Kieback&Peter GmbH & Co. KG

Tempelhofer Weg 50, 12347 Berlin/Germany

Telefon: +49 30 60095-0, Telefax: +49 30 60095-164

www.kieback-peter.de, info@kieback-peter.com

Datasheet 2.50-40.051-71-EN

SBM51/06

Issue 2013-06-20

A

Änderungen vorbehalten - Contents subject to change - Sous réserve de modifications - Reservado el derecho a modificación - Wijzigingen

voorbehouden - Con riserva di modifiche - Innehåll som skall ändras - Změny vyhrazeny - Zmiany zastrzeżone - Возможны изменения -

A változtatások jogát fenntartjuk - 保留未经通知而改动的权力

Product Description

SBM51/06 Gateway Module for Danfoss Frequency

Inverters

Application

The SBM51/06 gateway module can be used to connect up

to eight different types of Danfoss frequency inverter (FI), via

the Danfoss bus, to the DDC3000/DDC4000 automation

system. The connection is made via the RS485 interface of

the SBM51/06. Danfoss FC protocol is used for communi-

cation.

You can use the following Danfoss series:

VLT 2800 series, VLT 5000 series, VLT 6000 series, VLT

HVAC Drive FC 102, VLT AQUA Drive FC 202, VLT Automa-

tionDrive FC 301, VLT AutomationDrive FC 302, VLT Micro

Drive FC 51

Content Page

Important Information Regarding Product Safety ..................................................................................................2

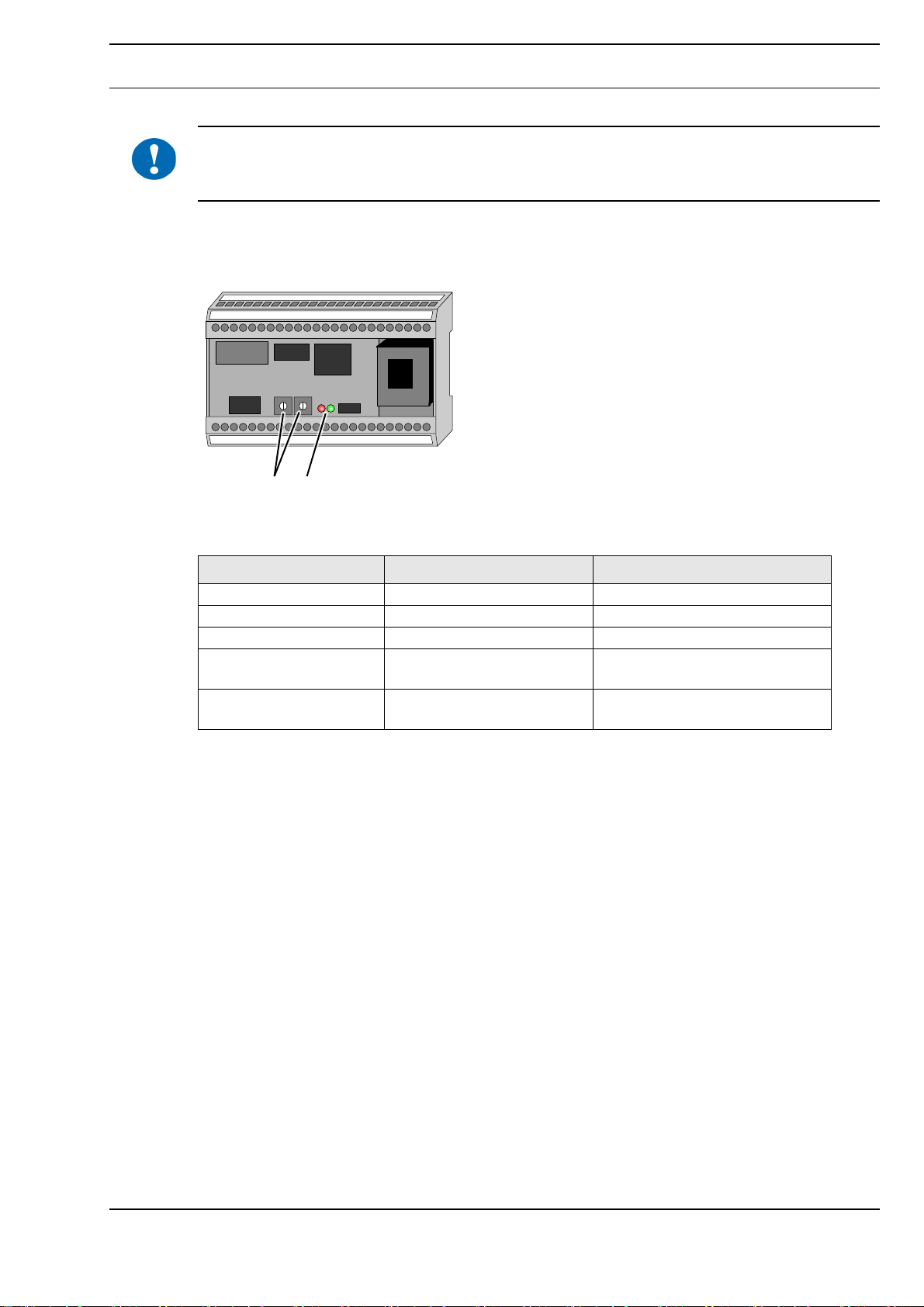

Item........................................................................................................................................................................3

