INSTALLATION

Specifictions

Optical Performance

Delivered Lumen Output

Beam Angle

(1 in/ 25.4 mm recess)

9W 13W 18W

15° beam low glare 650 lm 882 lm 1092 lm

25° beam, low glare 623 lm 845 lm 1046 lm

40° beam, low glare 569 lm 772 lm 955 lm

60° beam, low glare 561 lm 760 lm 941 lm

15° beam high output 682 lm 928lm 1148 lm

25° beam, high output 678 lm 923 lm 1142 lm

40° beam, high output 646 lm 878 lm 1087 lm

60° beam, high output 630 lm 857 lm 1061 lm

CRI (Ra)3 >90 (R9>90) 2400K5000K TYP

Lumen Maintenance 50,000 hours to L70 @ 25 ˚C TA

Color Spatial Uniformity <2 MacAdam ellipses across

field angle

Color Point Range 1400 ˚K10,000 ˚K, Fully

Saturated, Pastel

Equivalent Traditional Lamp 75 W halogen

Dimming Range 0.1100% lm

Power Consumption D3.13 13 W

D3.18 18 W

Voltage* 120 V 60 Hz

220277 V 60 Hz

220277 V 50 Hz

Power Factor >0.9

Current 150 mA Max

Delivered Ecacy

Beam Angle

(1 in/ 25.4 mm recess)

