4

Keller minimal windows®

Keller minimal windows®4+ 02

(2)

75

±100

150

60 21 60

135

141

100 21 60

135

241

BB

60

a

b

On-site installation | 997-000120 | 07-2021

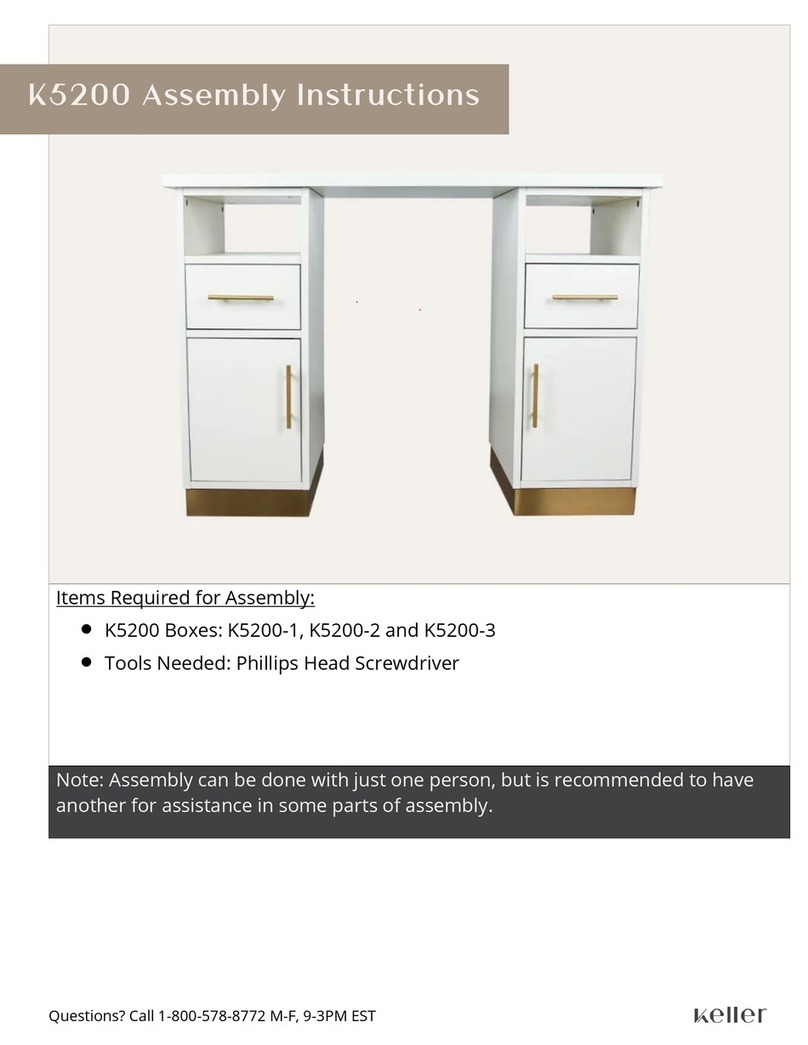

2.1 Standard substructure

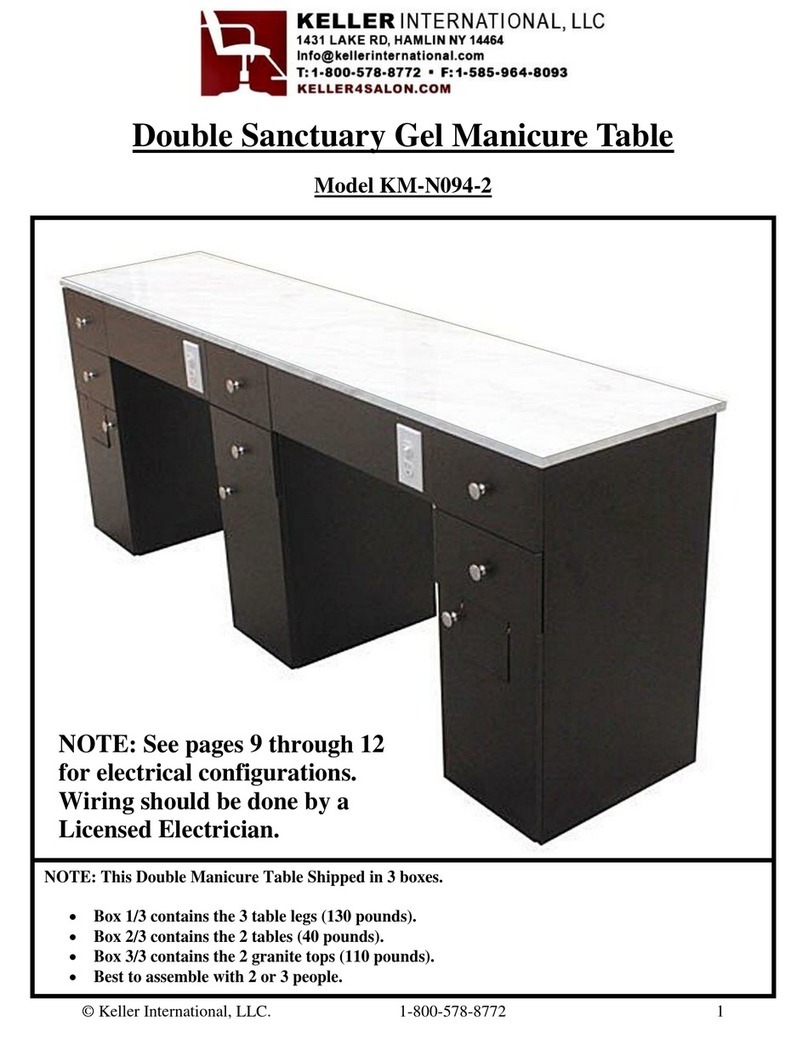

2.2 Substructure for big / heavy leafs

OKFF 0.0

Required minimum installation depth for flush

floor connection in new buildings: 141mm

(excl. levelling)

Levelling max. 10mm for smallest dimension

OKRB -150.0

Sealing foil (EPDM)

OKFF 0.0

Required minimum installation depth for flush

floor connection in new buildings: 241mm

(excl. levelling)

OKRB -260.0

Sealing foil (EPDM)

Levelling max. 20mm for smallest dimension

Drainage base frame (PVC-U)

Drainage

Substructure

Keller minimal windows®basestone

Sealing foil EPDM)

Drainage base frame (PVC-U)

Drainage

Substructure

Keller minimal windows®basestone

Sealing foil (EPDM)

(1) Rectangular tube [150x100x6mm]

(1) Angular profile [150x75x10mm]

(inside & outside)

(every 800 to 1000 mm)

2. Drainage base preparation

Additional substructure: (1) An additional substructure is always provided on site and determined in consultation with the Keller technical team.

(2) On-site fixing: screws or welding

2.3 Allowable bending of the outer frame

During assembly During operation

a : ± 0.5 mm / m a : ± 1 mm / m

b : ± 1 mm b : + 2 / - 5 mm