Kersten K 820 Technical reference manual

Instruction and Parts Manual

K 820

Front sweeping machine

Part no E00002-1 Pre Machine Number 50144 Copyright Kersten (UK) Ltd © 2008 Compiled 19/01/09

UK Kersten Maschinenvertriebs

GmbH

D - 46459 Rees, Empeler Straße

93-95

www.kersten-maschinen.de

Tel.: 028 51 / 92 34 0

Fax: 028 51 / 92 34 44

Kersten (UK) Ltd

Progress House, 39 Boulton Road

Reading, Berkshire RG2 0NH

Phone: 0118 986 9253

Email: [email protected]

2

3

CONTENTS

Page

1 About this manual 4

1.1 Product Identification 4

1.2 Before start-up 4

1.3 Intended use 5

2 Safety Precautions 5

2.1 General safety and accident prevention instructions 6

2.2 Transporting 6

2.3 Safety 7

3 Basic rules 8

3.1 Before starting up 8

3.2 Repair work 8

3.3 Basic maintenance 8

4 Disposal 9

5 Warranty 9

6 Specification 10

7 Assembly 11

7.1 Assembly Dirt Collector 11

7.2 Container - Adjustment 11

7.3 Assembly – Side Broom 12

7.4 Adjustment – Removal of Side Broom 13

8 Operation 14

9 Operating Instructions 15

10 Collector - Adjustment 15

10.1 Side Broom Adjustment 15

11 Maintenance 16

11.1 General Information 16

11.2 Maintenance 16

11.3 Daily Maintenance 16

11.4 Maintenance after 20 and 100 use or longer 16

11.5 Installinf a replacement sweeping brush 17

12 Disposal 18

13 Warranty 18

15 Certificate of conformity 19

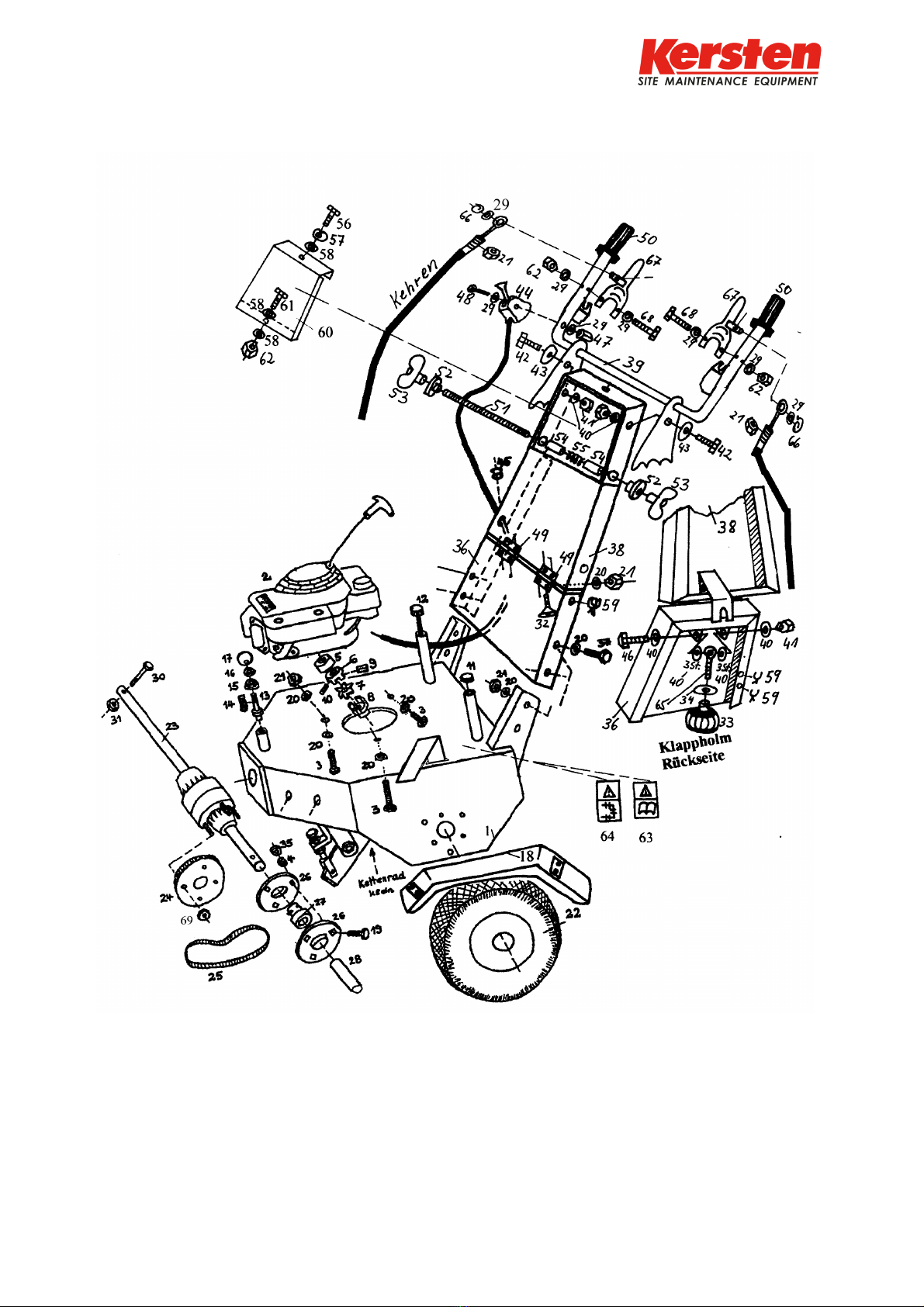

Parts lists 20-23

4

1 About this manual

Dear Customer,

We thank you for the purchase of this machine or attachment and having

confidence in our equipment.

Before using this machine please read this instruction manual carefully.

Keep this manual to hand as it contains important information and

instructions.

The machine or the attachment is subject technical progress.

All Information, illustrations and technical data corresponds to the newest

model at the time of the publication.

Changes due to technical progress are reserved by the manufacturer at any

time.

1.1 Product Identification

Always quote model number and serial number when ordering spare parts.

The identification plate may be found on the main chassis of all machines.

1.2 Before start up

We are not liable for any substantial accident and/or damage.

Before you drive this machine or start the engine of the Kersten machine that

you are handling, we ask that you urgently to make yourself familiar with this

manual and the operation of the machine.

●This symbol indicates important safety information!

●Read all safety references on the following pages!

