Wall Mounted Systems

15 Wentworth Place, Banyo Qld 4014

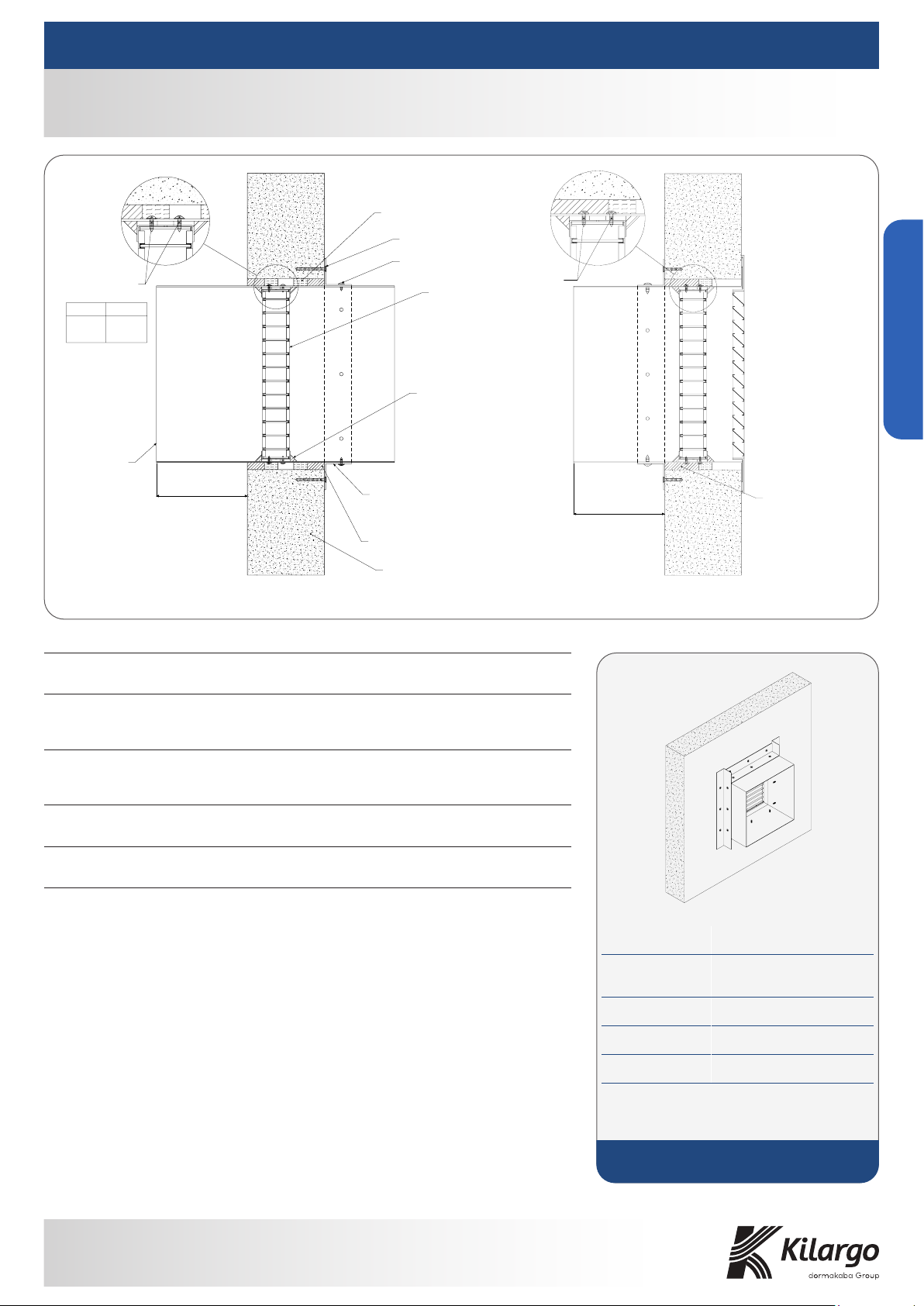

Step 1 Position damper centrally in penetration aperture as per system drawing with

IBS Backing Rod and temporary supports or packers.

Step 2 Apply Kilargo Intumescent Mastic (supplied separately) to the gaps between

the damper & building element. Ensure fill depth corresponds with those

detailed in the system drawing.

Step 3 Fasten mounting angles to damper with steel self-drilling screws or steel pop

rivets and, if detailed, to the building element with appropriate mechanical

fixings as per system drawing.

Step 4 Ensure product and certification labels are in a prominent position for easy

identification during subsequent maintenance inspections.

Step 5 Connect ductwork to the damper casing with AS 1682.2 compliant breaka-

way joint.

IFD44-LL Series: Hebel

Installation Instructions:

Ducted

System Notes

• Grilles, louvres, IBS backing rod & fixings are to be supplied by others.

• Kilargo Intumescent Fire Dampers shall be installed in accordance with this detail,

including the use of Kilargo Intumescent Mastic and in accordance with the

requirements of AS1682.2.

• Ensure convenient access is provided for visual inspection and cleaning as necessary.

• 2mm Minimum gap allowable between damper and aperture. For gaps between

2-5mm, a fillet of Kilargo Intumescent Mastic shall be applied.

