Keiser KMS800 User manual

Operating Manual

GB

1

2

3

4

5

6

7

8

2

1

3

5

6

8

7

4

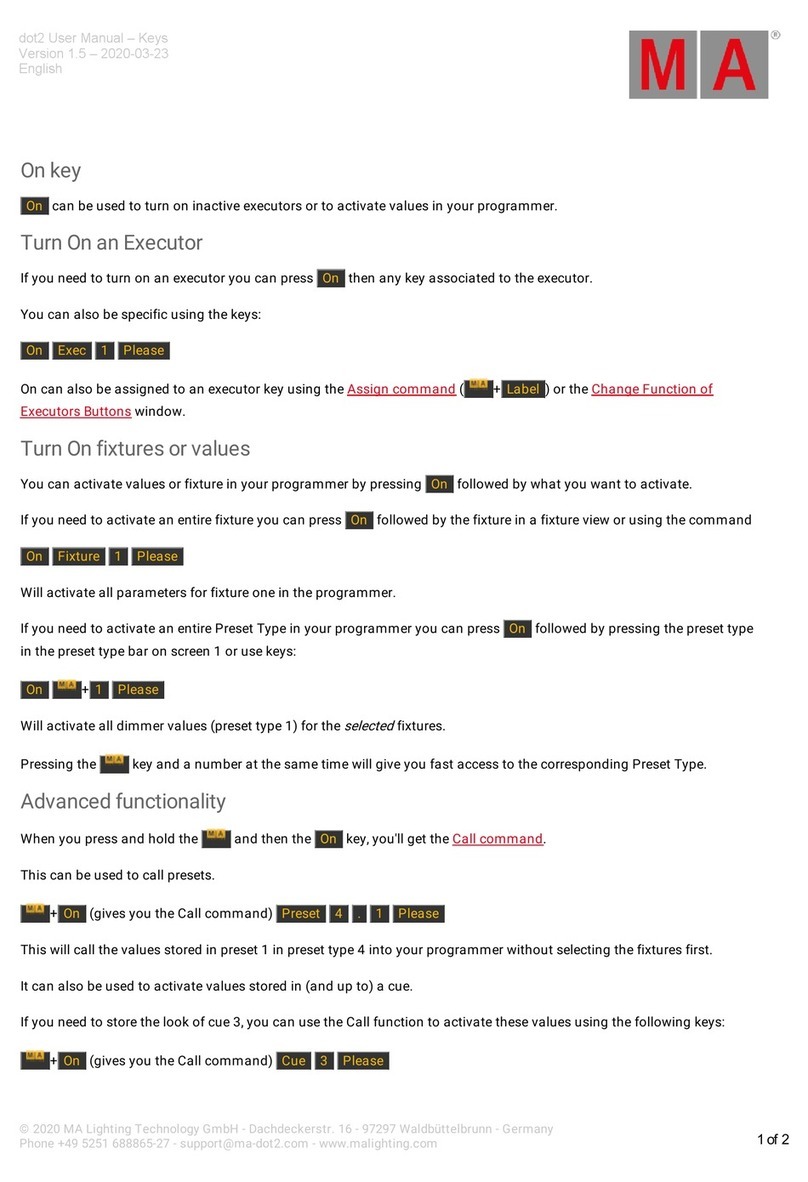

KMS800

KMD900

To o l f i t t i n gf

M 1 2 0 0 M X 1 8 0 0 D

M 1 4

1 2 0 m m

6kg

M27

140mm

8.5kg

1800w

Technical Data

Model KMS800 KMD900

Power 1800 W 1900 W

Frequency 50/60 Hz 50/60 Hz

No-Load Speed 1st Gear 150 - 300 rpm 150 – 300 rpm

2nd Gear 300 – 650 rpm 300 – 650 rpm

Maximum Tool Diameter 140 mm 140 mm

Weight 7.8 kg 8.5 kg

Mixing Quantity Up to 65 Litres Up to 90 Litres

Protection Class / II / II

1

Machine components

1 Release button for ON/OFF switch

2 ON/OFF switch

3 Gear selection switch

4 Handle frame

5 Handles

6 Ventilation slits

7 Neck of the machine

8 Mixing shaft

Not all the accessories illustrated or

described are included as standard delivery

WARNING:

Read all notes and instructions on safety.

Failure to observe any of the notes and instructions on safety

may result in an electric shock, fire and/or serious injury.

23

To be able to use the machine safely it is essential that you read the operating instructions

and the safety instructions thoroughly and comply with all of them. The machine is to be

used only by persons who have read the operating instructions and who are acquainted

with the occupational safety and accident prevention regulations in force in your country.

