25.4.12

Operation instructions: Control head 5630xxx010-000

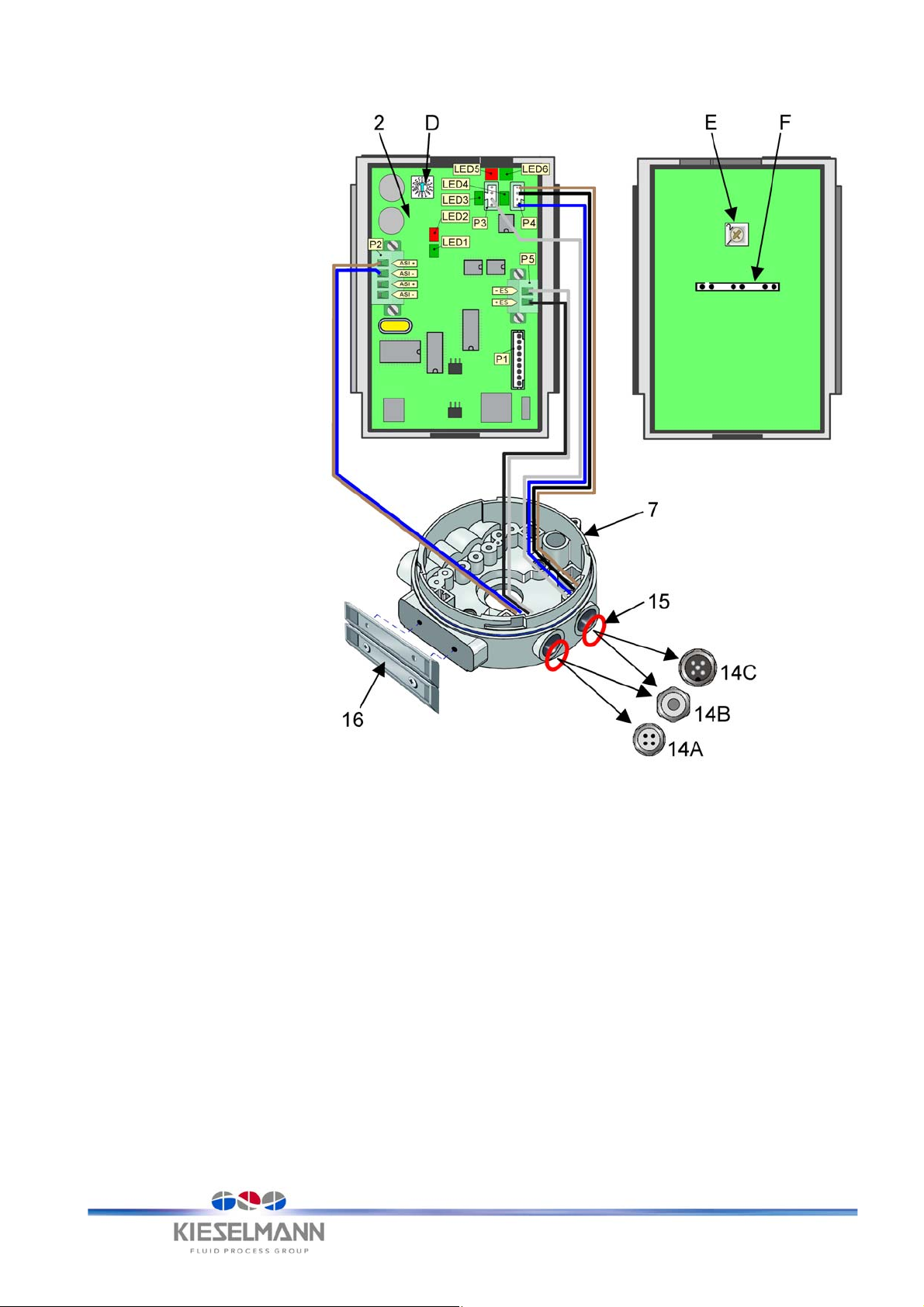

ASi-Bus ES/ABSL

2

1. List of contents ..............................................................................................................2

2. Information for your safety............................................................................................. 3

3. Marking of safety instructions in the operating manual ................................................. 3

4. Variants of control heads ASi-Bus ES/ABSL................................................................. 4

4.1 Double seat valve (pneum. Lifting valve) ............................................................ 4

4.2 Single seat valve (pneum. Lifting valve).............................................................. 4

4.3 Butterfly valve / Ball valve (pneum. Rotary valve).............................................. 4

5. Safety instructions........................................................................................................ 5

5.1 Field of application .............................................................................................. 5

5.2 General safety instructions.................................................................................. 5

5.3 General notes ..................................................................................................... 5

6. Function ........................................................................................................................ 5

6.1 Description of function ........................................................................................ 5

7. Maintenance.................................................................................................................. 5

8. Installation informations................................................................................................. 5

8.1 Installation instructions........................................................................................ 5

9. Initial operation .............................................................................................................. 6

10. Power supply / valve control.......................................................................................... 6

10.1 Standard variant.................................................................................................. 6

10.2 ES variant (plug P5)........................................................................................... 6

10.3 Switch-over Standard / ES (selector switch E).................................................... 6

10.4 JTAG Interface (plug P1) ................................................................................... 6

10.5 External inputs 1 (plug P4) and 2 (plug P3) ........................................................ 6

10.6 Valve interface (plug F)..................................................................................... 6

11. Electrical installation......................................................................................................7

11.1 Electrical connection of the control head ............................................................ 7

11.2 Terminal pin assignment ..................................................................................... 7

11.3 LED Indication of slave status / Selector switch (D)........................................... 7

11.4 Electrical connection design of control head ASi-Bus ES/ABSL......................... 8

12. Position control and position indication ......................................................................... 9

12.1 Lifting valve ......................................................................................................... 9

12.2 Rotary valve ...................................................................................................... 10

13. Electrical and pneumatical piloting ASi-Bus ES/ABSL................................................ 11

13.1 Valve piloting - Double seat valve ..................................................................... 11

13.2 Valve piloting - Lifting valve............................................................................... 12

13.3 Valve piloting - Rotary valve.............................................................................. 13

13.4 Bit-assignment external input............................................................................ 13

14. Demontage und Montage............................................................................................ 14

14.1 Disassembly...................................................................................................... 14

14.2 Assembly .......................................................................................................... 14

15. Spare parts list ............................................................................................................ 15

16. Technical data ............................................................................................................. 16

17. Fault clearance............................................................................................................ 16

1. List of contents