Issue

N

C.S.

04.03.20 Trading Estate Farnham Surrey England Doc. No. TD 120

Page 9 of 25

Title : Installation, Operation & Maintenance Instructions – IS Digital EL Positioner

5.SET UP (Continued)

5.7 Proportional Gain and Damping Settings (for Smoothness and Sensitivity) – continued

The positioner is active while adjusting the PGAIN setting, and continues to follow the input signal. This gives the opportunity to

change the input signal in a manner typical of the application, and to observe qualitatively the response of the positioner, and

how it has been affected by changing the PGAIN setting, so as to optimise the response. Pressing the UP button maximises the

sensitivity and accuracy, at the cost of increased jerkiness of response when the signal is ramped smoothly, and if you go too far

this increases the proportional gain so much that the positioner becomes unstable and hunts around the position set by the

signal. Pressing the DOWN button maximises smoothness during ramping of the signal, at the cost of losing rapidity of response

to small changes in signal. When the right setting has been found, press the SET button again to leave Adjust Mode – the PGAIN

LED will now light continuously.

The DAMP (damping) parameter should be set after the PGAIN has been optimised. In Setup Mode select the DAMP parameter

(second up from PGAIN) by pressing the UP button until the DAMP LED lights continuously. Press the SET button to select

Adjust Mode, and the DAMP LED will blink. Damping can be increased and decreased by pressing the UP or DOWN buttons.

There are twenty nine damping settings which can be selected, the setting altering by a factor of 1.1 each time the UP or DOWN

pushbutton is pressed. The default setting lies in the middle of the range, giving fourteen settings above and fourteen below. Any

button presses beyond the last (fourteenth) setting will have no effect.

Note: As soon as the UP or DOWN button is pressed, the new DAMP value is stored in non-volatile memory, and is retained

even if the positioner is de-energised before leaving Adjust and Setup Modes.

The positioner is active while adjusting the DAMP setting, and continues to follow the input signal. This allows the signal to be

waggled to optimise the response while still adjusting the DAMP setting. Try stepping the signal suddenly so that the positioner

approaches setpoint at full speed having travelled 45 degrees or more, and adjust the DAMP setting to just avoid overshoot here.

Try this travelling up and downscale. When the right setting has been found, press the SET button again to leave Adjust Mode –

the DAMP LED will now light continuously.

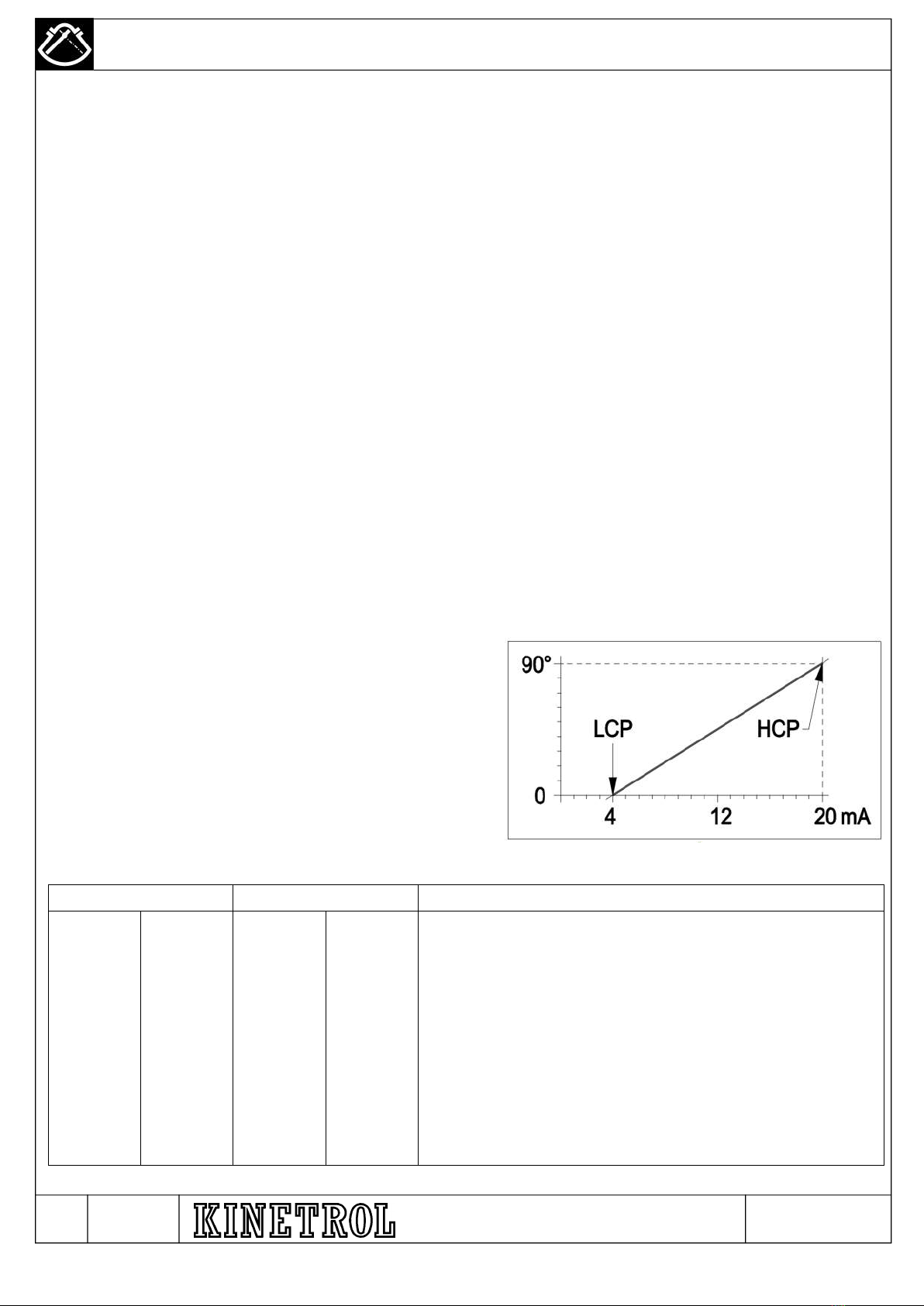

5.8 Low Current Point and High Current Point Settings. (Replaces Zero and Span Adjustment).

The positioner characteristic can be accurately calibrated by setting

two points, the Low Current Point (LCP) and the High Current Point

(HCP). Each point is defined by a position and an input current.

These points can lie anywhere in the range of travel of the actuator,

and in the input signal range of 4 to 20 mA. The only other

restriction is that the input current at the HCP must exceed the input

current at the LCP by at least 5mA. To obtain the best accuracy, it is

necessary to select the two points as far apart as possible. In both

linear and non-linear operation this allows forward acting, reverse

acting, and forward or reverse acting split range characteristics to

be implemented. Table 1 below shows some illustrative examples.

Figure 7. Illustration of LCP and HCP

Low Current Point High Current Point Description

4 0 20 90 Forward Acting, 100% range

4 90 20 0 Reverse Acting, 100% range

4 0 12 90 Split Range Forward Acting, 50% bottom range

4 90 12 0 Split Range Reverse Acting, 50% bottom range

12 0 20 90 Split Range Forward Acting, 50% top range

12 90 20 0 Split Range Reverse Acting, 50% top range

4 0 20 45 Forward Acting, 200% range

4 45 20 0 Reverse Acting, 200% range

Table 1. Various Sets of LCP and HCP Settings

N – AR7059 / M – AR6971 / L - AR6419 / K - AR6347 / J-AR6096 / H – AR 6082 / G – AR 5487 / F – AR 5608 / E - AR 5293