In addition, you must also comply with the general safety instructions also included with

the machine.

rating plate.

Do not use the device in any environment with potentially explosive atmosphere. Do not

below 21° C.

Take care to ensure that no liquid splashes against the motor housing and keep it away

from the rain – risk of electric shock!

Never clean the machine with water – risk of electric shock!

Do not wind cables or leads around any parts of your body.

Do not use the machine with a damaged cable. Do not touch the cable and pull out the

power plug immediately. There is an increased risk of electric shock from damaged cables.

If the mains power cable has to be replaced (because of damage or similar), ensure that it is

replaced by an authorized representative of the manufacturer (electrician) in order to avoid

any risk to safety.

sure you have a secure footing.

Before starting up, check that the mixing rod is securely attached and rotates without a hitch.

Start up and run down the machine in the mixing container only. Ensure that the mixing

Do not reach into the mixing container with your hands or insert any other objects into it

while mixing is in progress. Risk of crushing!

Wait until the machine or tool comes to a complete standstill. Rotating tools can snag and

cause injuries or damage.

Use ear protection!

We recommend that you wear work gloves and protective goggles when using the mixer.

To protect yourself from harmful dust while mixing, wear a dust mask. Use a dust extractor

wherever possible.

Always connect machines via a residual current device (RCD) with a rated residual current

of 30 mA or less

Read and observe the operating instructions for the

machine before you start it up!

Always wear protective goggles and ear protection

while working.

It is advisable to wear a dust mask whenever working

with materials which generate large amounts of dust.

Always wear protective gloves while working.

Safety Precautions

45

Operation

Check that the power supply shown on the rating plate is the same as the mains power supply.

Always hold the machine with both hands. Press the starting lockout button (1).

Press the ON/OFF switch (2).

For safety reasons, the ON/OFF switch cannot be locked! Always work with the ON/ OFF switch

fully pressed.

To stop working, release the ON/OFF switch.

Machines with 2-speed gear units have two maximum speeds available (First gear: Slow and

Second gear: Fast).

To change from one gear to the other, turn the gear selection lever. Only ever actuate it when

the machine is at a standstill.

Always reduce the speed when submerging the mixing tool in the mixing material or lifting it

out. Once the mixing tool is fully submerged, increase the speed again to ensure that the

motor is adequately cooled.

During mixing you should guide the machine around the mixing container. Continue mixing

until all of the mixing material is completely mixed. Please follow the processing instructions

of the manufacturer of the material.

The greater the viscosity of the material, the greater the impact of the torque forces on the

machine, so you should be prepared for this when you carry out your work.

If the mixing tool comes into contact with a surface (e.g. the bottom of the tub) while running,

it may kick back.

Set the machine down resting on the guard handle after you have nished your mixing work.

Proper use

The machine is designed for mixing liquid and powder-based building products such as

paints, mortar, adhesives, plaster and similar substances. Use the right mixing tool for the

consistency of the material and the quantity to be mixed.

Please refer to the information in the technical data when choosing the size of mixing tool

(diameter/ mixing action). If the wrong mixing action or mixing tool diameter is selected,

this may cause the machine/gear unit to become overloaded and lead to damage as a result.

Please remember that a mixing tool with a mixing action from the top down puts a greater

strain on the electrical tool than one with the reverse mixing action.

This electrical tool is not designed for use in continuous operation.

Given the high torque levels generated by the machine, it must not be used as a power drill.

The machine must not be used for the preparation of foodstus.

The machine is not suitable for mixing materials containing graphite dust, brine or slurry.

Mixing of these materials or substances may damage the machine beyond repair.

Assembly Operation

Always pull the power plug out of the socket outlet before carrying out any work on the

machine.

Fitting the mixing tool / tool change-over: Screw the mixing tool with a size M14 male

thread into the M14 adapter on the mixing shaft. The mixing tool tightens itself during

operation.

To release the mixing tool you will need one SW 22 and one SW 24 open-ended wrench.

Place the one open-ended wrench on the adapter and the other on the hexagonal holding

xture and turn them both in opposite directions to one another until the mixing tool is

released

67

Care and maintenance

Before you carry out any operations on the machine, and especially when changing the

mixing tool, always pull out the power plug rst.

Clean the machine and the mixing tool immediately after use.

Take the mixing tool out of the coupling after you have nished your work.

Grease the M14/M27 mount of the coupling at regular intervals with suitable grease.

Keep the ventilation slits clean and clear at all times so that the machine can be properly

cooled. Blocked ventilation slits will lead to irreparable damage to the machine.

Make sure that the ON/OFF switch moves and releases smoothly at all times.

