2

Introduction

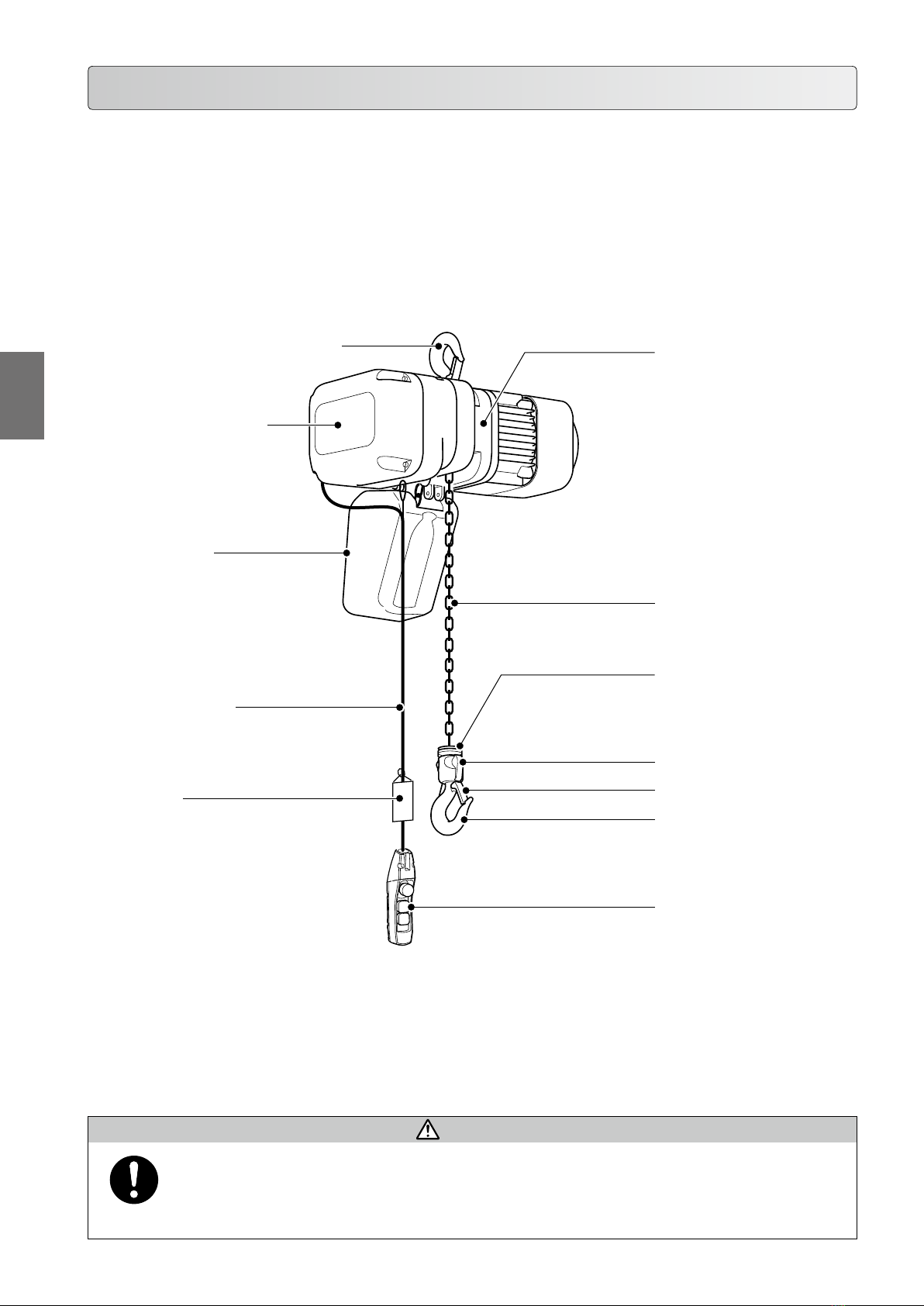

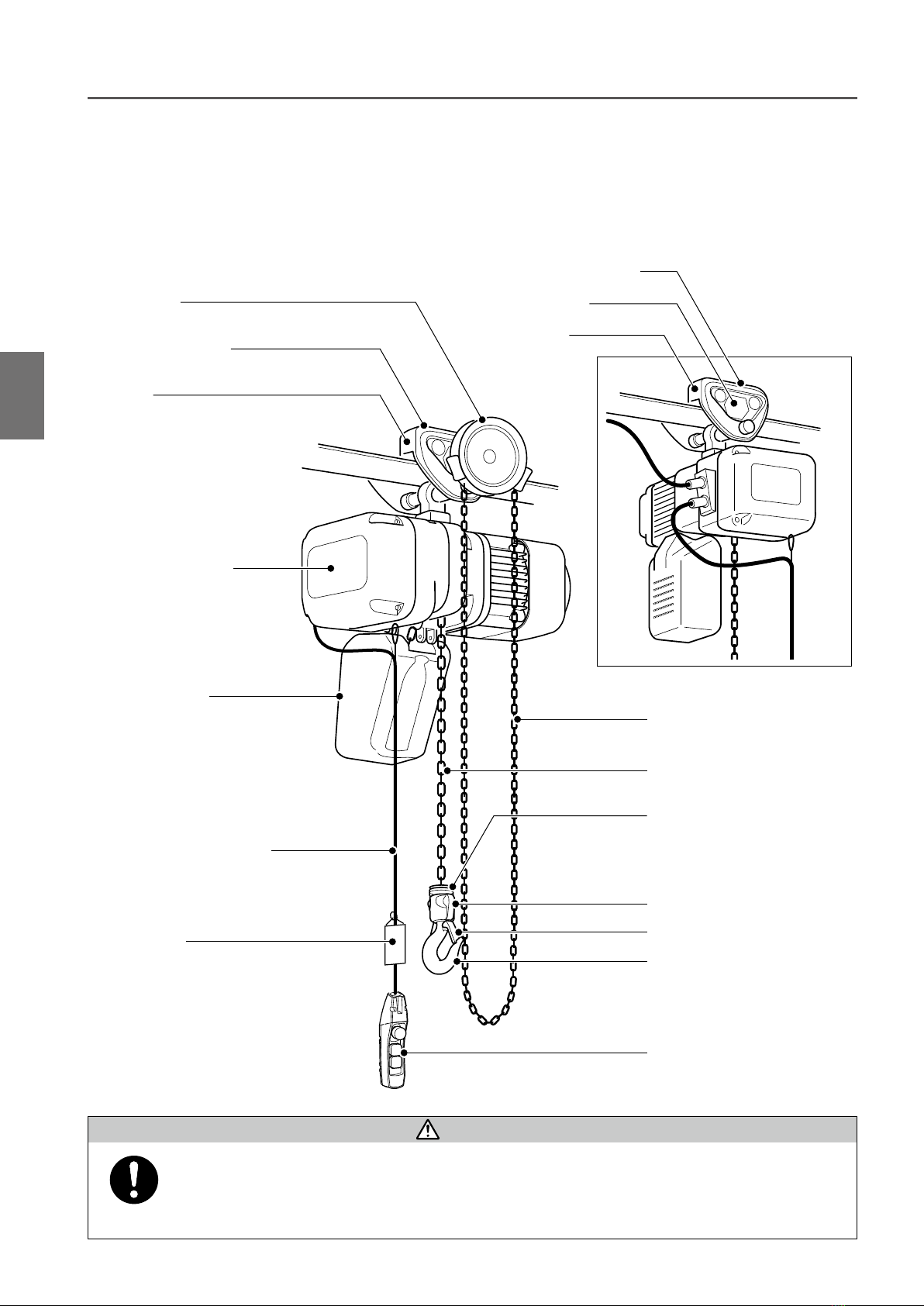

This electric hoist ER2 is designed and manufactured for the purpose to lift and lower a load within a normal

work environment. The motorized trolley MR2 and the manual trolley are designed and manufactured for the

purpose to move the lifted load laterally with the combination with the electric hoist.

Movement of a load in a 3D direction such as up/down, forward/backward and right/left is also enabled by

combining with a crane.

This Owner's Manual is intended for those operating the KITO electric hoist ER2 and maintenance engineers

(* pesonnel with expertise).

Other than this manual, Disassembly/Reassembly Manual and Parts List are also available for the maintenance

engineers. Assign the maintenance engineers and use these materials for inspection and repair. Please contact

the nearest distributor or KITO for these materials.

Introduction ............................................................................................2

Safety Precautions ................................................................................4

Chapter 1 Handling the Product ..........................................................7

Chapter 2 Inspection ..........................................................................63

Chapter 3 Troubleshooting ................................................................93

Appendix ............................................................................................119

Warranty .............................................................................................162

Table of Contents

■Disclaimer

●KITO shall not be liable for any damage incurred thereof due to natural disaster such as fire, earth quake

and thunderbolt, conduct by third party, accident, willful conduct or negligence by customer, erroneous use

and other use exceeding the operational condition.

●KITO shall not be liable for any incidental damage due to the use or non-use of the product such as the loss

of business profit, suspension of business and damage of the lifted load.

●KITO shall not be liable for any damage arising from negligence of the contents in the Owner's Manual and

the use of the product exceeding the scope of its specification.

●KITO shall not be liable for any damage arising from the malfunction due to the combination of the product

with other devices in which KITO is not concerned.

●KITO shall be indemnified from any loss of life, bodily injury and property damage due to the use of our

product for which it has passed 10 years since its delivery.

●KITO shall not be liable to supply the spare parts for the product for which it has passed for 15 years since

the discontinue of the product.