壓號齔穭貜瑰ㄓO,影響到裁片的進給率正確與否,放鬆固定螺帽旋轉

調整螺樁,向右轉加大壓力,向左轉減小壓力,在不影響縫製效果下,

盡可能減小壓?壓力調整後確實鎖緊固定螺帽

TO INCREASE THE PRESSURE OF PRESSER FOOT,TURN ADJUSTING SCREW (B)

CLOCKWISE AFTER LOOSENING LOCK NUT (A) AND TO DECREASE,TURN IT

COUNTERCLOCKWISE.PRESSURE OF PRESSER FOOT SHOULD BE AS WEAK AS

POSSIBLE SO LONG AS PRESSER FOOT CAN OPERATE PROPERLY.

裁片的厚度,不同質料的縫線,粗細不同的縫線,線跡寬窄的要求,進給率大小的變化都會對縫製的效果

影響,因此必須經過試車調整後,才能找出最佳的縫製效果。

DUE TO THE THICKNESS OF FABRICS, DIFFERENT MATERIALS DIFFERENT KINDS OF THREAD,DIFFERENT

STITCH REQUIREMENTS THE CHANGES OF DIFFERENTIAL RATIO, ALL IS AFFECTING THE SWING

PERFORMANCE.THUS,MUST CONDUCT THE PROPER OPERATION ADJUSTMENT IN ORDER TO GET BEST SEWING

EFFECTS.

7

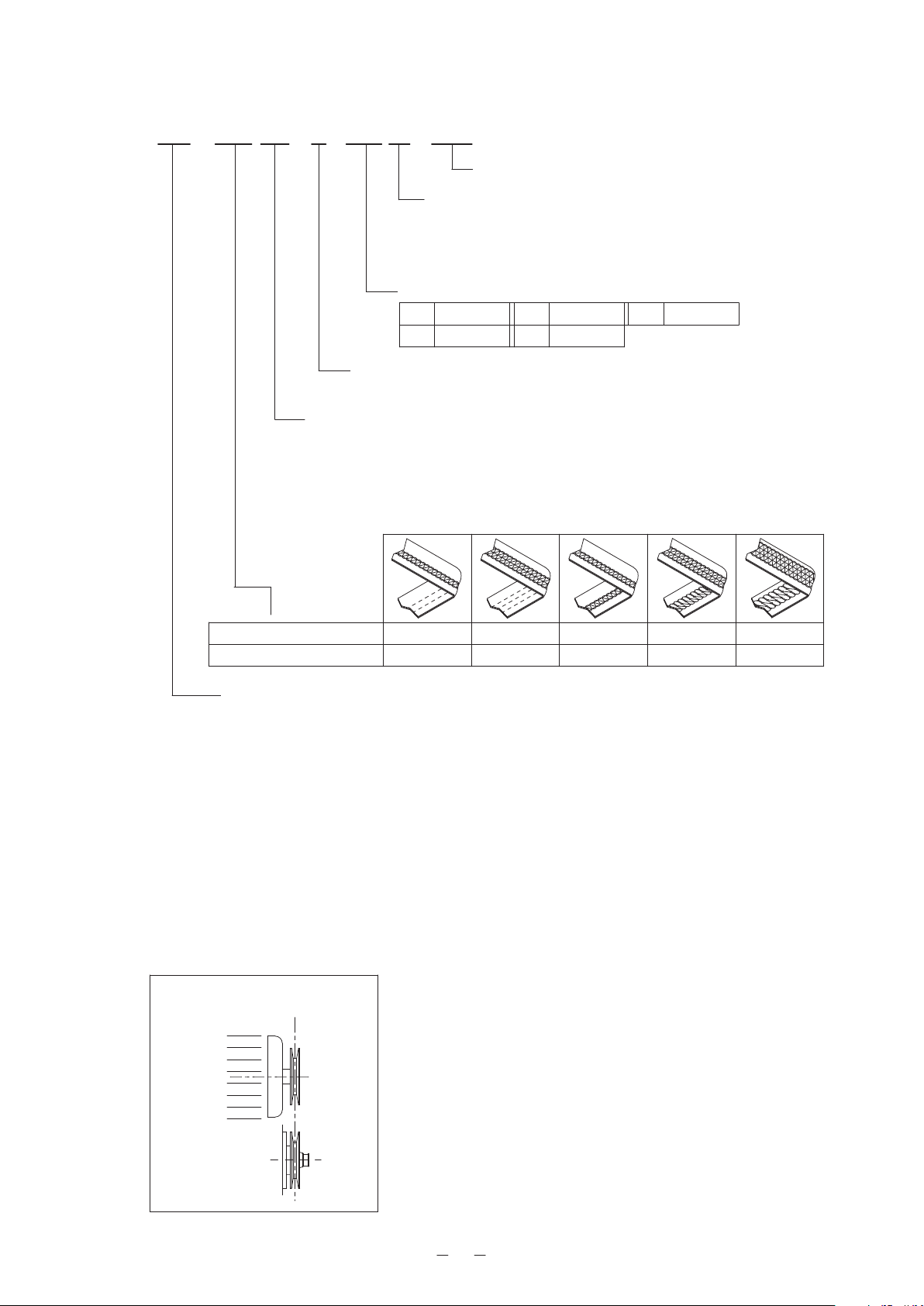

5. 與縫製有關的各項調整 PROPER OPRATION ADJUSTMENT

5-1 壓蛻ㄓO(圖 A ) PRESSURE OF PRESSER FOOT

5-2 縫線張力(圖 B ) THREAD TENSION

5-3 進給率調整(參考下表) ADJUSTING STITCH LENGTH

LOOSE TIGHT

右

左

圖 A

B圖

不同的縫線須要不同的張力,而相同的縫線穿在不同的位置,也對張力有

不同的需求,每條縫線都可透過張力調整組分別調整。

向右轉張力加大,向左轉張力減小。

在不影響縫製效果下,盡可能減小縫線的張力。

DIFFERENT THREADS HAVE DIFFERENT TENSIONS AND EVEN SAME THREADS

WILL HAVE DIFFERENT TENSIONS WHEN GO THROUGH DIFFERENT

THREADING HOLES.EACH THREAD TENSION CAN BE ADJUSTED BY INDIVDUAL

TENSION NUT TO INCREASE THREAD TENSION,TURN TENSION NUT CLOCKWISE,

TO DECREASE THREAD TENSION,TURN TENSION NUT COUNTERCLOCKWISE.PLEASE

USE LEAST THREAD TENSION AS LONG AS IT WILL NOT AFFECT THE SEWING EFFECTS.

STITCH LENGTH

本縫機進給率可調範圍從 1.4MM 每針到 3.6MM 每針,採用無段式變速。

ADJUSTMENT OF STITCH LENGTH CAN BE MADE STEPLESSLY FROM 1.4MM/PER STITCH TO 3.6MM/PER

STITCH.

下表列出進給率的參考值 THE TABLE BELOW SHOWS THE STITCH LENGTH.

STITCH NUMBER

STITCH NUMBER

每英吋相當的針數 每 30MM 相當的針數

3.6mm

1.4mm

2.4mm

7針 PER/英吋INCH

10.5針 PER/英吋INCH

18針 PER/英吋INCH

8針 PER/30MM

12.5針 PER/30MM

21針 PER/30MM

縫目

左

LOOSE

右

TIGHT

(A)

(B)