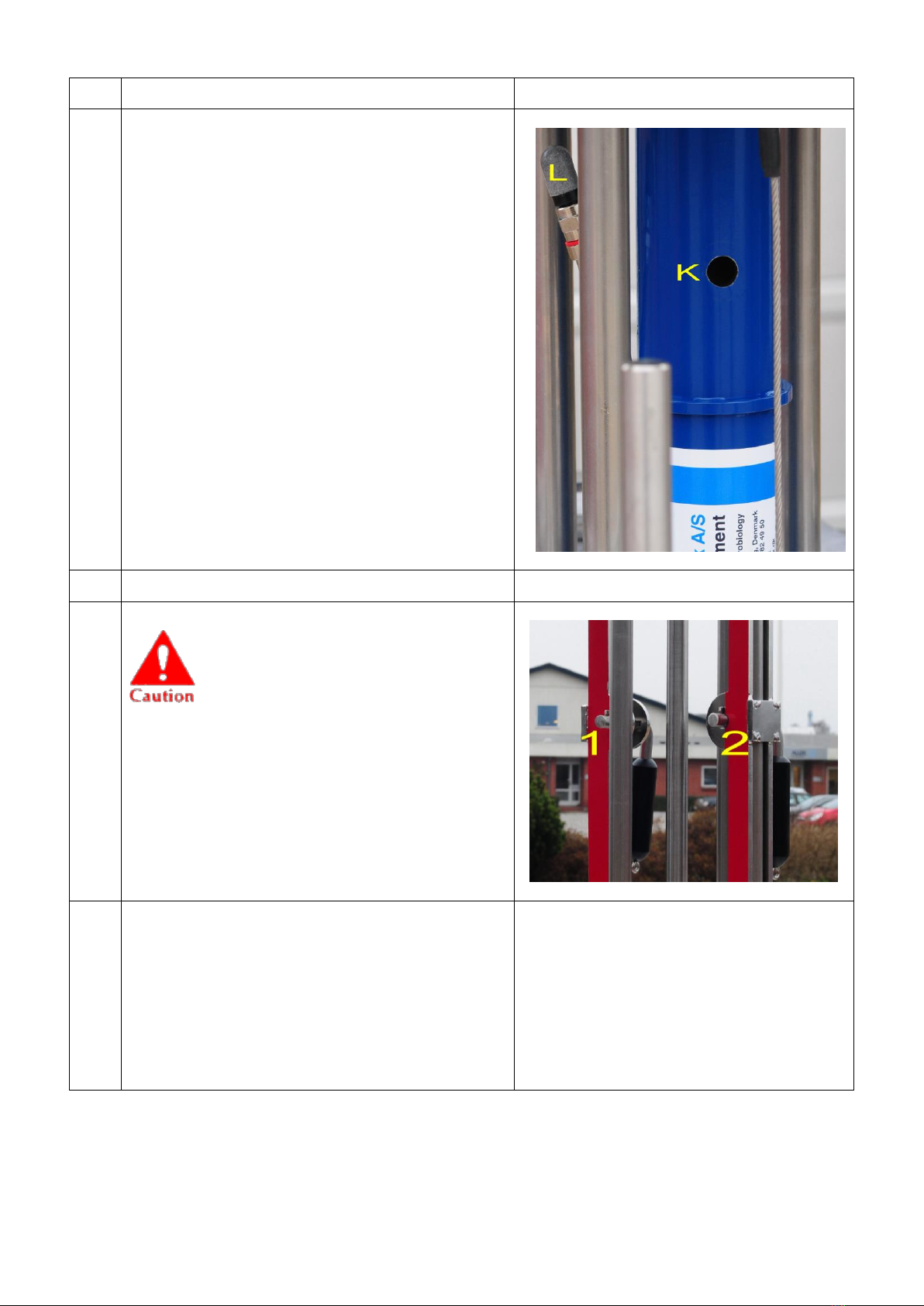

The photo shows another model with

2 pcs of safety clamps.