CT9711 / CTD9711 CONTENTS

機型編號說明 Model n

umbering ----------------------------------------------------------------------------------------------------------------------------------

1

1. 規格

Specifications ----------------------------------------------------------------------------------------------------------------------------------

2

2. 搬運

Moving ----------------------------------------------------------------------------------------------------------------------------------

2

3. 安裝說明

Installation ----------------------------------------------------------------------------------------------------------------------------------

3

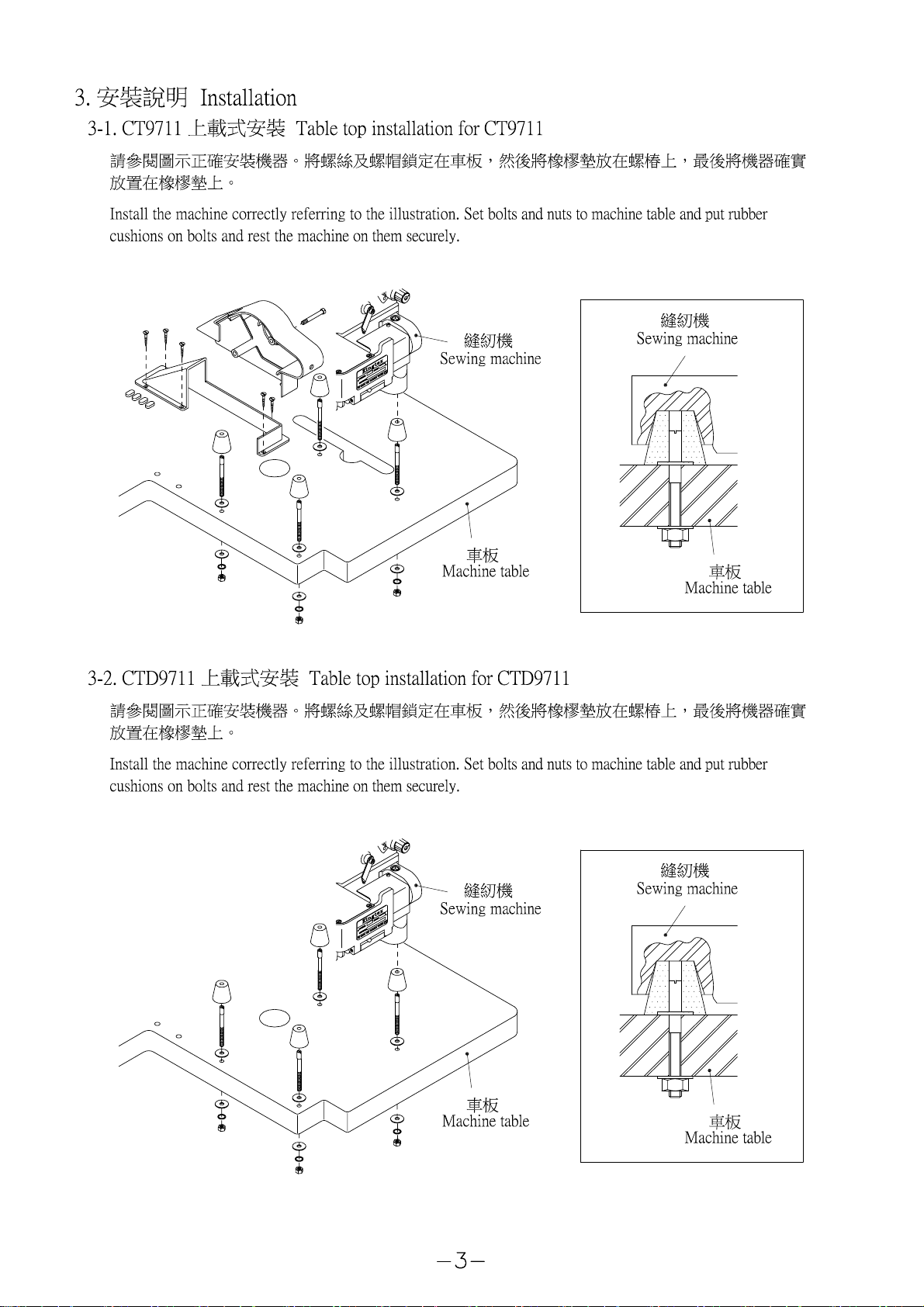

3-1. CT9711 上載式安裝 Table top installation for CT9711

----------------------------------------------------------------------------------------------------------------------------------

