KKP_V40-IA-e-1811 2

GB

Version 1.103/2018

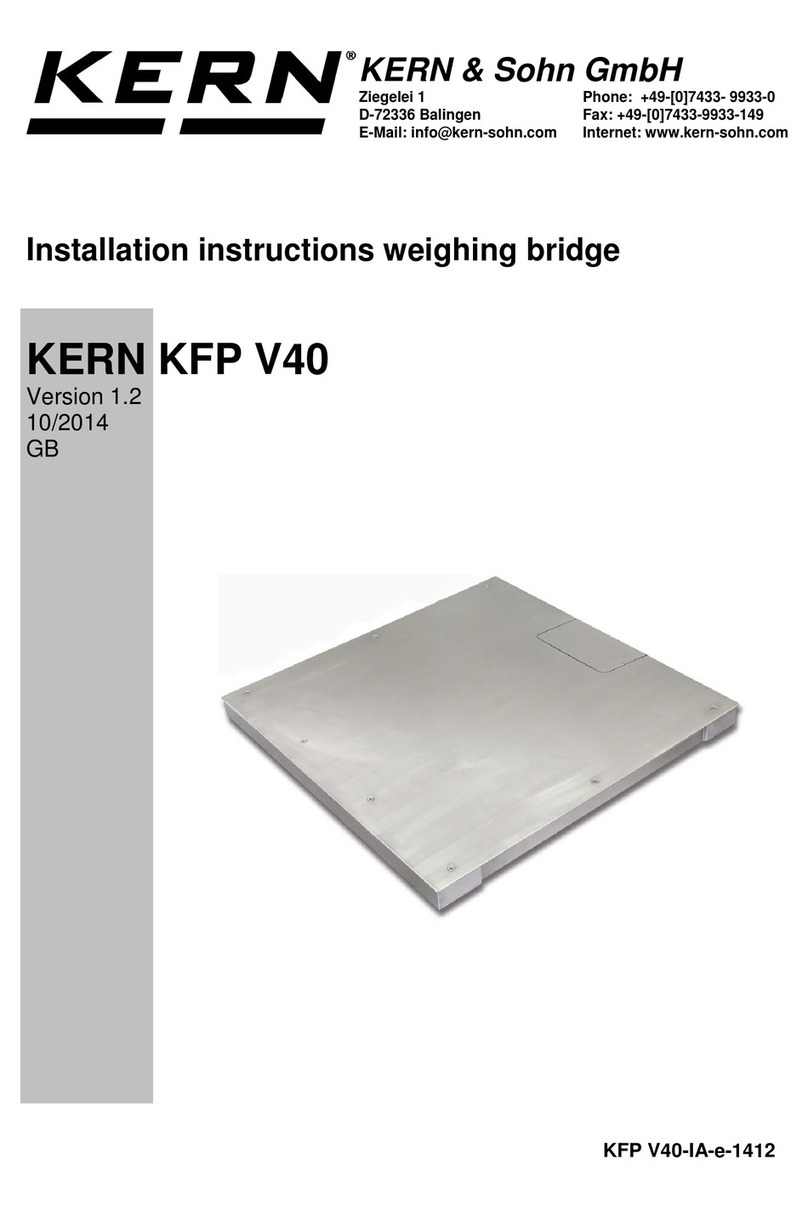

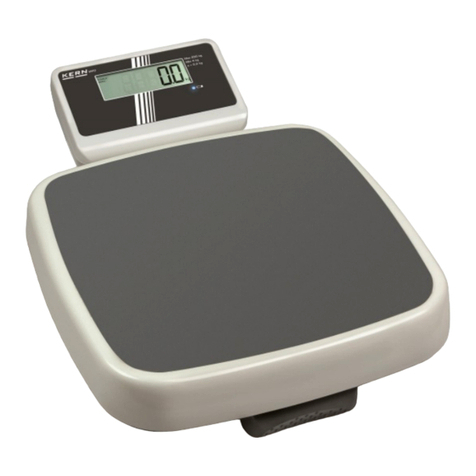

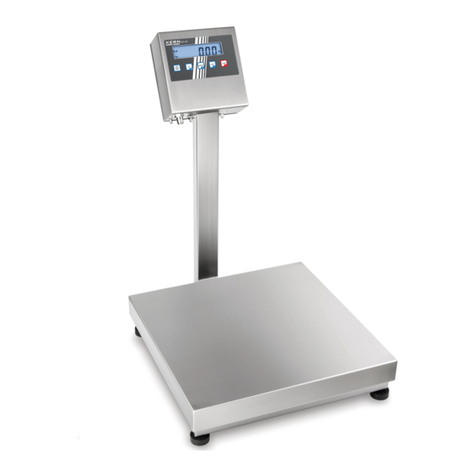

Installation instructions weighing bridge

Contents

1General hints.................................................................................................. 3

2Technical data................................................................................................ 3

3Basic instructions.......................................................................................... 3

3.1 Documentation ........................................................................................................................... 3

3.2 Proper use.................................................................................................................................. 3

3.3 Improper Use.............................................................................................................................. 4

3.4 Warranty..................................................................................................................................... 4

3.5 Monitoring of Test Resources .................................................................................................... 4

4Basic Safety Precautions.............................................................................. 5

4.1 Pay attention to the instructions in the Operation Manual.......................................................... 5

4.2 Personnel training....................................................................................................................... 5

5Transport and storage................................................................................... 5

5.1 Testing upon acceptance ........................................................................................................... 5

5.2 Packaging / return transport....................................................................................................... 5

6Unpacking, Setup and Commissioning ....................................................... 6

6.1 Installation Site, Location of Use................................................................................................ 6

6.2 Unpacking, Scope of delivery..................................................................................................... 7

6.3 Assembly, levelling..................................................................................................................... 8

6.5 Cleaning ..................................................................................................................................... 9

6.6 Connecting a display unit ........................................................................................................... 9

7Operation...................................................................................................... 10

7.1 Operation limits......................................................................................................................... 11

7.2 Operation with access ramps................................................................................................... 12

7.3 Load/unload weighing bridge ................................................................................................... 12

8Servicing, maintenance, disposal .............................................................. 13

8.1 Daily check ............................................................................................................................... 13

8.2 Cleaning ................................................................................................................................... 13

8.3 Servicing, maintenance............................................................................................................ 13

8.4 Disposal.................................................................................................................................... 13

8.5 Instant help............................................................................................................................... 14

9Service documentation ............................................................................... 15

9.1 Verification data and tolerances............................................................................................... 15

9.2 Check and adjustment of the corner load................................................................................. 16

10 Overload settings......................................................................................... 17