Version 3.1

Dieselstraße 17 · D-47228 Duisburg

Internet: www.kt-ow.de · e-mail: info@kt-ow.de

A. Kirchner & Tochter GmbH

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22

-2-

Contents

1 Foreword ................................................................................................................3

2 Safety .....................................................................................................................3

2.1 Symbol and meaning ....................................................................................3

2.2 General safety directions and exemption from liability..................................3

2.3 Intended use .................................................................................................4

2.4 Special safety instructions concerning glass devices ...................................4

2.5 Information for Operator and operating personnel ........................................4

2.6 Regulations and guidelines ...........................................................................4

2.7 Notice as required by the hazardous materials directive ..............................5

3 Transport and storage ............................................................................................5

4 Installation ..............................................................................................................6

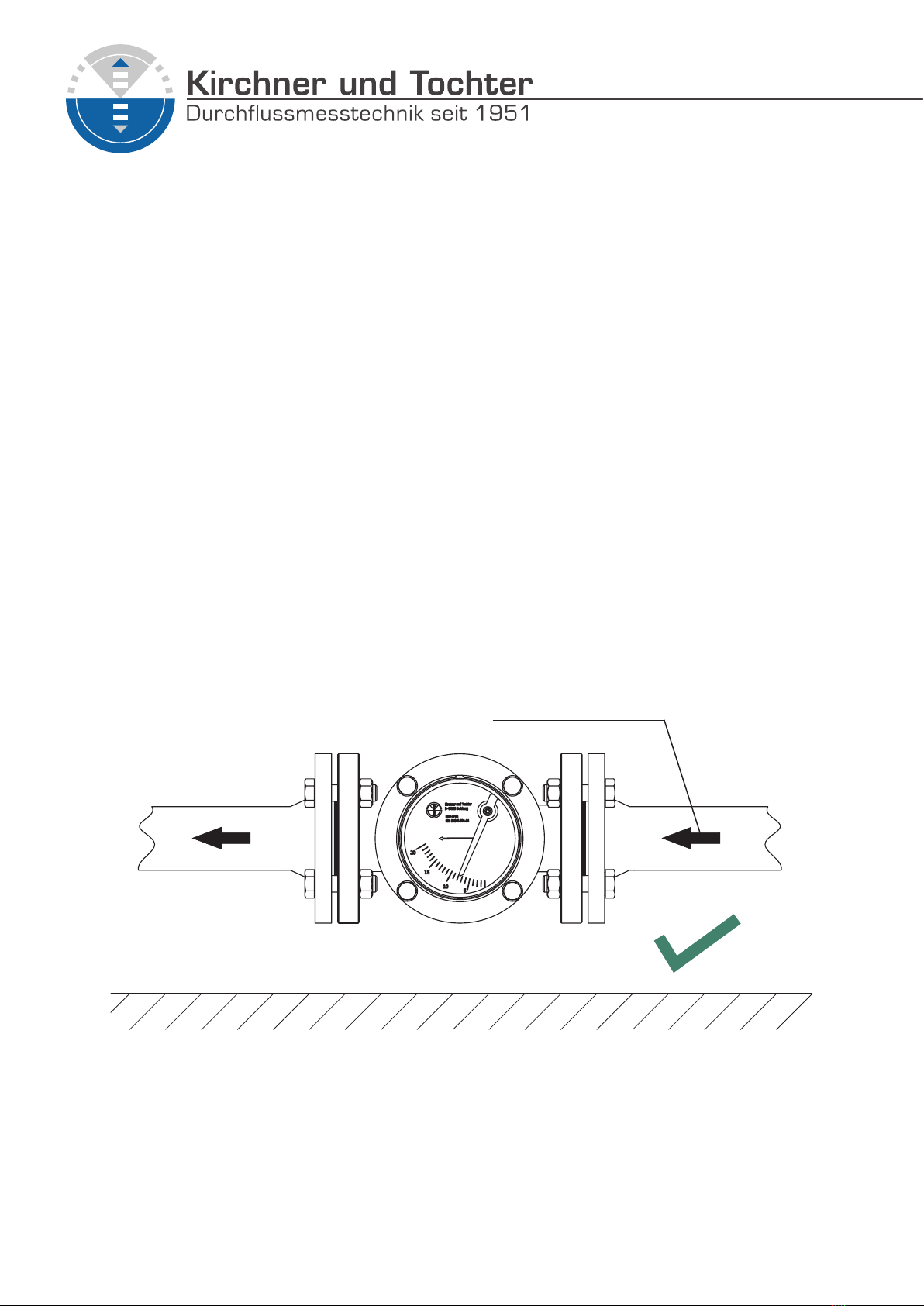

4.1 Mounting position KLA .................................................................................6

4.2 Installation KLA .............................................................................................7

5 Start-up ..................................................................................................................8

6 Readings in operation ............................................................................................8

7 Limit switches .........................................................................................................9

7.1 Connection of limit switches .........................................................................9

7.2 Setting the limit switches ............................................................................10

7.2.1 Preparation.....................................................................................10

7.2.2 Adjusting the limit switches ............................................................10

7.2.3 Adjusting the switching function .....................................................10

7.2.4 Installation of the polycarbonate protective screen ........................11

7.3 Replacing the limit switch............................................................................11

8 Analogue output EM .............................................................................................12

8.1 Functional principle .....................................................................................12

8.2 Connection ..................................................................................................12

9 Maintenance and cleaning of the low meter .........................................................13

10 Service .................................................................................................................13

10.1 Disposal ......................................................................................................13

11 Technical data ......................................................................................................14

11.1 Materials .....................................................................................................15

11.2 Measuring ranges .......................................................................................16

11.3 Dimensions and weights .............................................................................17

11.3.1 Flange connection acc. EN 1092-1 PN10 ......................................17

11.3.2 Flange connection acc. ASME B16.5 class 150lbs ........................18

11.4 Type series .................................................................................................19

11.5 Technical data of limit switches ..................................................................19

11.6 Analogue output EM ...................................................................................21