Keg Types ............................................................................................................................................5

Commercial style kegs .....................................................................................................................5

Keg coupler assembly ..................................................................................................................5

How to use keg couplers. .............................................................................................................6

Alternative ways to connect EVABarrier tube to a keg coupler ....................................................6

Homebrew style kegs.......................................................................................................................6

Attaching EVABarrier tube to a barbed disconnect ......................................................................7

Attaching EVABarrier tube to an MFL disconnect.........................................................................8

Removing EVABarrier tube from a duotight fitting.......................................................................8

Beer line diameter and length correlation ...........................................................................................8

Balancing your keg system with CO2................................................................................................9

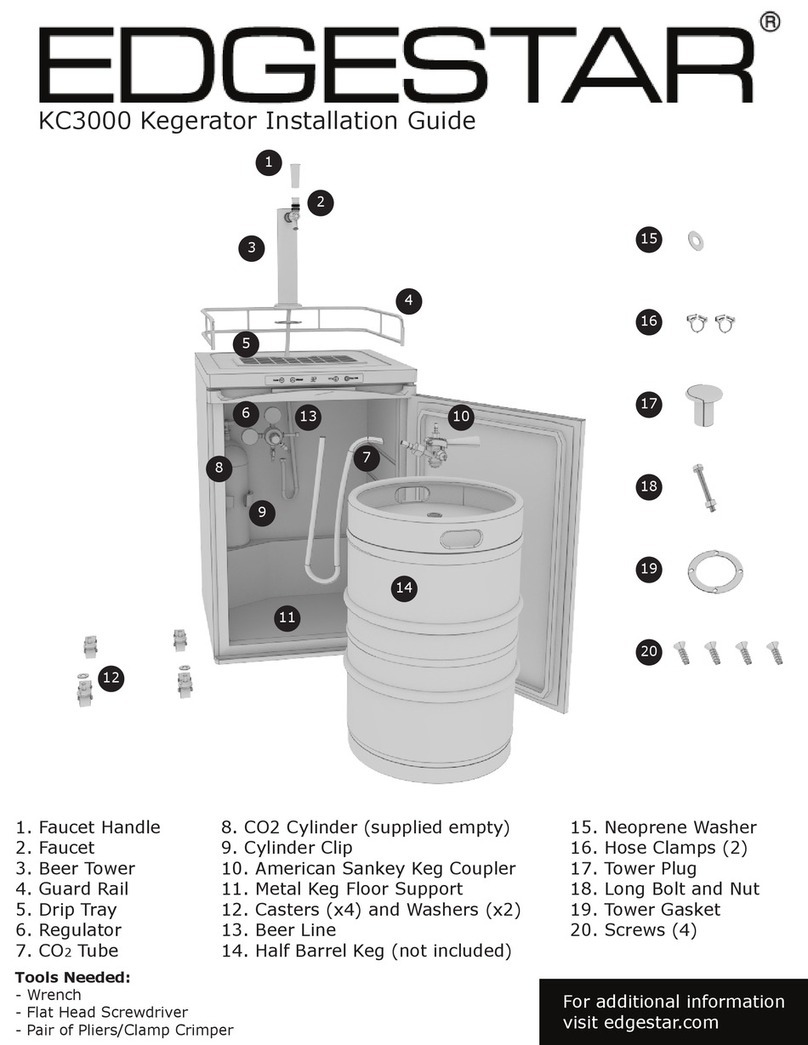

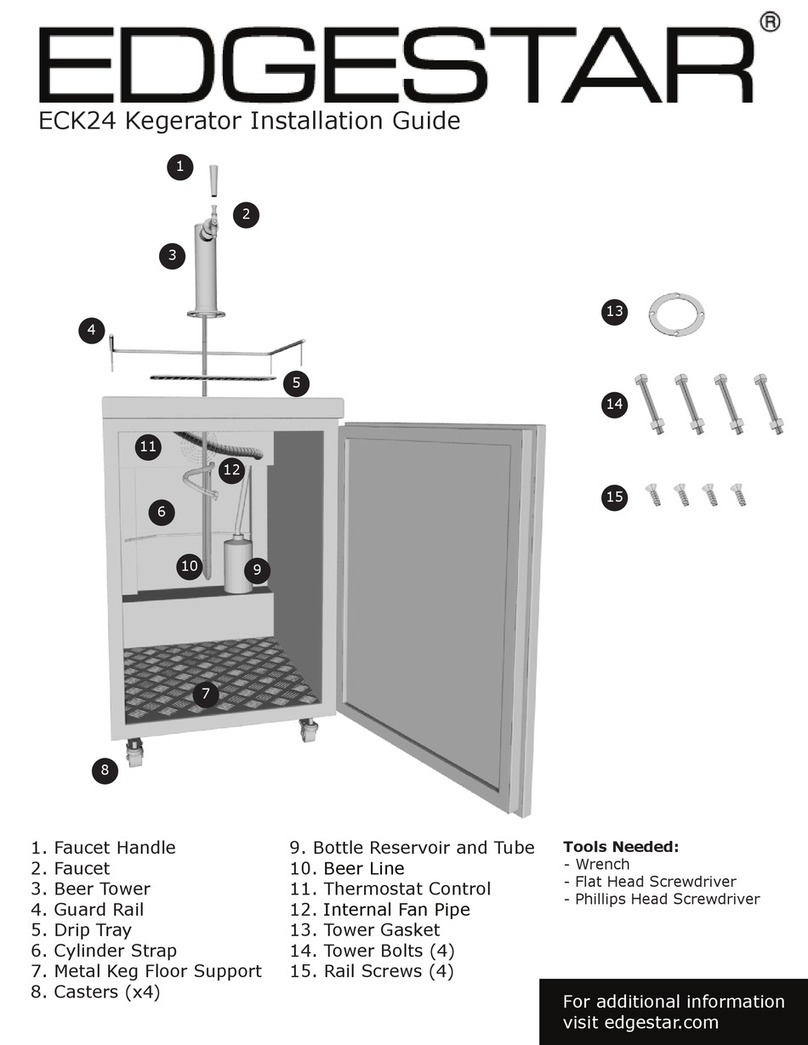

Items included ................................................................................................................................... 10

Single Tap Font Kit ......................................................................................................................... 10

Double Tap Font Kit ....................................................................................................................... 10

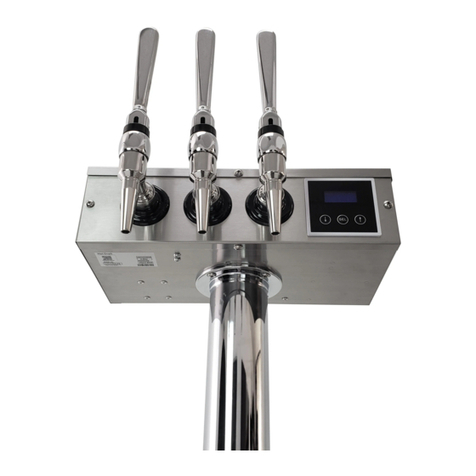

Triple tap font kit ...........................................................................................................................11

Quadruple tap font kit ...................................................................................................................11

