Speed Controller Installation & Operation

Refer to Factory Label to determine which speed controller is on the unit and use the following tableto nd the appropriate

installation instructions.

Sample line string: Krown-X-X//I/SUPPLY/24/48//RSR/HEPA/FC/ECM/115/CF/R+TMB/FL+ML+BACnet/BFC/TC/DSW-

115//ASSP///WPF/PL-AL/F-AL/PL-B12/F-B12

Speed Controller Page Reference

PSCSC/WK 4

ECMSC 5

BFC 8

PSCSC/WK

Sample line string: Krown-X-X//I/SUPPLY/24/48//RSR/HEPA/FC/PSC/115//R+TMB/FL+ML/PSC-WK/TC/DSW-115//

ASSP///WPF/PL-AL/F-AL/PL-B12/F-B12

If unit does not have the wall kit (WK) option, proceed to step 4.

Sample line string: Krown-X-X//I/SUPPLY/24/48//RSR/HEPA/FC/PSC/115//R+TMB/FL+ML/PSCSC/TC/DSW-115/PC-115/

ASSP///WPF/PL-AL/F-AL/PL-B12/F-B12

PSC Speed Controller with Wall Kit Option

Step 1: Locate pre-installed electric

box for wall-mounted speed

controller.

Step 2: Wire speed controller

according to wiring diagram. Wall-

mounted speed controller will be

wired in series with the motor.

Step 3: Attach the wall-mounted

controls faceplate to the electrical

box using the screws provided.

Step 4: Wire the unit according

to appropriate wiring diagram. If

Power Cord (PC) option is selected,

simply insert plug end into

electrical socket.

Sample line string: Krown-X-X//I/

SUPPLY/24/48//RSR/HEPA/FC/

PSC/115//R+TMB/FL+ML/PSCSC/

TC/DSW-115/PC-115/ASSP///

WPF/PL-AL/F-AL/PL-B12/F-B12

Step 5: If the unit has an RSR lter

install the lter now, refer to the

lter installation section of this

manual for instructions.

Step 6: Ensure proper voltage is

hooked up to the unit.

Step 7: Proceed to the balancing

section of this manual.

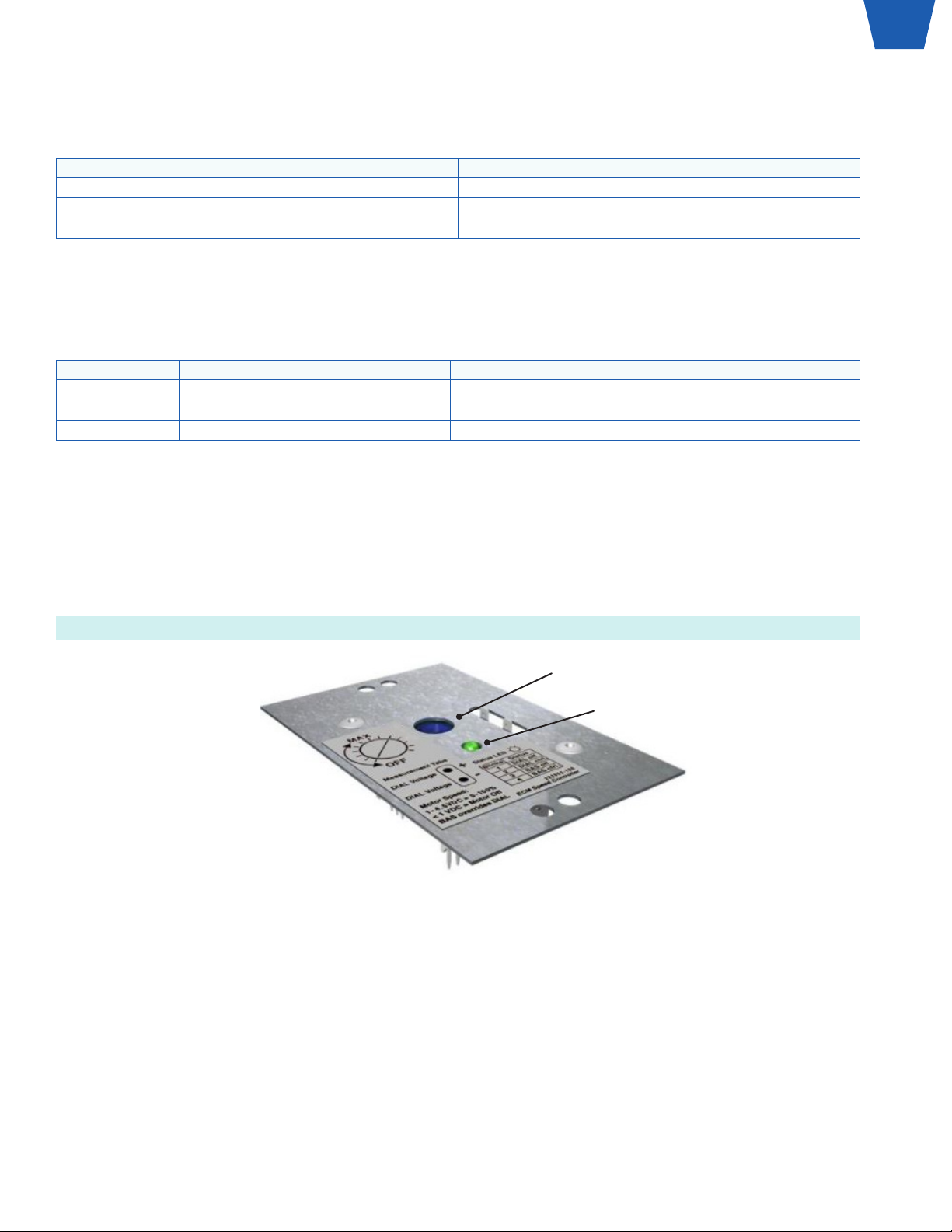

NOTE: Clockwise rotation will

increase airflow, counter-clockwise

rotation will decrease airflow.

NOTE: If unit is ducted, refer to

Technical Note: Balancing Ducted

Units.

For more information visit KeystoneCleanAir.com v001

6

Krown Fan Filter Units | Installation Instructions