9W 13W 18W

15° beam low glare 72 lm/W 68 lm/W 61 lm/W

25° beam, low glare 69 lm/W 65 lm/W 58 lm/W

40° beam, low glare 63 lm/W 59 lm/W 53 lm/W

60° beam, low glare 62 lm/W 58 lm/W 52 lm/W

15° beam high output 76 lm/W 71 lm/W 63 lm/W

25° beam, high output 75 lm/W 71 lm/W 62 lm/W

40° beam, high output 72 lm/W 68 lm/W 59 lm/W

60° beam, high output 70 lm/W 66 lm/W 58 lm/W

Surge Protection 2.5 KV

Control Protocol KetraNet Mesh

Environmental

Operating Temperature 040 °C

Storage Temperature -2080 °C

Humidity 095%, Non-condensing

Certification UL, cUL, RoHS, FCC Class B

Location UL Damp Location, UL Wet

Location Available with Lens Trim

Electrical

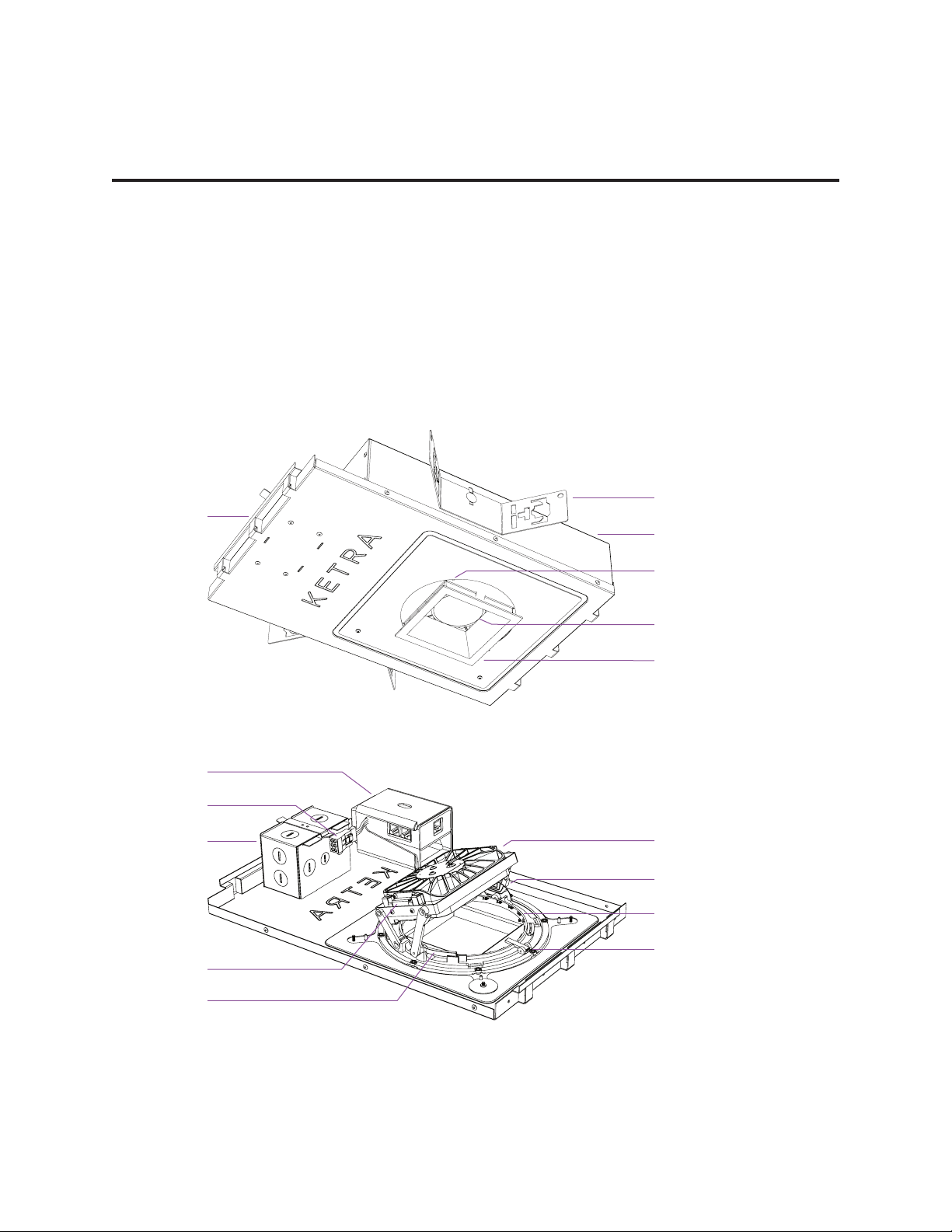

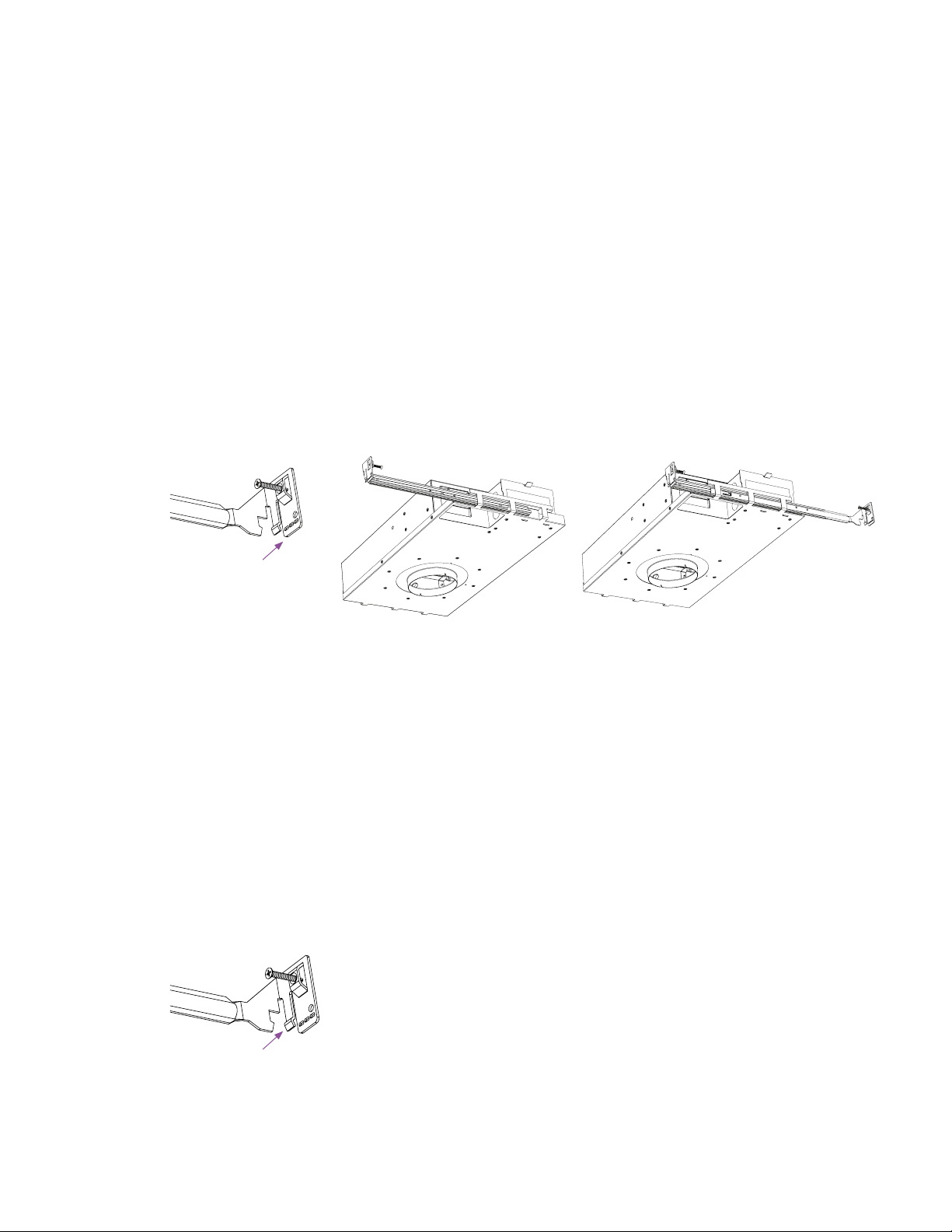

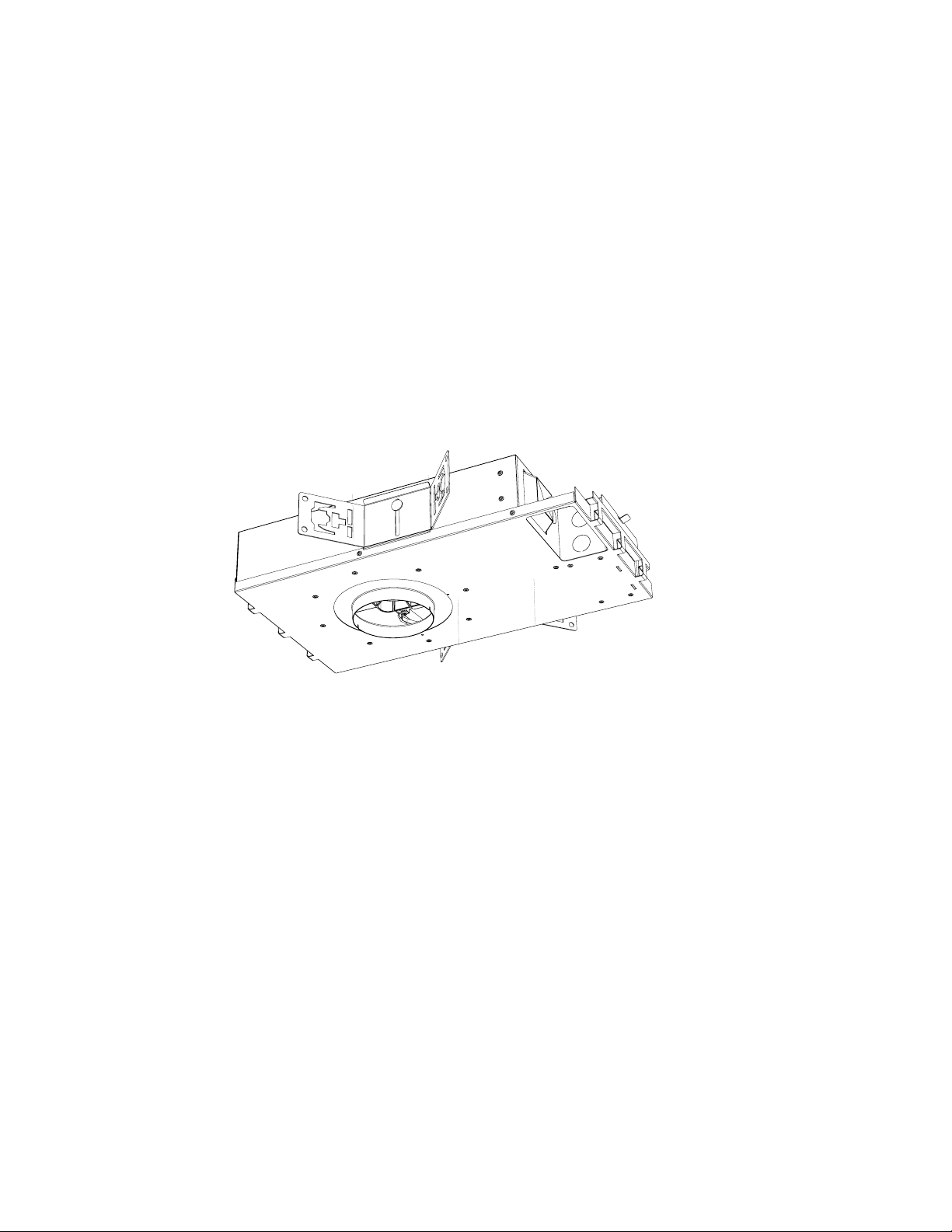

Mounting Options Hanger Bars / Butterfly Brackets