●Read the operating instructions before start-up!

●Use this manual in conjunction with the power unit manual!

●Pass all safety instructions onto other users!

Typ

Id-Nr

Model Number

Serial Number

KERSTEN

Maschinenvertriebs GmbH

D46459 REES

5

1.3 Intended use

●The machine is a hydraulically propelled 2 wheel tractor exclusively

intended for professional employment in the management of land,

forestry, amenity and landscape conservation and for sole use with

Kersten attachments. (Also see individual attachment instructions.)

●Use going beyond that described is not considered as intended.

Therefore the manufacturer is not responsible for any resulting damage

or harm and the operator alone is responsible for the risk.

●Compliance with and adherence to the operating, maintenance and repair

as prescribed by the manufacturer in this manual must be considered

essential elements of intended use.

●The machine may only be operated repaired and serviced by persons

familiar with the machine, this manual and all relevant safety features

and dangers.

●The relevant rules for the prevention of accidents as well as other safety-

relevant rules according to the health and safety at work act must be

considered as part of the operating procedure.

●The manufacturer is not liable for any accidents or damage resulting

from modifications or alterations carried out on the machine without the

express written permission of the manufacturer.

2Safety Precautions

It is important to note that not all possibilities can be covered within this

manual.

The manual assumes that the operator has a general awareness for

Health and Safety to be appointed an operator in the first place.

This Kersten machine has been designed, so far as is reasonably

practical,

So that it will not endanger the safety of the operator or anyone else if

the machine is used and maintained according to the instructions stated

in this manual which have been compiled following research and

experience of the manufacturers.

2.1 General safety and accident prevention instructions:

6

●Consider all additional valid general operating instructions and health and

safety regulations

●This machine should not be operated by any person under the age of 16.

●This machine may be subject to regulations when used on the public

highway

●Before starting operating this machine you should be familiar with all

controls and their functions. Familiarization should not be carried out

during operation.