Installation steps ............................................................................................................................... 12

Step 1. Preparation ........................................................................................................................12

Step 2. Install castor wheels........................................................................................................... 12

Step 3. Install chrome plated guard rail .........................................................................................12

Step 4. Attach the CO2 cylinder bracket (optional) ........................................................................12

Step 5. Fit the CO2cylinder to the cylinder bracket (if applicable)..................................................12

Step 6. Attach the regulator to the CO2cylinder ............................................................................12

Step 7. Attach the 4mm ID EVABarrier gas line to the regulator ....................................................12

Step 8. Feed the EVABarrier gas line into the fridge.......................................................................13

Step 9. Setting up the EVABarrier gas line for a single tap font. ....................................................14

Step 10. Setting up the EVABarrier gas line for a dual, triple or quadruple font............................. 14

Step 11. Assembling single, double and triple tap fonts................................................................. 15

Step 12. Assembling a quadruple font ...........................................................................................15

Step 13. Attach the tap to the duotight compatible short shank ................................................... 15

Step 14. Attach all disconnects to the keg(s)..................................................................................15

Step 15. IMPORTANT Perform a CO2leak/pressure test ................................................................15

Installation diagrams .........................................................................................................................17

Single Tap Series X Installation Diagrams .......................................................................................17

Double Tap Series X Installation Diagram.......................................................................................18