Benchy –Glycol Instruction Manual

Page 9of 9www.KegLand.com.au Last Updated 14/12/2020 5:29 PM

Balancing Your Benchy Dispensing System with CO2

The pressure to be set on your regulator differs according to the temperature that the keg is stored

at. If the product is stored at a higher temperature it will require a higher pressure to maintain the

desired level of carbonation. Refer to a carbonation chart to determine what pressure you should be

setting your regulator at to reach your desired level of carbonation based on the ambient

temperature the keg is stored in.

For most styles of beer, you should be aiming for a carbonation level of between 2.3-2.8 volumes of

carbonation with the average carbonation level being 2.6 volumes (if you are unsure of the

carbonation level of the beer i.e. if it is a commercial keg then assume it is at 2.6 volumes of

carbonation). To achieve a specific carbonation level during carbonation or priming refer to the table

in the link below and correlate the temperature of the keg with the desired carbonation level.

KegLand Carbonation Chart

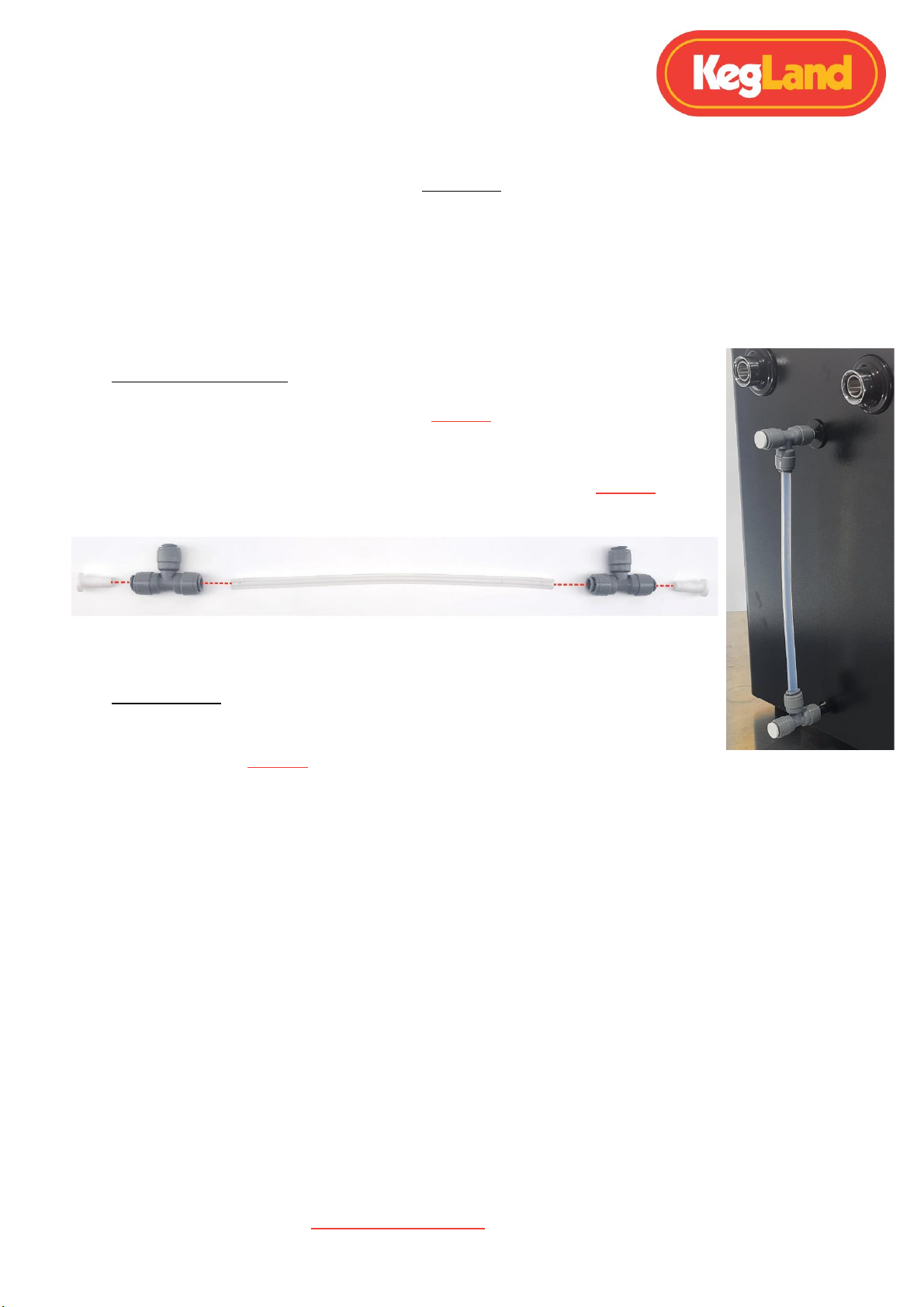

NOTE: Do not try to fix a slow or fast pour rate by adjusting the dispensing pressure. This will result

in your beer either going flat or over carbonated. It is best to adjust the beverage line length and

diameter. If the pour is too fast and is producing a lot of froth then increase the length of the

beverage line between the Benchy and the keg. Alternatively, if the pour is too slow then decrease

the length of the beverage line between the Benchy and the keg.

When adjusting your beverage line length to achieve the perfect pour it is always best to start with a

longer length of beverage line as you can always trim a longer length of hose.

Alternatively, you could use a short length of beer line and then a flow control tap (KL15523) or flow

control ball lock disconnect (KL09041) to reduce the flow rate.

MAINTENANCE

If the glycol solution has been stored for an extended period of time then it is suggested to replace

the solution, despite glycol having antimicrobial properties. It is recommended to replace the glycol

if it has changed colour dramatically or between 12 to 24 months of usage. To replace the glycol

solution empty the reservoir using the drainage port and then refill with the required concentration

of glycol using a refractometer to confirm the concentration.