●The user is responsible for operating the unit in the work area.

●Standing in the danger area of the machine is forbidden!

●Look out for any children or animals in the work area.

●Operators are advised to wear clothing that is close fitting with stout

footwear. Loose fitted clothes or casual footwear increase risk of accident

●All controls, engine and functions must be cleaned regularly.

●Do not leave the engine running in an enclosed area.

●Whenever handling fuel there is an increased risk of fire. Never refill

near a naked flame or sparks, do not smoke whilst refilling the fuel tank.

Before refuelling, turn the engine off, allow to cool down and take

ignition keys out (if available).

●Keep machine clean to reduce the risk of fire

●When starting the engine all drives must be switched off

●Never leave the operator console while driving

●Never adjust the handlebar while engine is running

●Never leave the machine whilst engine is running.

●Close the fuel valve when machine is not in use.

●Apply parking brake (where fitted), when leaving, and minimize

unauthorized use!

●Never leave the equipment unsupervised, when the engine is running.

2.2 Transporting

When transporting this unit ensure all possible power is isolated disengaged and

disabled.

Apply parking brake where fitted.

Secure the machine by use of bindings any transporting vehicle.

Only transport on vehicles designed for the use of transporting this type of

equipment.

Safety

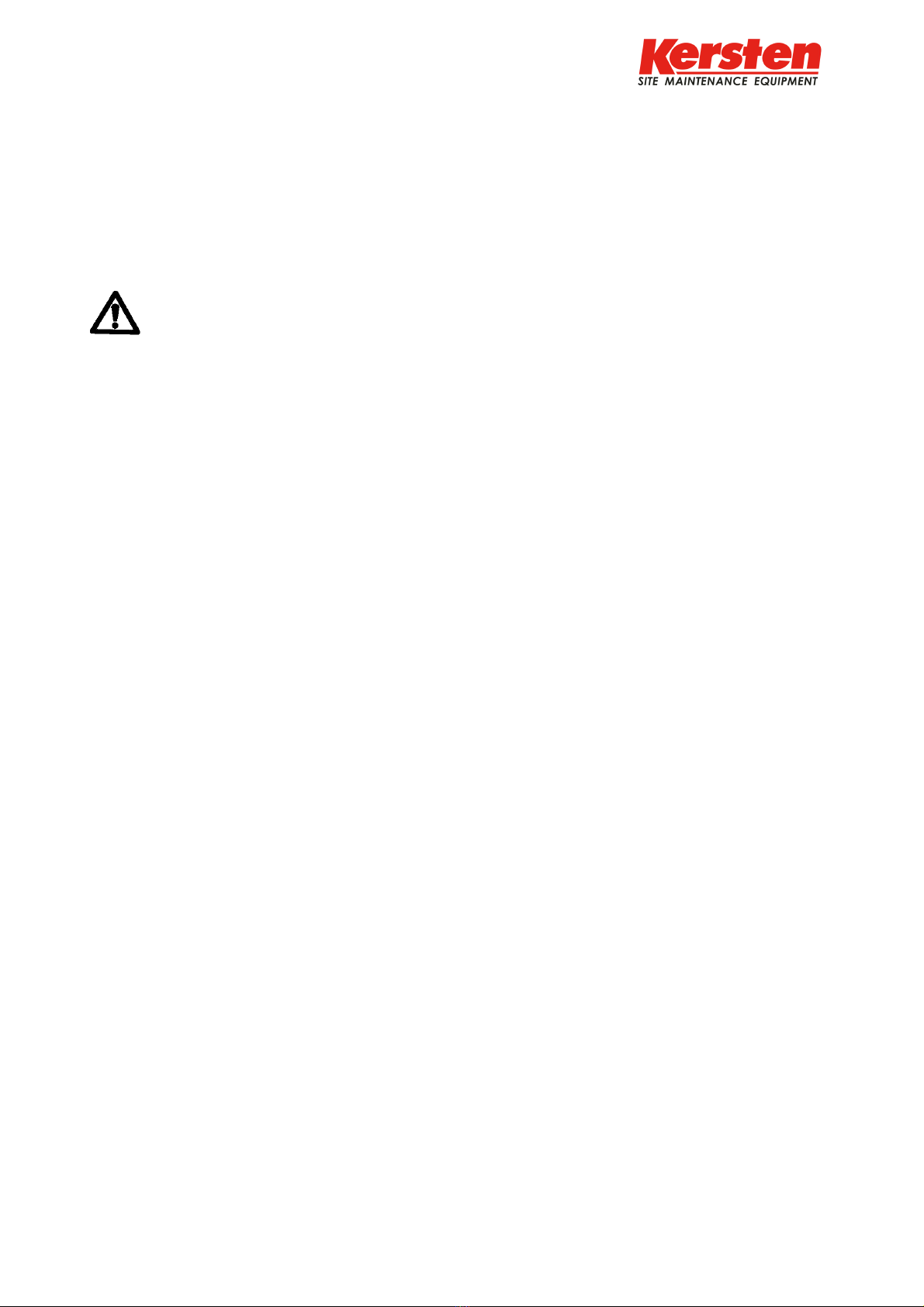

Attention! This machine is equipped with warning symbols (safety decals).

Be aware of your safety at all times when operating a machine.

Real security means that you are familiar with all safety decals.

7

These decals indicate types and areas of endangerment and in particular the

safety measure which should be taken.

Always remain alert and conscious of the dangers the decals indicate on the

machine, you are operating, presents to you and others.

The decals must be maintained in good condition, they are important safety

devices

The following decals are present on this machine:

3 Basic Rules

●Always use the machine across the slope in preference to going up and

down

Use extreme caution when changing direction on a slope

●Do not operate this machine on slopes of more than 20 degrees

Read the safety manual carefully before start up.

Before repair, maintenance and cleaning

Turn off engine and pull out keys

Consider references in the technical manual.

Lubrication fitting

The risk by away-hurling parts with

running engine.

Respect a safety margin from the

m

ac

hin

e

8

