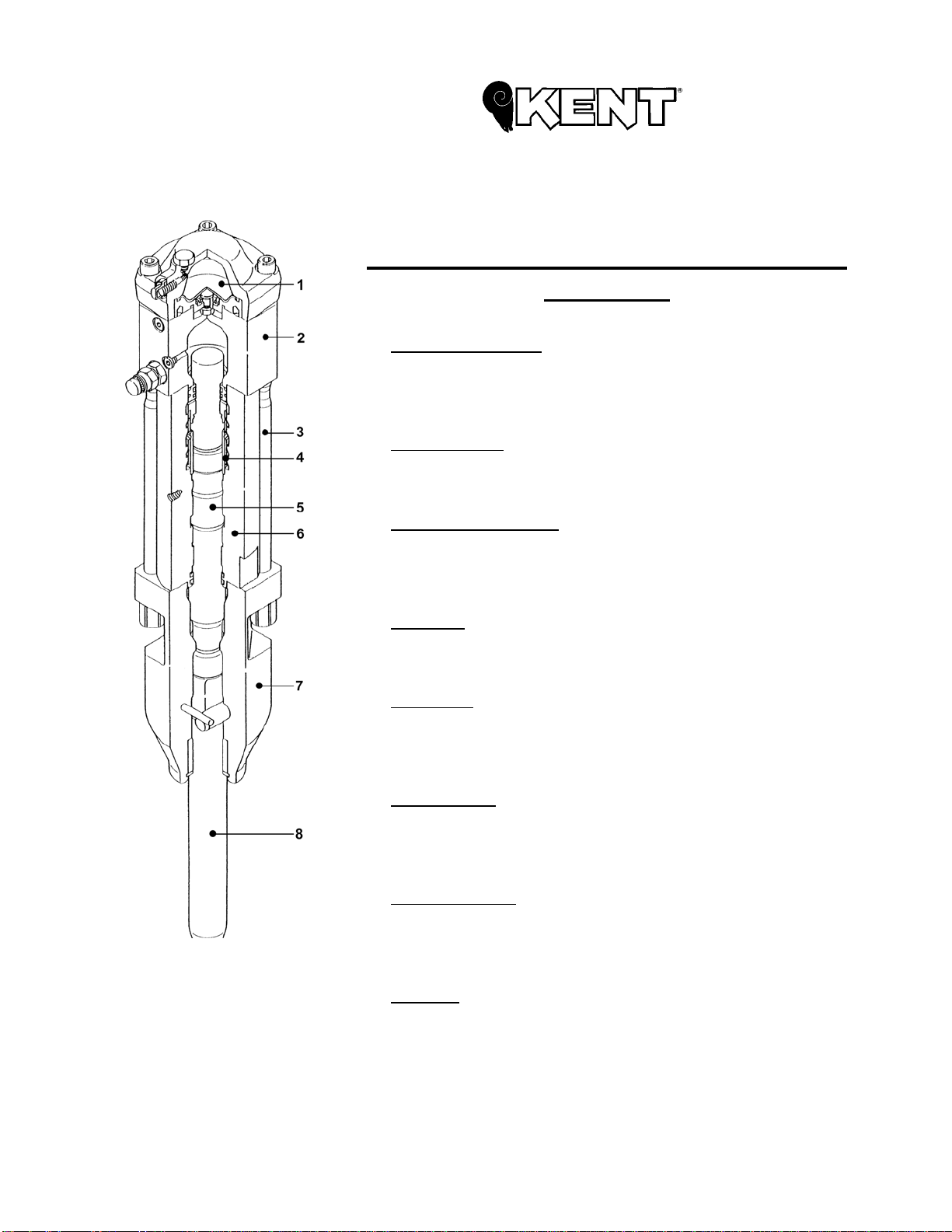

NOV/2005 Section A – Page #5

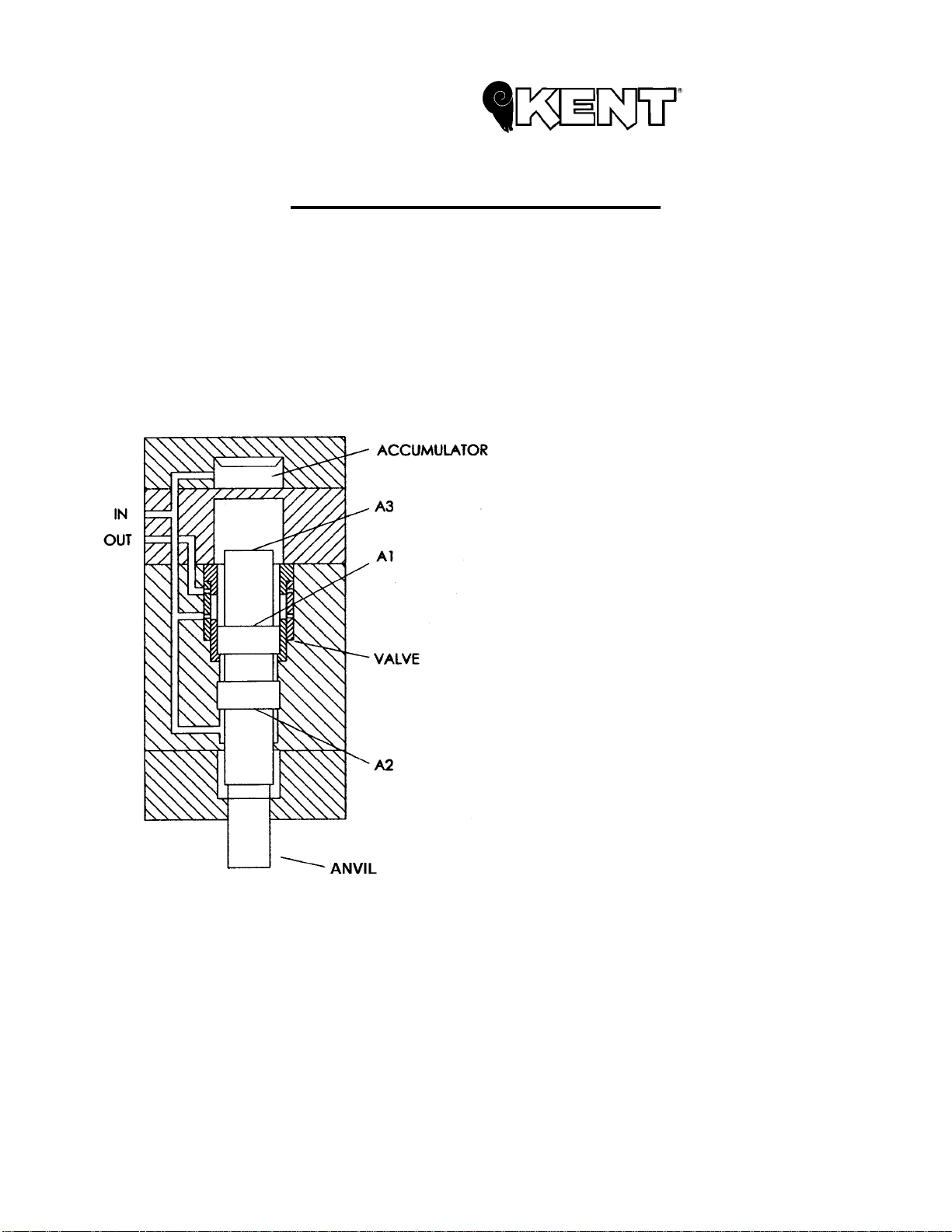

PRINCIPLE OF OPERATION

The impact energy is a product of the force acting on piston and the length of its stroke. The

piston is powered by the direct action of the hydraulic oil pressure and flow to the hammer.

The following illustration is a simplified sketch of the hydraulic oil porting of the hammer. Area

(A1) of the piston is larger than area (A2) of the piston. Area (A1) is alternately connected to the

pressure (IN) or the return (OUT) lines of the hammer by the valve. Area (A2) is always connected

to the pressure (IN) line. Area (A3) is an unpressurized chamber which allows for the free

movement of the piston.

The piston rises when area (A1) is

connected to the return (OUT) line. The oil

pressure on area (A2) is greater than the

oil pressure acting on area [A1], driving the

piston upward.

At the end of the return stroke, the

valve shifts, diverting the oil to area (A1) of

the piston. The oil pressure drives the

piston downward striking the working steel.

The kinetic energy of the piston at this

point is transferred to the working steel.

The working steel is then driven into the

material to be broken. At this point, the

valve shifts back to its original position,

causing the cycle to repeat.

To maintain continuous oil flow during

the valve shift, a bladder-type accumulator

is utilized. The accumulator acts as a

variable size reservoir for the oil, allowing

for continuous oil flow during the time the

piston is changing direction. This reduces

the pulsations in the hydraulic system.