3

3-2. CTD9711 上載式安裝 Table top installation for CTD9711

----------------------------------------------------------------------------------------------------------------------------------

3

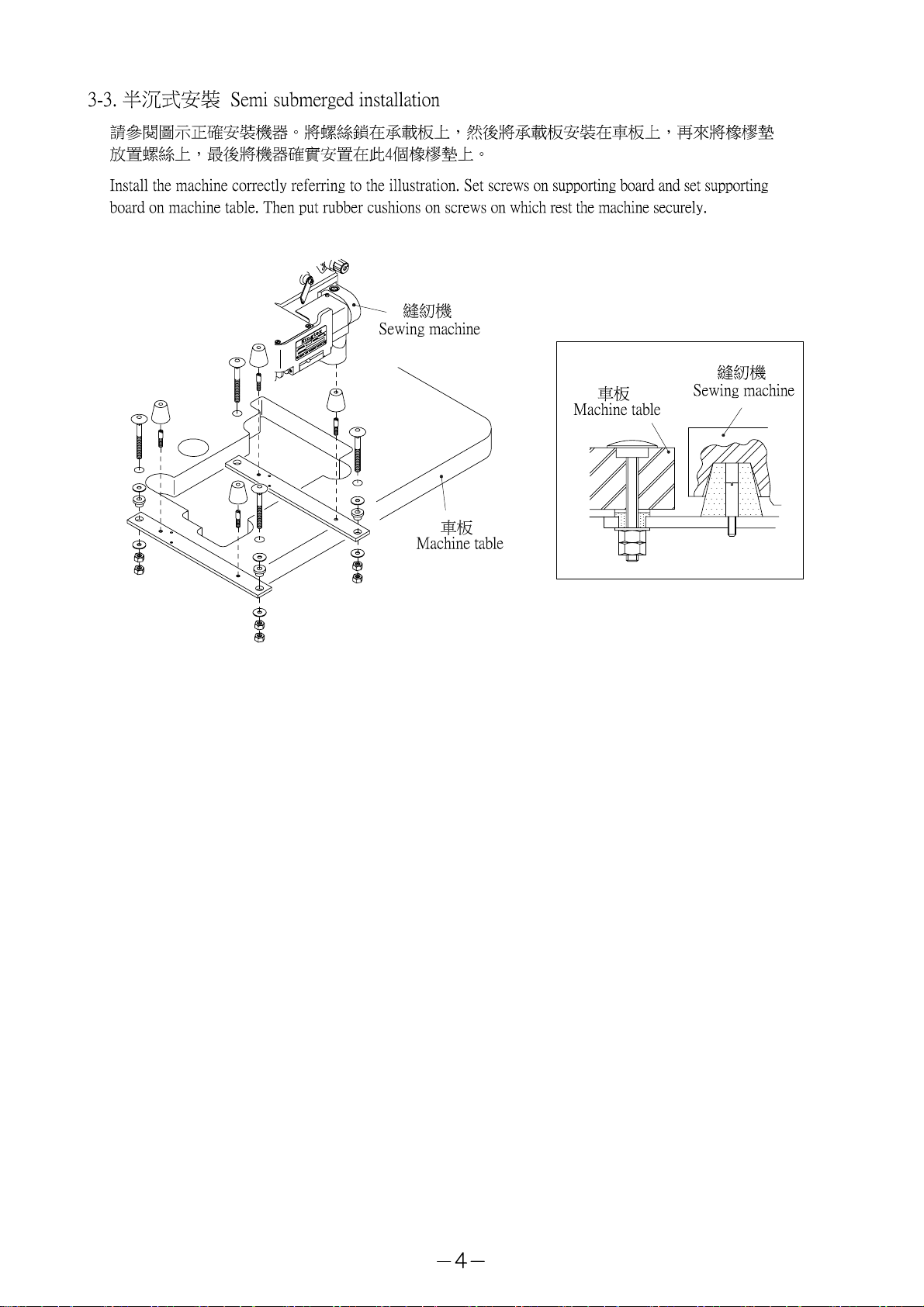

3-3. 半沉式安裝 Semi submerged i

nstallation ----------------------------------------------------------------------------------------------------------------------------------