Humidity and rain increases the danger of slippage. Certain conditions

may not permit safe handling of the machine

●Wear firm footwear with sufficient profile.

Operate only in conditions where sufficient lighting exists

Check terrain for hidden hazards prior to commencement of operation

In the event of accidental impact with a foreign object, immediately stop

the machine, including engine, and inspect for damage before continuing

Never run whilst operating the machine

Disengage drive to the attachment when transporting machine to and

from area to be worked

Never put hands or feet near or under rotating parts

Prior to any maintenance or repair work ensure that all drives are in the

neutral position, all switches are in the off position and for extra safety

the spark plug lead should be removed

3.1 Before starting

●When starting the engine all drives must be disengaged – i.e. all drive

leavers should be in the neutral rest position

●Never leave the operating position whilst machine is running

●Do not adjust handle bars when operating

Do not operate the machine without all guards and safety devices being

intact

Keep hands and feet always from all rotating parts

●In the event of malfunction stop immediately

3.2 Repair work

●Repair work such as a welding, cutting or drilling must not be carried out

on any safety relevant parts

Damaged parts should be replaced with new before further use of the

machine

3.3 Maintenance

●Examine the machine before start-up to ensure it is in a safe operating

condition, paying particular notice to the security of all screw fittings

Worn/damaged parts should be replaced as a safety precaution

●Cleaning should be carried out regularly to aid visual inspection of all

working parts on the machine, including all safety devices, and to

prevent fire hazards

Cleaning, e.g. with a high pressure cleaner, should be accomplished in

such a way that the water jet is not focused directly on rotating parts,

lubrication points and electrical fittings.

The machine should be maintained according to the instructions

contained within the manual.

●Failure to comply with maintenance and operating instructions will cause

the guarantee to be considered null and void

9

4 Disposal

This device must be disposed of according to the regulation of the municipality

or the country. All possible parts should be recycled and the remainder

disposed of in a satisfactory manner.

The company Kersten Maschinenvertriebs GmbH or Kersten (UK) Ltd does not

take responsibility of disposal.

5 Warranty

Details of Warranty are included on the warranty registration form.

All conditions must be satisfied.