The machine is equipped with self-deactivating carbon brushes. This means that the

machine will shut itself down once a certain level of wear is reached. The carbon brushes can

be replaced by the authorized customer service centre or by the KEISERtools Service centre.

Have repairs carried out only by an approved workshop or by your KEISERtools Service. Only

use original KEISERtools accessories and replacement parts.

Disposal

The device, accessories and packaging should all be consigned for environment-friendly

recycling. Electrical tools which have come to the end of their service lives must be made

unusable by removing the mains power cable.

For EU countries only:

Do not dispose of electrical tools with household waste.

In accordance with EU Directive 2002/96/ EC concerned with used electrical and electronic

equipment and the incorporation of the requirements of the directive in national legislation,

unusable electrical equipment must be collected separately and consigned for environ-

ment-friendly recycling.

Warranty

The manufacturer provides a warranty within the framework of his terms and conditions of

delivery in accordance with the requirements of statutory/ country-specic provisions. Should

you need to make a claim under the warranty, please provide us with your invoice or delivery

note.

On no account will any warranty claims be accepted if any repairs are carried out by third

parties. In the event of any irregularities, please send the machine to us. Complaints can only

be accepted if the device is sent to the KEISERtools Service centre undismantled.

The warranty does not apply to damages caused by normal wear, overloading, improper

handling, unsuitable accessories or inadequate maintenance.

Any structural or functional modications to the machine which are made without our agree-

ment shall render the warranty and the Declaration of Conformity null and void.

Subject to change.

89

KMS800

No.

Description

No.

Description

1

Right Handle

33

The rotor

2

Left Handle

34

M insulation gasket

3

Screw ST3.9X20

35

Bearing 608 Z

4

Clamp

36

Needle bearing HK0810

5

Screw ST3.5X16

37

The second active gear shaft

6

Capacitance

38

Hemicycle key 2.5X3.7X10

7

Round inductance

39

Motor gear

8

The inductance

40

Safety ring

¢

10

9

Circuitry board

41

Bearing 698 Z

10

Sleeve

42

The third active gear shaft

11

Cable

43

Parallel key 4X4X45

12

Switch

44

Spindle double gear

13

Steel frame

45

Flat washer

¢

16*8*0.8

14

Screw M8X12

46

Pivot

¢

6*106

15

Cord

47

Coulisse

16

Sleeve

(

Big

)

48

Partial core + eccentric wheel core

17

Safety ring

¢

47

49

Ball

¢

4

18

Dust cover

50

Spring

¢

0.5*

¢

3.9*L12

19

Screw M5X20

51

Lever

20

Spring washer

¢

5

52

Screw ST3X16

21

Bearing cover

53

Screw ST5X65

22

Pin 4*14

54

Brush cap

23

Spindle

55

Carbon brush 6.5*15*18

24

Hemicycle key 4X5X12

56

Brush holder

25

Bearing 6204 Z

57

Screw M5X25

26

Safety ring

¢

20

58

Air guide shim

27

Spindle gear

59

The stator (including the brush ring)