FRL -/120/-

System No. WH11 (a)

Building element: Hebel

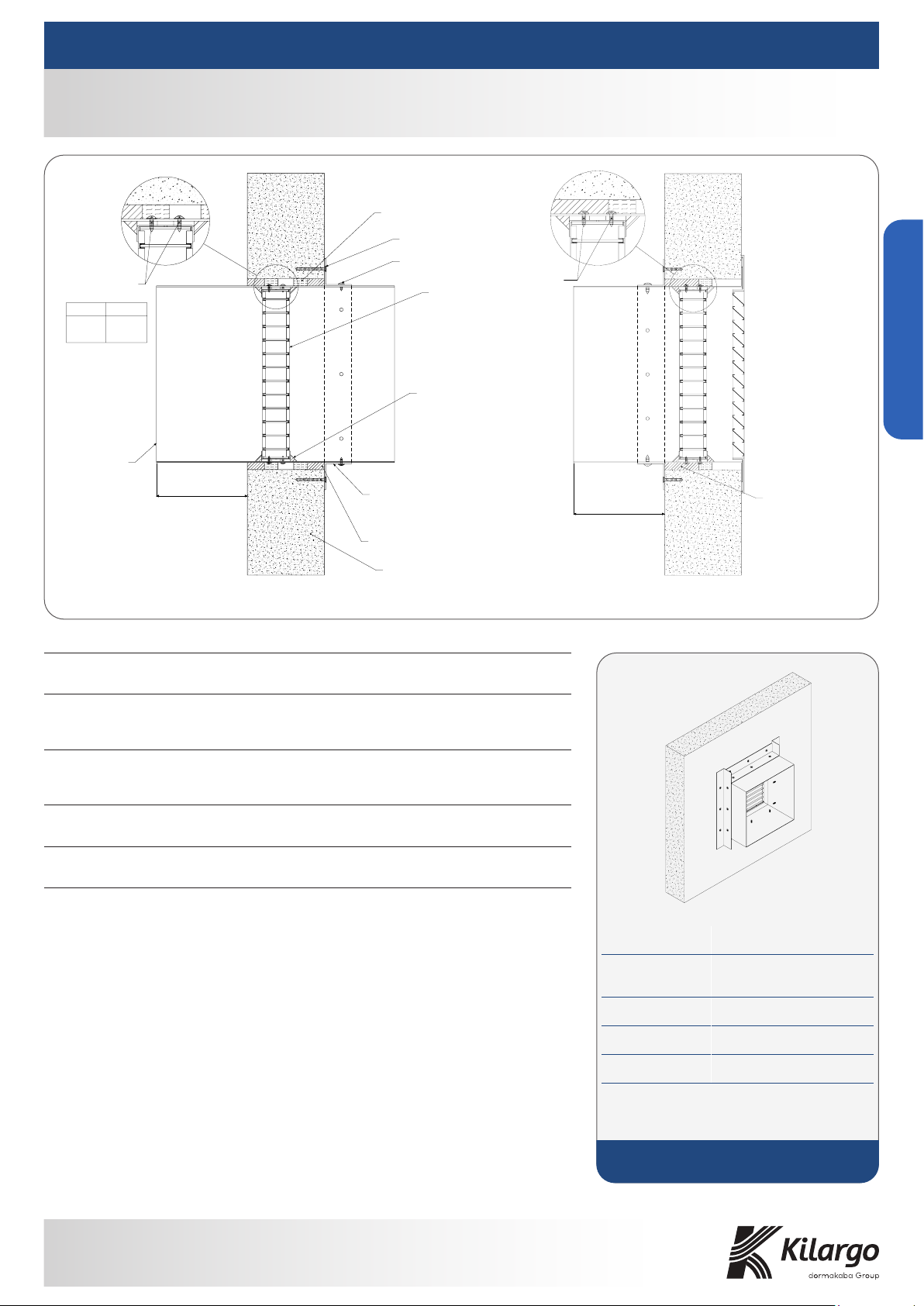

Application: Mounted in casing DD / DG

in 75SW system hebel wall

Maximum size: 300 x 300 *without build up

FRL -/120/-

Test reference No. FAS200229

*Max size 1200 x 1200 if wall thickness is built

up locally with 100mm wide FR plasterboard to

a minimum thickness of 116mm

Duct to Duct Duct to Grille

Casing length 150mm MAX

from face of the wall

Gaps between damper casing and

wall system firestopped with Kilargo

Intumescent Mastic 50mm deep.

Max gap 25mm

Kilargo IFD44-LL fixed

into ductwork with steel

tek-screws or pop rivets

Casing length on either

side of wall 150mm MAX

0.7mm or greater

Z275 gal steel casing

positioned centrally

within aperture

IBS Backing Rod

Kilargo Intumescent

fire damper fixed to

steel casing

Kilargo Intumescent

Mastic applied to entire

perimeter of IFD44-LL

damper (on both sides)

Gaps between casing and

wall system firestopped

with Kilargo Intumescent

Mastic 25mm deep.

Max gap 25mm

Hebel 75SW Wall

Minimum 0.7mm steel angles at least

twice the width of the penetration gap,

fixed to damper casing with steel screws,

bolts or pop rivets and fixed to wall with

steel fixings at maximum 150mm centre

spacing or:

-2 per side for casing lengths up to 250mm

-3 per side for casing lengths 251-400mm

8G x 65mm Coarse Thread Screw

Steel Tek Screw

Kilargo IFD44-LL fixed into

ductwork with steel tek-screws

or pop rivets as follows:

Side Length Qty of Screws

0-100mm

101-250mm

251-400mm

401-600mm

1 set

2 sets

3 sets

4 sets