IMPORTANT! Please complete the warranty registration form enclosed and

send it to:

Kersten (UK) Ltd

Progress House, 39 Boulton Road

Reading, Berkshire RG2 0NH

Phone: 0118 986 9253

10

6 Specification

Type K-LINE 820 SWEEPER

Engine Honda 5.5 hp

Fuel Tank .91 litres

Electrical Start n/a

Forward Driving Speed 3km/h

Backwards Driving

Speed

n/a

Hydraulic Oil Tank 7 litres

Hydraulic Oil Avia syntofluid N68 (68 grade biodegradable oil)

Tyre 4.00 x 8

Tyre Pressure Normal running pressure 15psi + or - 2

Parking Brake n/a

Wheel Weights optional

Weights

Dimensions Length

Noise Level Less than 84 db at operators ear

Vibration

additional equipment Wheel weights

Attachments available Front Brush Guard, Collector Box, Sifting Collector, Gulley

Brush, Snow Plough

11

7. Assembly

7.1 Assembly Dirt collector

Attach left and right hand collector height adjustment brackets to the

front of the sweeper housing using counter sunk screws and lock nuts.

Attach the collector to the sweeper by folding the catch lever up. Slide

the container down on to the two adjustable hooks and fold the catch

lever down to lock in to place. (see diagram 1)

7.2 Container - Adjustment:

The height of the container may be altered by means of the black

handles on the height adjustment brackets. There is a graduated

indicative scale. The collector should be set evenly and level with the

front edge 4cm from the surface. The adjustment is affected by the

sweeping brush height and so should be monitored.

As the brush wears adjustments will need to be made.

Attention : Never allow the collector to rub the ground!!!

