2

•Turn on the pump/power switch, the pump will start circulating the fuel rail

cleaning fuel

•Check for leaks on vehicle’s return and supply connectors

•Set the pressure between 6 – 10 psi with the flow valve on the machine

(+ to increase - to decrease)

•Set timer to 20 min

•Turn on alarm switch

•If desired Hook up Induction Adapters and fill the tank with the aluminum cap

marked Air Induction Cleaner Only

•Start the engine leave at idle (NOTE: If the engine fails to start, bleeding the

fuel system may be necessary) When 10 – 15 minutes are up the cleaning fuel

should almost be depleted.

•When the complete service is finished turn vehicle off

•Turn pump switch off,

•Disconnect the power cord from the battery

•Uncouple the quick connectors from the hose adapters

•Disconnect hose adapters from Vehicles supply and return lines

•Reconnect the vehicle’s supply and return lines

•Start the vehicle, Check for leaks

Cummins 6.7 Liter 2500 and 3500

1. Remove Plastic Engine Cover

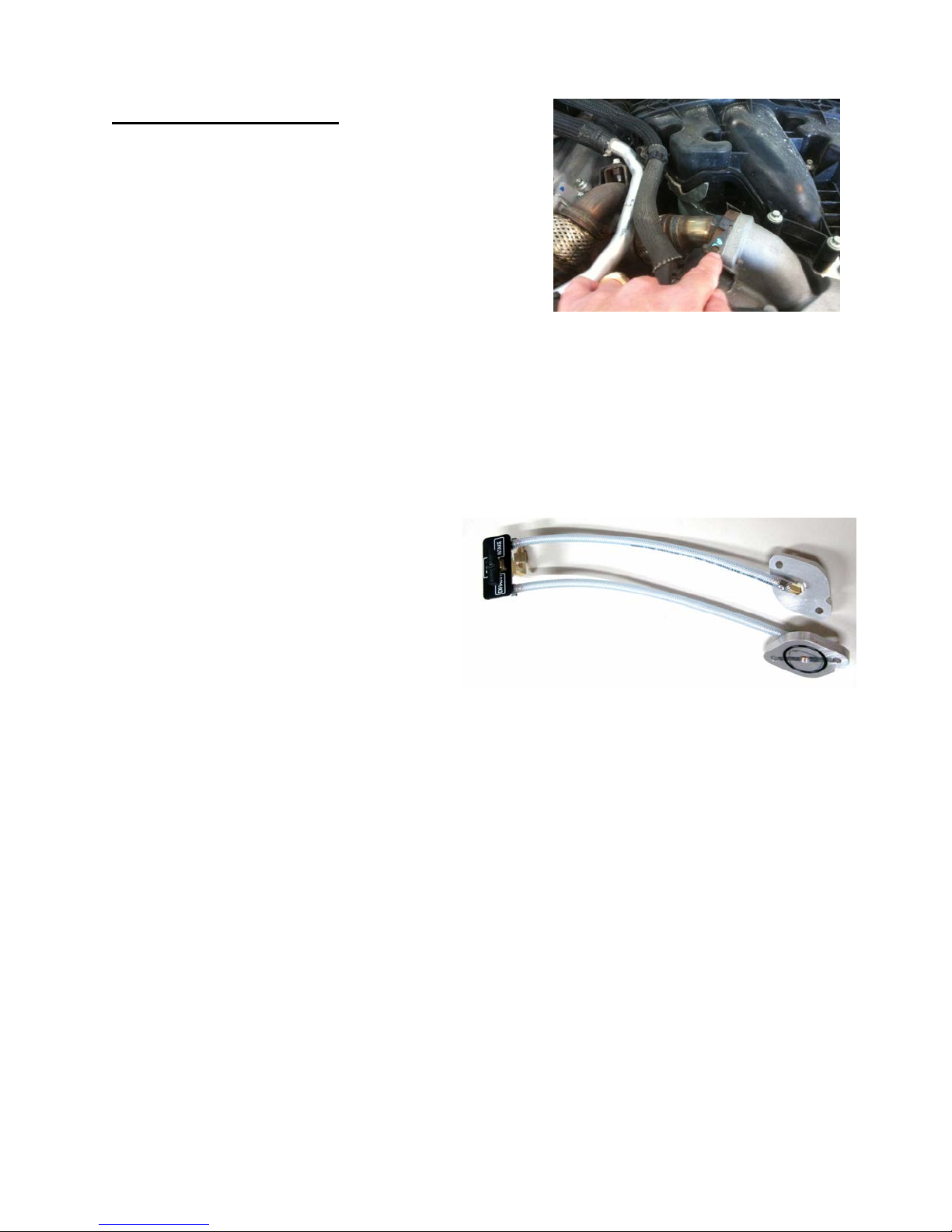

2. Remove the exhaust pipe from the EGR Valve.

3. Attach adapter DFS 910-17 to the EGR exhaust pipe with clamp.

4. Attach the hose end of the DFS910-17 to the EGR and tighten clamp. Attach DFS

910-5 to DFS 910-17 make sure air valve is closed.