4

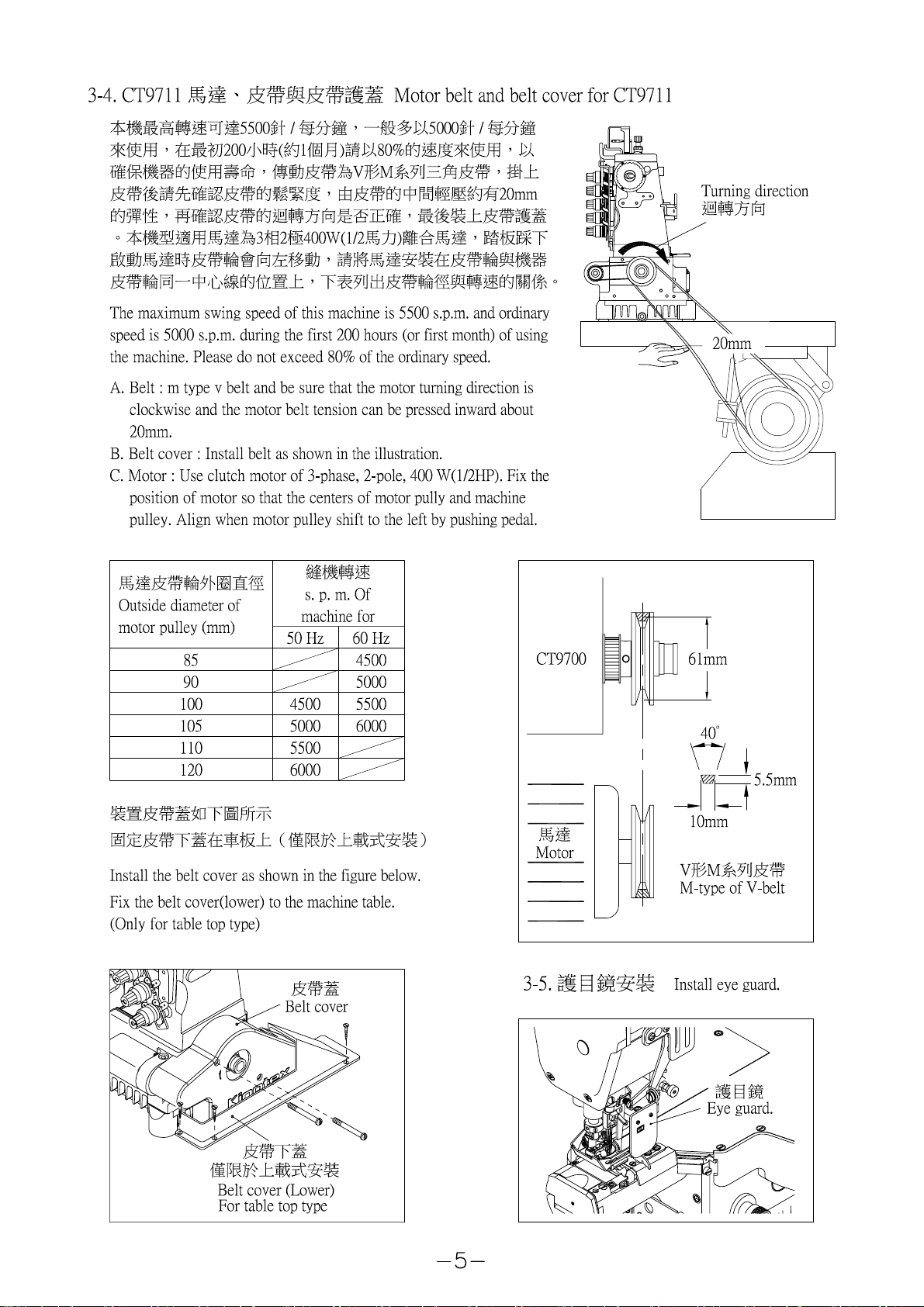

3-4. CT9711 馬達、皮帶與皮帶護蓋 Motor belt and belt cover for CT9711

----------------------------------------------------------------------------------------------------------------------------------