12

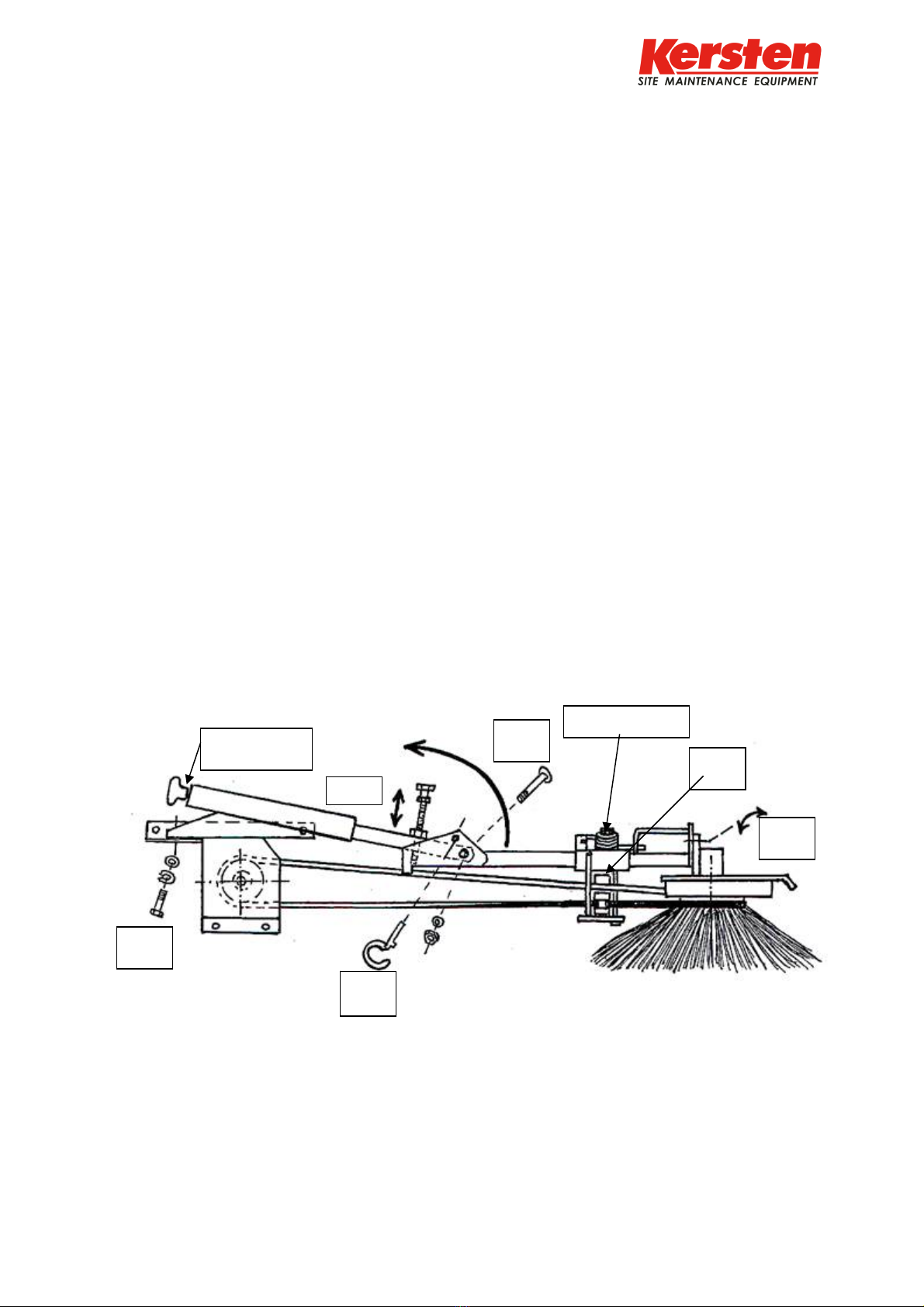

7.3 Assembly - side broom

When attaching the side brush to the sweeper housing for the first time

the drive pulley and support casing needs to be fitted to the right hand

of the sweeper housing as viewed from the operating position. Remove

the 17mm clamping bolt, discard the flat washer. Refit the clamping bolt

including the spring washer and drive pulley. Now mount the support

casing using four screws, lock washers and nuts. The screws should be

outside and the nuts inside. The side brush may now be slid on to the

support casing and secured with the M8 screw and spring washer. “A”.

Insert coach bolt “B” and assemble sweeper head assy. Using 17mm lock

nut and flat washer. Do not over tighten to allow free movement of

sweeper arm. Secure sweeper arm in the upright position with spring clip

“C”

Position the drive belt around the drive pulley within the mounting plate.

The top belt should lay with its back against the white roller at point “X”

and be at the top of the drive pulley.

The belt is tensioned in to the work position by removing spring clip “C”

and folding side brush arm down. Replace spring clip for safe storage.

Correct tension is achieved when a distance of 5mm is measured

between the tension grasp and tube (Point “Z”).

The spring pivot of the gulley brush arm assembly allows lateral

movement in case of obstacles.

“A”

“B”

“X”

Point “Z”

Spring pivot

“H”

“N”

“C”

13

7.4 Adjustment possibilities with the side broom

"H" = height adjustment of the side broom is made by turning grasp “H”.

Anti-clockwise lowers the brush for more contact with the ground.

Clockwise raises the brush for less contact with the ground.

Please note that adjusting the height of the main brush will

affect the height setting of the gulley brush!!

“N” = Angle adjustment for gulley brush head. This may be set by

loosening 13mm screw, adjusting and retightening.

"C" = Allows the brush to become inoperative by folding it out of use.

Lock it in the up position using spring clip to secure it.

Easy removal of the side broom

To dismantle the assembly remove screw “A”, slide assembly forwards

and remove the belt laterally from the drive pulley.

Easy side broom attachment

Fit the drive belt by sliding it over the pulley. Locate the brush assembly

on the mounting plate replace screw “A”.

“A”

“B”

“X”

Point “Z”

Spring pivot

“H”

“N”

“C”

14

8 Operation

Operating instructions - power unit

Handlebar adjustment :

Equally loosen both wing nuts (position1 + pos.2) and

pull the handlebar in for the operator desired height,

now retighten the two wing nuts again.

To fold the handlebar down, release hand wheel (position3) and unhook threaded rod..

Engine start:

Set throttle lever (6) to the start position, (symbol "hare") and pull the starter. After

starting, position the lever to the required position for normal operation between "MAX"

or "MIN" position.

Drives:

Depressing the left lever (position 4) drives the machine forward.

Broom drive :

Depressing the right hand lever (position 5) engages the sweeping brush

Pos. 2Pos. 1

Pos. 4 Pos. 5

Foldin

g

handlebar wheel Pos. 3

Handleba

r

Throttlel Pos. 6

15

9 Operating instructions - sweeping machine:

Height adjusters “A” control the brush depth settings . Twisting them

clockwise will lower the brush – anticlockwise will raise the brush. The

base setting from which to work is when 40mm of the brush is in contact

with the surface to be swept. Always adjust the brush evenly to achieve

even wear.

