Issue

G

T.L.

NOV-20 Trading Estate Farnham Surrey England Doc. No. TD 106

Page 6 of 13

AR7187 ISSUE G

Title: Installation & Maintenance – AP Pneumatic Positioner

4.2 Zero and Range Adjustment (refer to Figure 4).

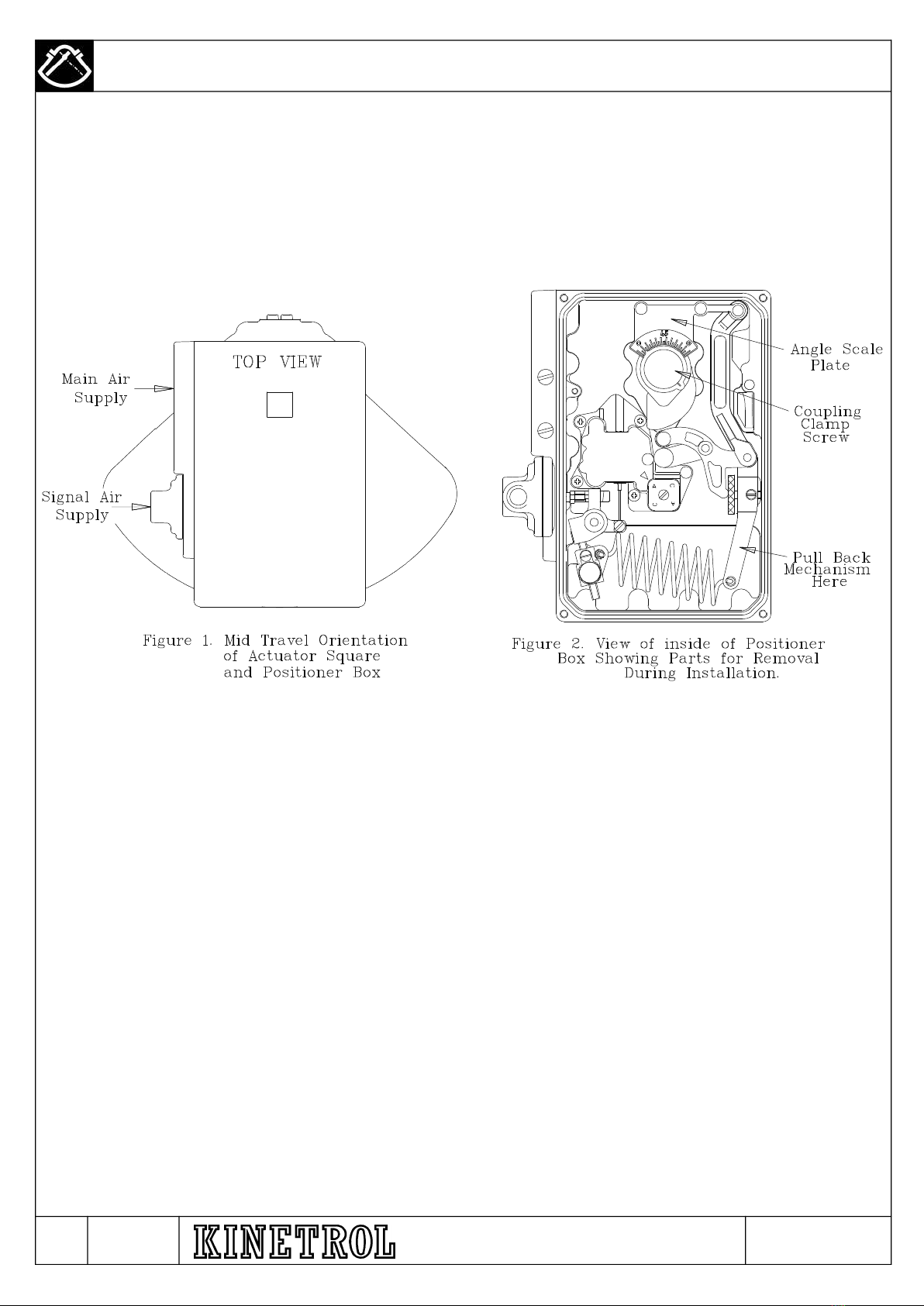

4.2.1 Move the actuator/positioner to the zero end of the stroke (i.e. when the cam follower is at the beginning of its rise).