Field Replaceable Optics Yes

Field Replaceable

Light Engine

Yes

Field Replaceable

Power Supply

Yes

Additional Optic Lens Holder 2.5 in/63.5 mm Lens, ⁄ in/3.175 mm Thick

Additional Trim Lens Holder 2.75 in/69.85 mm Lens, ⁄ in/3.175 mm Thick

Housing Material Powder Coated Steel, Polymer

Lens Material Glass

Dimensions

Ceiling Hole Diameter 4 in/ 101.6 mm Flanged,

5.5 in/ 139.7 mm Mud-in

Trim Outside Diameter 4.62 in/ 117.348 mm

Trim Inside Diameter 3.75 in/ 95.25 mm

Trim Thickness ⁄ in/ 1.5875 mm

Optics Outside Diameter 2.5 in/ 63.5 mm

Trim Depth 1 in/ 25.4 mm

Ceiling Thickness 0.625 in–1.5 in/ 15.87538.1 mm

Emitter Vertical Adjustment

(tool-free)

0.75 in/ 19.05 mm

Housing Vertical Adjustment

via Butterfly Bracket

1.75 in/ 44.45mm

Housing Height 3.50 in/ 88.9 mm

Housing Length 18.38 in/ 466.852 mm

Housing Width 10.07 in/ 255.778 mm

* Ketra lighting products should not be connected to, or directly controlled by, AC mains line voltage dimmers. These types of dimmers may

also be referred to as phase cut, triac, forward-phase, reverse-phase, ELV, or MLV dimmers. Ketra's lighting products should only be controlled

via our digital control architecture. Ketra does not recommend switching power on/o to Ketra lighting products via relays, contactors, or

manual toggle switches. When the lighting products are disconnected from power they cannot respond to digital commands from control

devices. This could confuse end users as the lighting may be in a state that is inconsistent with the control devices. Please refer to our controls

products installation guides for more information.

6|D3 INSTALLATION GUIDE

P/N 040444 Rev E

© 2019 Ketra, Inc. All rights reserved