5

3-5. 護目鏡安裝 Install eye guard

----------------------------------------------------------------------------------------------------------------------------------

5

4. 使用前說明 Before o

peration ----------------------------------------------------------------------------------------------------------------------------------

6

5. 潤滑油及冷卻油 Lubrication oil and cooling o

il ----------------------------------------------------------------------------------------------------------------------------------

6

5-1. 選用潤滑油及冷卻油 Lubrication oil and cooling o

il ----------------------------------------------------------------------------------------------------------------------------------

6

5-2. 添加潤滑油 Feeding o

il ----------------------------------------------------------------------------------------------------------------------------------

6

5-3. 換油 Changing o

il ----------------------------------------------------------------------------------------------------------------------------------

6

5-4. 潤滑油過濾器 Oil f

ilter ----------------------------------------------------------------------------------------------------------------------------------

7

5-5. 添加冷卻油 Adding cooling o

il ----------------------------------------------------------------------------------------------------------------------------------

7

6. 針

Needle ----------------------------------------------------------------------------------------------------------------------------------

7

6-1. 針號選擇 Needle s

election ----------------------------------------------------------------------------------------------------------------------------------

7

6-2. 正確的安裝針 How to replace the n

eedles ----------------------------------------------------------------------------------------------------------------------------------

7

6-3. CT9711 穿線 Threading for CT9711

----------------------------------------------------------------------------------------------------------------------------------

8

6-4. CTD9711 穿線 Threading for CTD9711

----------------------------------------------------------------------------------------------------------------------------------

9

7. 與縫製有關的各項調整 Proper operation a

djustment ----------------------------------------------------------------------------------------------------------------------------------

9

7-1. 壓腳壓力 Pressure of presser f

oot ----------------------------------------------------------------------------------------------------------------------------------

10

7-2. 縫線張力 Thread t

ension ----------------------------------------------------------------------------------------------------------------------------------

10

7-3. 進給率調整 Adjusting stitch l

ength ----------------------------------------------------------------------------------------------------------------------------------

10

7-4. 差動比例調整 Adjusting differential feed

----------------------------------------------------------------------------------------------------------------------------------

11

7-5. 針線收放量調整 Adjusting the needle the needle thread t

ake-up ----------------------------------------------------------------------------------------------------------------------------------

12

7-6. 下結線鉤縫線收放量調整 Adjusting the looper thread t

ake-up ----------------------------------------------------------------------------------------------------------------------------------

13

7-7. 上裝飾線收放量調整 Adjusting spreader thread t

ake-up ----------------------------------------------------------------------------------------------------------------------------------

13

8. 與內部機構及時序有關的各項調整 Adjustment of m

achine ----------------------------------------------------------------------------------------------------------------------------------

13

8-1. 更換壓腳及設定提昇高度

Adjusting presser foot and setting the setting the height of presser f

oot ----------------------------------------------------------------------------------------------------------------------------------

14

8-2. 針棒高度及針落點 Adjusting the height of needle bar and needle drop p

oint ----------------------------------------------------------------------------------------------------------------------------------

14

8-3. 安裝下結線鉤 How to install l

ooper ----------------------------------------------------------------------------------------------------------------------------------

15

8-4. 下結線鉤定位 How to set looper p

osition ----------------------------------------------------------------------------------------------------------------------------------

15

8-5. 下結線鉤與針的間隙 The clearance between looper and n

eedle ----------------------------------------------------------------------------------------------------------------------------------

15

8-6. 針與後導針器 Needle and rear needle g

uide ----------------------------------------------------------------------------------------------------------------------------------

16

8-7. 針與前導針器 Needle and front needle g

uide ----------------------------------------------------------------------------------------------------------------------------------

17

8-8. 設定送布齒高度 Setting the height of feed d

ogs ----------------------------------------------------------------------------------------------------------------------------------

17