This can be most easily achieved by pressurising the main air supply without any signal air pressure (spring return models

will already be at this position. Exhaust the supply air and move the internal indicator to indicate just below zero on the

angle scale.

4.2.2 Set the coarse zero by slackening the coupling screw by approximately half of a turn until the top part of the coupling

can be rotated by hand and rotate until the cam follower just starts to rise up the cam profile. Retighten the screw.

4.2.3 Turn on the main air supply and carefully increase the signal supply pressure to 3psi (0.2Bar). Slacken the fine zero

adjustment clamp screw and rotate zero adjuster using thumb pressure so that the actuator moves to indicate zero on the

internal indicator. Tighten clamp screw.

4.2.4 Increase the signal pressure to 15psi (1 Bar). Slacken the range adjuster clamp screw and rotate the adjuster knob

between thumb and forefinger until the actuator moves to the desired end stroke position (normally 90 degrees) as

indicated on the internal indicator. Re-tighten the clamp screw.

4.2.5 Reduce the signal air pressure again to 3 psi and check that the zero position has not changed.

4.3 Speed Control.

Maximum actuator speed can be regulated by the two following methods:

a.) Changing the valve spool/liner size. The valve size is normally specified at the point of ordering by the letters 'AP', 'MP'

or 'HP'. This method, however, not only effects the actuator speed but also effects the 'gain' and therefore control stability

of the unit and care must be taken not to specify a too high flow valve for a given size of actuator. Kinetrol Ltd has

recommendations (shown in the AP literature) for each size of the actuator

or

b.) adjustment of the built in flow restrictors (shown in Figure 4) is achieved using a screwdriver. There are two restrictors,

one for each direction of travel. Clockwise rotation, this will reduce the actuator speed. 'AP' and 'MP' size units with 1/8 or

1/4 ports are controlled in this way but 'HP' size units having 3/8 ports are fitted with external silencer/restrictors which are

adjusted using an allen key fitted down the centre of the adjuster.