Technical Data.....................................................................................................................................................3

Dimensions..........................................................................................................................................................3

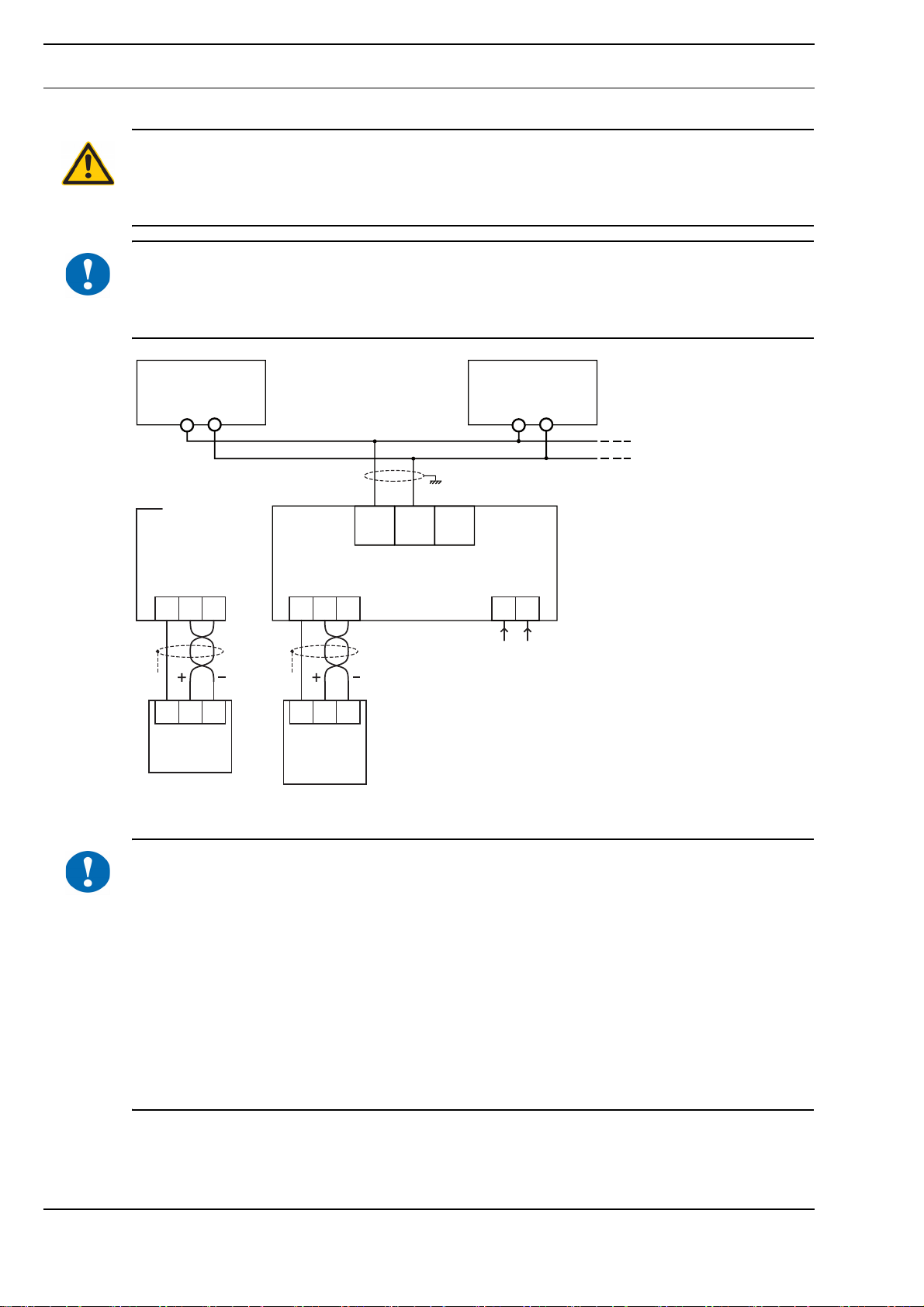

Connection...........................................................................................................................................................4

Installation and Removal .......................................................................................................................................6

Commissioning ......................................................................................................................................................7

Switching on the Power .........................................................................................................................................9

SBM51/06 Parameter Description .......................................................................................................................10

Basic Program ...................................................................................................................................................10

Parameter Lists for the DDC Software Menus M090 and CD_SB51 (SBM51 Gateway) ..................................12

Project Planning: Frequency Inverter - SBM51/06 ..............................................................................................20

Determining Speed (Using the VLT 6000 as an Example) ................................................................................20

Malfunction messages .......................................................................................................................................20

V-Belt Monitoring (Load shedding) ....................................................................................................................20

Comparison Tables for the Software Menu M090 and CD_SB51: Parameter - Data Points...............................22