T23_AA_Operator Manual_2014 Revised 08/2014

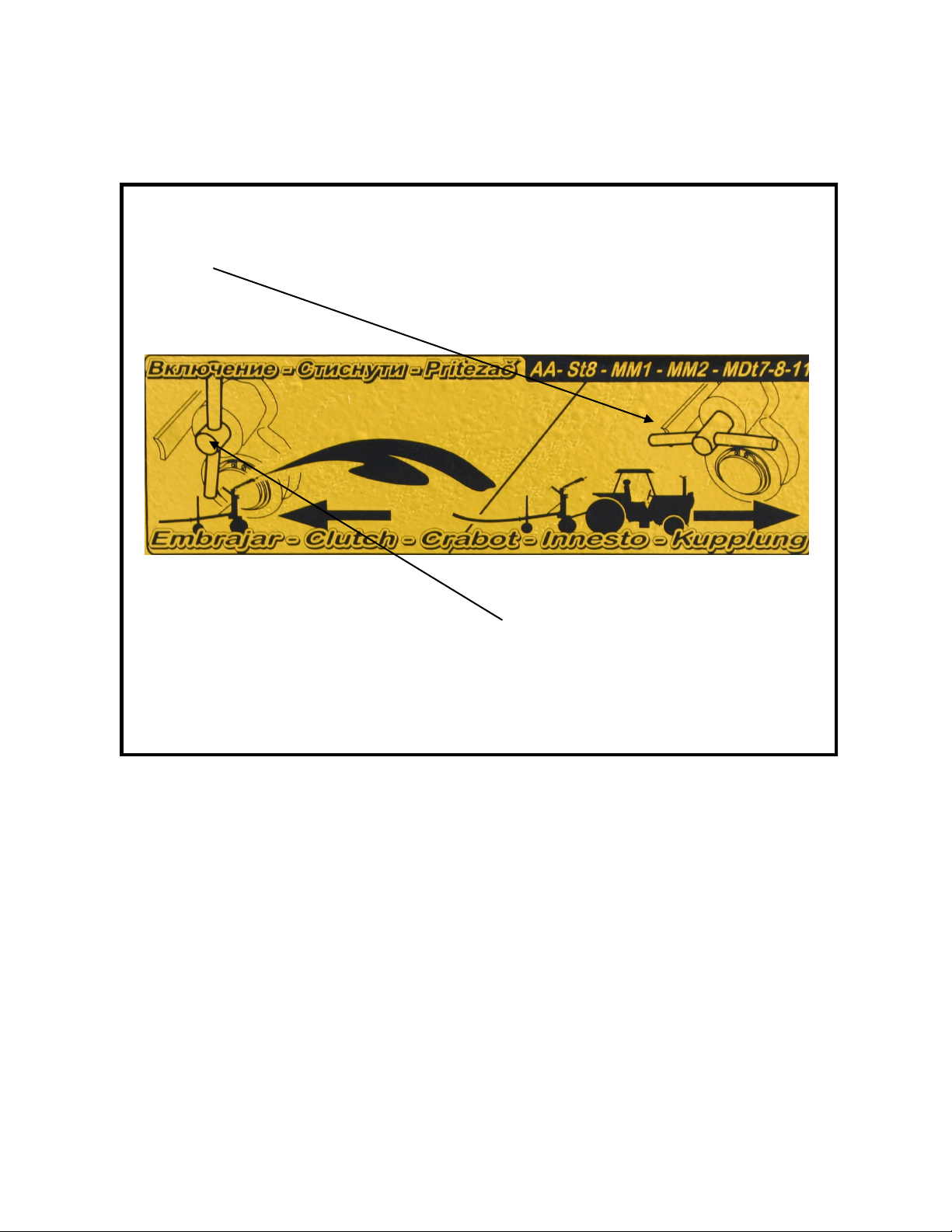

Polyethylene Tube

Precauons for Handling

The polyethylene irrigaon tube is a durable product that will operate reliably for many years if handled

properly and given a reasonable amount of care.

Medium Density Polyethylene is a semi-rigid product that retains its shape when it is not pressurized but can

also be wound on a drum or spool without damage. This characterisc makes it feasible to pump uid through

it while it is rolled up on a reel.

A few simple precauons need to be observed to prevent damaging the tube when operang your Water-Reel.

1. When starng a new Water-Reel for the rst me, you must pull the tube all the way out in order to

correctly ghten the new tube on the spool. It is also important to follow the ming Instrucons on

Page 30 of this manual. The Water-Reel must be med on the rst run.

2. Never transport the Water-Reel with the an-return pawl disengaged! The tubing will become loose and

tangled. Do not aempt to operate your Water-Reel if there are any coils of tube that are loose or mis-

placed. If loose coils of tube are noced aer pulling the tube out, they must be ghtened by rotang the

spool with the hand crank. If this is not possible, pull all of the tube out before aempng to rewind the

tube.

3. Never try to move or relocate the machine if the tube is not fully rewound onto the machine.

4. Never pull the tube o the machine other than by pulling on the sprinkler cart (straight out from the ma-

chine).

5. Never run over the tube with any kind of vehicle and avoid pinching or pulling the tube around objects.

Never bend the tube sharper than 25 mes the inner diameter of the tube.

6. If the tube is frequently pulled out only a poron of its complete length the tube remaining on the drum

will become loose. Occasionally it will be necessary to pull all the tube o the drum to ghten the remain-

ing coils.

7. Be careful when operang other equipment near the tube. Make sure the tube doesn’t get gouged or

punctured.

8. Never leave tube pulled out on ground for more than 12 hours prior to your irrigaon run.

9. Avoid using the PTO or engine drive to rewind the tube when it is not pressurized. When the tube is not

pressurized during rewind the tube will aen and the rewind mechanism cannot funcon properly. Keep

the tube pressurized when rewinding!

10. The Water-Reel’s gearbox is equipped with a brake to prevent coils of tube from becoming loose on the

tube spool due to freewheeling of the drum. Loose coils of tube will make the level-wind mechanism ap-

pear to be out of me. In this case, the level-wind system will be damaged and a mis-wrap will occur.