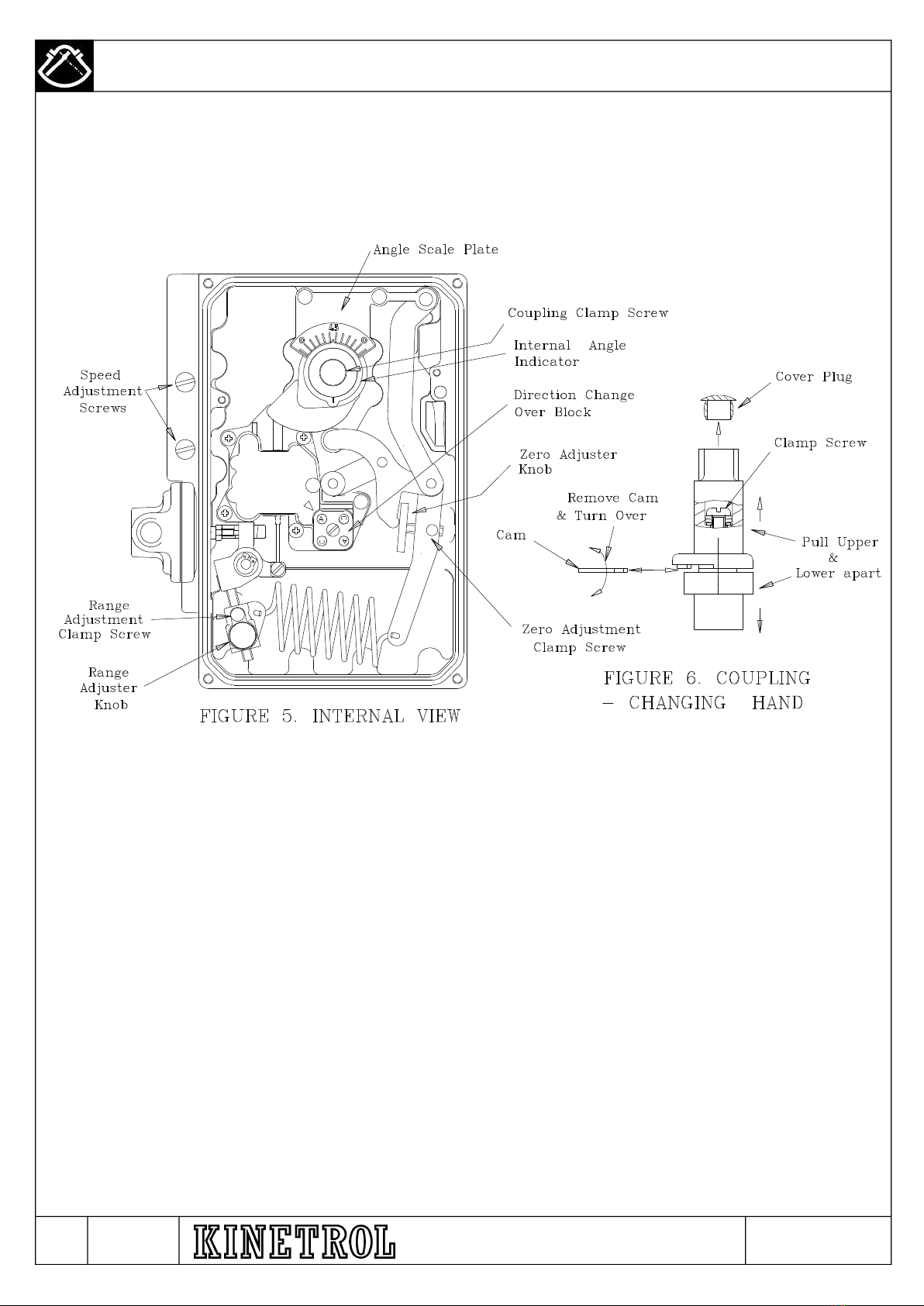

4.4 Change of Direction for Rising Signal (discrete units).

4.4.1 Move actuator as in Section 4.1.1.

4.4.2 Remove positioner cover and undo the three M4 screws retaining the red retransmit plate, as shown in Figure 7.

Loosen the central coupling screw sufficiently to pull the coupling complete with the retransmit assembly off the actuator

connection.

4.4.3 Remove the internal indicator from the coupling and withdraw the coupling from the retransmit plate.

4.4.4 Pull the two halves of the coupling apart sufficiently to allow the cam to be withdrawn from its location peg. Flip the

cam over and push it back into the slot between the two coupling halves and locate it back on the peg.

4.4.5 Refit the coupling to the retransmit plate and slide the internal indicator over the top of the coupling.

4.4.6 If when the coupling was removed, the collet was left behind on the actuator connection, remove the collet from the

connection and push it into the lower half of the coupling ensuring that it locates in the semicircular 'pip' and tighten the

clamping screw by two turns. Place the coupling and retransmit plate back on the actuator connection such that the cam

follower is approximately half way up the rise of the cam and pull back the spring lever with the other hand and tighten the

coupling clamping screw. Re-tighten the retransmit plate retaining screws.

4.4.7 The internal changeover block is not effective with a discrete positioner. The changeover of the airflow path is

achieved by swapping over the external connections. It may also be preferred to turn the positioner through 180 degrees

to simplify the external pipe runs.

4.4.8 The adjustment of zero and range is completed as in section 4.2.