28

Safety ring

¢

15

60

Chassis

29

Bearing 6000 Z

61

Clamp

30

Gear box

62

Constant power board

31

Sealring

¢

28*1.9

63

Circuit board seats

32

Bearing 6001 2RS

64

Rear cover

10 11

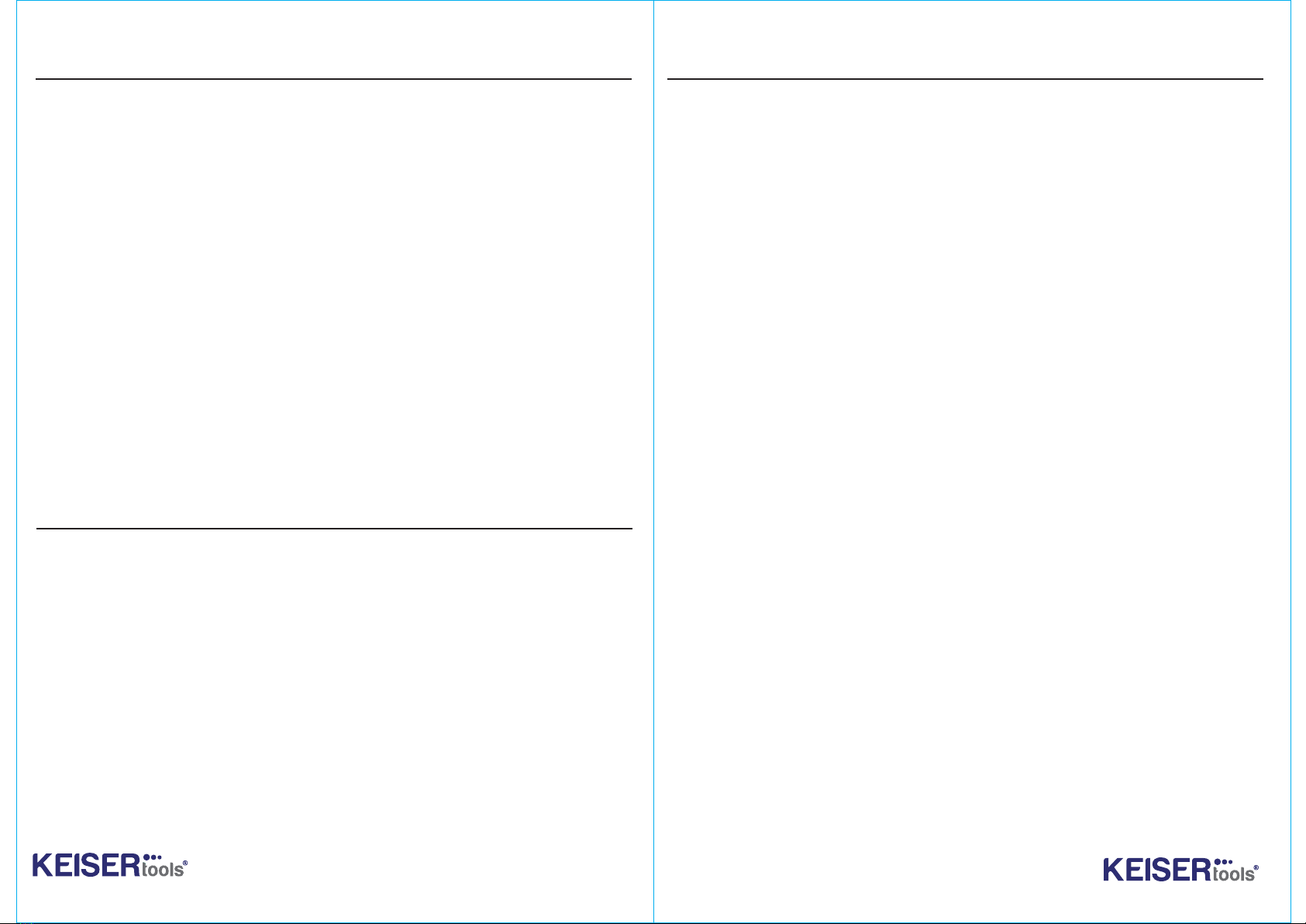

KMD900

No.

Description

No.

Description

1

Right Handle

37

Safety ring

¢

9

2

Left Handle

38

The reversing shaft

3

Screw ST3.9X20

39

Safety ring

¢

26

4

Clamp

40

Reversing the tooth

5

Screw ST3.5X16

41

Bearing 6000 Z

6

Capacitance

42

Needle bearing HK0810

7

Round inductance

43

The second active gear shaft

8

The inductance

44

Hemicycle key 2.5X3.7X10

9

Circuitry board

45

Motor gear

10

Sleeve

46

Safety ring

¢

10

11

Cable

47

Bearing 698 Z

12

Switch

48

The third active gear shaft

13

Steel frame

49

Parallel key 4X4X45

14

Screw M8X12

50

Spindle double gear

15

Cord

51

Flat washer

¢

16*8*0.8

16

Sleeve

(

Big

)

52

Needle bearing HK0808

17

Threaded sleeve

53

Pivot

¢

6*89

18

Safety ring

¢

40

54

Coulisse

19

Dust cover

55

Partial core + eccentric wheel core

20

Bearing 6203 Z

56

Air guide shim

21

Screw M5X20

57

The stator (including the brush ring)

22

Spring washer

¢

5

58

Chassis

23

Bearing cover

59

Clamp

24

Spindle

60

Constant power board

25

Hemicycle key 3X3X10

61

Ball

¢

4

26

Bearing 6002 Z

62

Spring

¢

0.5*

¢

3.9*L12

27

Safety ring

¢

17

63

Lever

28

Spindle gear

64

Screw ST3X16

29

Safety ring

¢

12

65

Screw ST5X65

30

Gear box

66

Brush cap

31

Seal ring

¢

28*1.9

67

Carbon brush 6.5*15*18

32

Bearing 6001 2RS

68

Brush holder

33

The rotor

69

Screw M5X25

34

M insulation gasket

70

Circuit board seats

35

Bearing 608 Z

71

Rear cover

36

Pin 4*14

This manual suits for next models

1

Table of contents