5. Remove EGR electronic solenoid and attach DFS 910-9 to where the solenoid was

attached.

6. Start vehicle engine. Set air Pressure on Atomizer Tank to 80 psi.

7. Open EGR using the DFS 910-9

8. On the DFS910-5Turn on the Air. Turn the DFS 910-17 to the Intake side. Turn

Atomizer valve to ON position on the machine.

9. After 1 lit/qt turn atomizer valve off. Switch the DFS 910-17 to the Exhaust side.

10. Turn Atomizer to on position and turn air valve on DFS 910-5 to on. Run until

atomizer fluid is empty.

11. Turn Atomizer valve of and Fill the Atomizer Tank with 1 lit/qt Rinse Solution and

repeat the above steps.

12. Turn Atomizer Valve and Air valve on DFS 910-5 to OFF position. Turn Vehicle off,

turn fuel pump off on the machine. Disconnect fuel hoses, adapters remove

DFS 910-4 and reattach the EGR exhaust pipe and fuel lines.

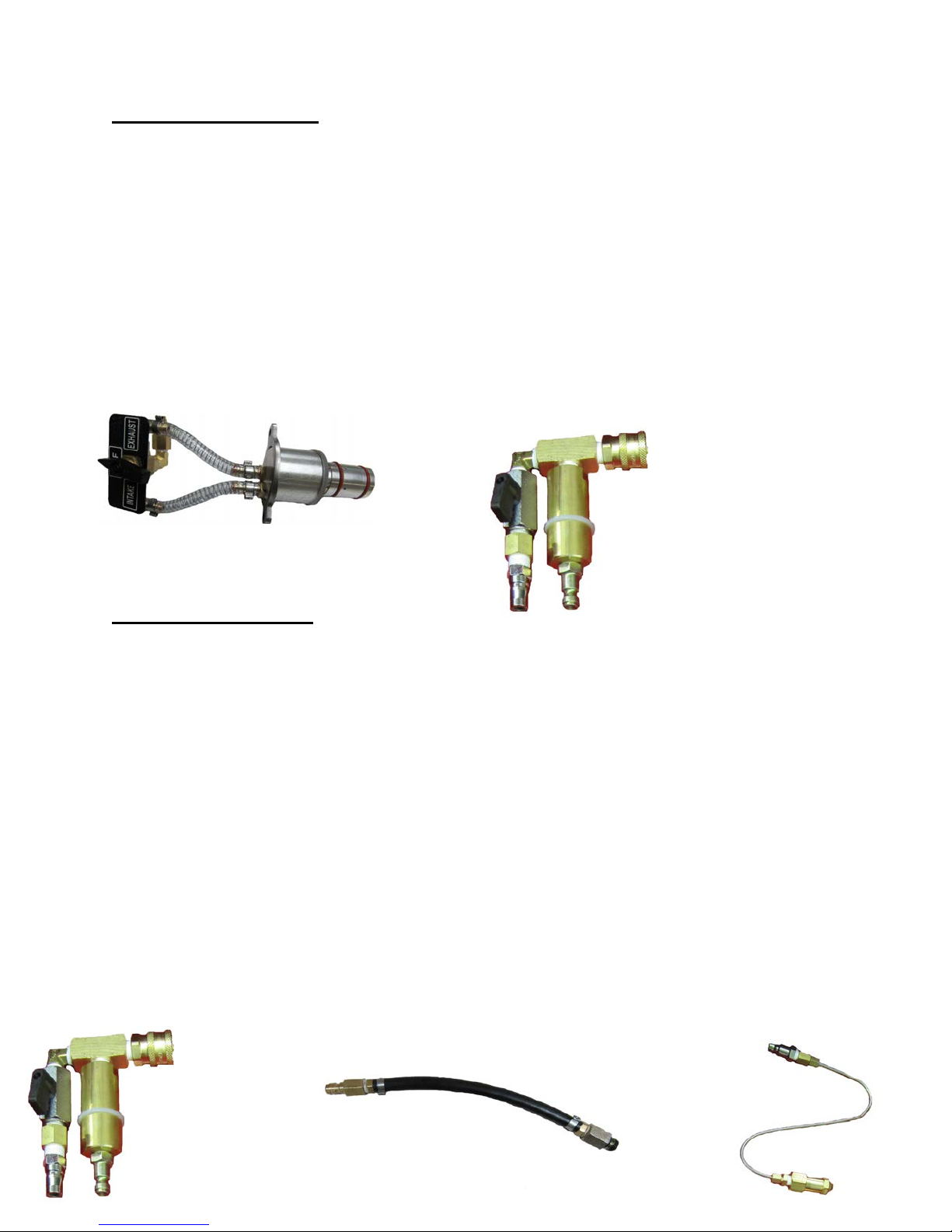

DFS 910-17

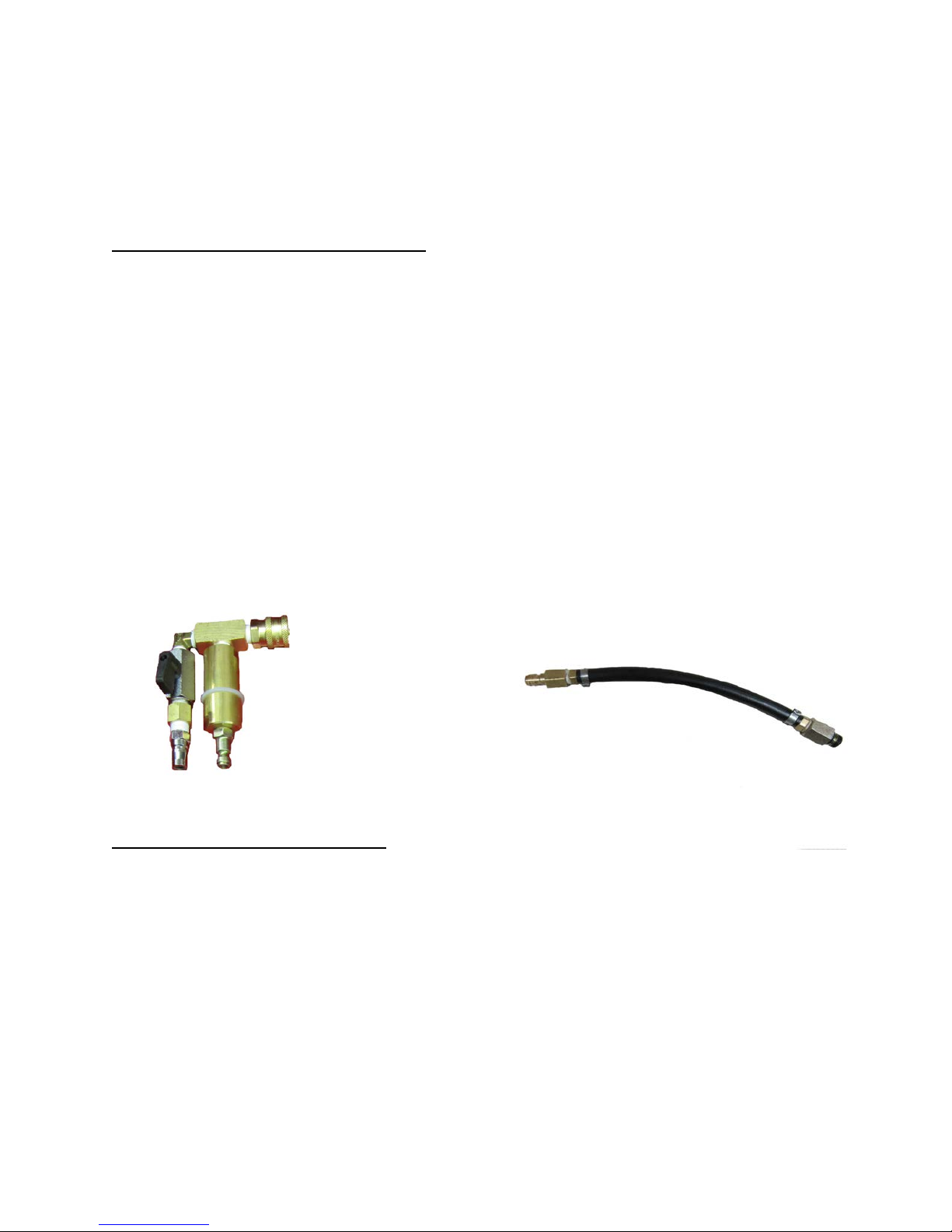

DFS 910-5