The graduation scale on the side of the adjusters provides an indication of

setting.

(see sketch 1)

Sketch 1

10 Collector - adjustment: (see sketch 1)

Height adjusters “B” control the box level settings. Twisting them

clockwise will raise the box – anticlockwise will lower the box. The base

setting from which to work is when box is level to the ground ie there is

a parallel gap of 40mm between the surface to be swept and the bottom

of the box.

The graduation scale on the side of the adjusters provides an indication

of setting.

Note: Sweeping machine collector must never rub the

ground!!!

10.1 Side broom - adjustment:

See assembly – Side broom 3.3

Height adjusters “A”

Height adjusters “B”

16

11 Maintenance

11.1 General information

Note!

Injuries to people or Damages to the machine can occur.

You should check before each use that the machine is safe and

the relevant parts and hydraulic connections are properly

connected.

11.2 Maintenance

●The sweeping machine must be submitted to regular maintenance.

●After use you must dismantle all the safety devices for reattachment

when the machine is used again.

●check all fixings and pin connections after the first 5 hours of use

and lubricate all mobile parts

●check the tightness of the hydraulic fittings before every use.

●check hydraulic fittings after 5 hours use for the first time, and tighten

if necessary

(Important note: Only tighten joint if it is leaking. Procedure:

Loosen the screw connection then move hose left and right. Now

the screw connection can be tightened again.

11.3 Daily maintenance

●check the safety and control parts for wear before every use.

●check the oil level and Air filter.

●check the Hydraulic fittings and linings

●check the air pressure in the wheels.

●do a test run before every use.

●clean the equipment after every use.

●regularly lubricate all adjustable and moving parts on the power unit and

any attachments.

Storage settings

Sweeping brush:adjust wheels so that the brush is off the floor making

sure the sweeping brush is evenly relieved

●Side brush: only store off the ground.

11.4 Maintenance after 20 and 100 hours use or longer

All mobile parts must be greased and oiled regularly including at the

beginning and the end of each season.

Oil change Honda motor:

Change For the first time after 20 hours use, then every 100 hours use

after that for further information, see engine manual.

Hydraulic oil change:

The hydraulic oil and oil filter should be changed after the first 20 hours

and then after every 100 hours

Type of oil used: BP Biohyd SE-S46 (biologically degradable Ester based)

or similar.

Check chain tension between hydraulic motor and differential.

17

11.5 Installing a replacement sweeping brush

Remove the 17mm long clamping bolt from the sweeping machine

housing Loosen the three screws on the bearing housing and remove

clamp and bearing assembly. Take the square drive tube out of the two

sectioned sweeping brush and remove brushes.

Install new brush - so that the round 145mm recess is on the right as

shown and fits over the hydraulic motor - see sketch. Then reinstall the

drive tube in reverse with the clamp and the square bar, and install the

left hand bearing and clamp.

Hydraulic

Motor this

end

17 mm screw from

this end

18

12 Disposal

These devices must be disposed of according to the regulations of the

municipality or the country. All possible parts should be recycled and the

remainder disposed of in a satisfactory manner.

The compnay Kersten does ot take responsibility of disposal.

13 Warranty

Details of Warranty are included on the warranty registration form. All

conditions must be satisfied. Please complete the warranty registration

and send it to:

Kersten (UK) Ltd

Progress House, 39 Boulton Road

Reading, Berkshire RG2 0NH

Phone: 0118 986 9253

19

14 Certificate of conformity

Certificate of Conformity by the manufacturer (article 8 of the guideline 98/37/EG)

We,

Kersten Maschinenvertriebs GmbH

Empeler Straße 93-95

D - 46459 R e e s

explain that the machine:

Hand-guided front sweeping machine with combustion engine

Trade mark: Kersten

Type: K 820

with the following EEC guidelines agrees: 98/37/EG

Machine type: ______________________

Machine Number: ________________

_____________________

Rees, den 26.04.04 Dipl.-Ing. Georg Kersten

-Geschäftsführe

20

PARTS

1. Drives

Table of contents

Other Kersten Blower manuals