PCE Health and Fitness TU 3 User manual

PCE Americas Inc.

711 Commerce Way

Suite 8

Jupiter

FL-33458

USA

From outside US: +1

Tel: (561) 320-9162

Fax: (561) 320-9176

info@pce-americas.com

PCE Instruments UK Ltd.

Units 12/13

Southpoint Business Park

Ensign way

Hampshire / Southampton

United Kingdom, SO31 4RF

From outside UK: +44

Tel: (0) 2380 98703 0

Fax: (0) 2380 98703 9

info@pce-instruments.com

www.pce-instruments.com/english

www.pce-instruments.com

Manual

Shaft alignment tool PCE-TU 3

Version 1.0

Date of creation: 09.09.2015

Date of last change: 01.03.2016

Manual

2

Contents

1Introduction .............................................................................................................5

2Safety notes.............................................................................................................5

2.1 Precautions................................................................................................................................. 5

3Specifications..........................................................................................................6

4System description.................................................................................................7

4.1 Technical description.................................................................................................................. 7

4.2 Application.................................................................................................................................. 8

4.2.1 CE-Conformity................................................................................................................................ 8

4.3 Delivery content.......................................................................................................................... 8

4.4 Misalignment parameters........................................................................................................... 9

5Machine alignment................................................................................................10

5.1 Determination of measurement data........................................................................................ 10

5.2 System setup............................................................................................................................ 11

5.3 Connection of the measurement sensors................................................................................. 11

5.4 Entering of the dimensions....................................................................................................... 12

5.5 Rough alignment ...................................................................................................................... 14

5.5.1 Rough alignment (var. 1) ............................................................................................................. 14

6Commissioning .....................................................................................................15

6.1 General control keys................................................................................................................. 15

6.2 Starting the PCE-TU 3.............................................................................................................. 15

7Machine alignment................................................................................................16

7.1 Horizontal alignment................................................................................................................. 16

7.1.1 Enter dimensions ......................................................................................................................... 17

7.1.2 Change parameters ..................................................................................................................... 18

7.1.3 Data acquisition............................................................................................................................ 19

7.1.4 Result........................................................................................................................................... 23

7.1.5 Live Alignment.............................................................................................................................. 24

7.2 Vertical machine alignment ...................................................................................................... 28

7.2.1 Entry of machine dimension......................................................................................................... 29

7.2.2 Change/add parameters .............................................................................................................. 30

7.2.3 Data acquisition............................................................................................................................ 31

7.2.4 Result........................................................................................................................................... 36

7.3 Soft Foot Measurement............................................................................................................ 40

7.4 Drive Shaft Alignment............................................................................................................... 41

7.4.1 Set machine dimensions and measurement units....................................................................... 42

7.4.2 Change parameters ..................................................................................................................... 43

7.4.3 Collect data and align Proceed as in the horizontal machine alignment. Pay attention to the

following differences:.................................................................................................................................. 44

7.5 Alignment of machine trains..................................................................................................... 44

7.5.1 Short explanation......................................................................................................................... 44

7.5.2 Execution of a machine train alignment....................................................................................... 44

7.5.3 View measurement results........................................................................................................... 46

7.6 Spindle Program....................................................................................................................... 47

7.6.1 Main screen of the Spindle Program............................................................................................ 48

7.6.2 Measurement process.................................................................................................................. 48

7.6.3 Carry out measurement ............................................................................................................... 48

7.6.4 View and save results.................................................................................................................. 49

Manual

3

7.7 Plumbline Program................................................................................................................... 50

7.7.1 Short explanation......................................................................................................................... 50

7.7.2 Carry out Plumbline Measurement .............................................................................................. 51

7.7.3 Main screen of the program......................................................................................................... 51

7.7.4 Configuration process.................................................................................................................. 52

7.7.5 Screen overview........................................................................................................................... 52

7.7.6 Carry out measurements ............................................................................................................. 53

7.7.7 Duration of the connection establishment.................................................................................... 53

7.7.8 Display overview.......................................................................................................................... 54

7.7.9 View and save results.................................................................................................................. 54

8Extended alignment tools.....................................................................................57

8.1 Flatness Program ..................................................................................................................... 57

8.1.1 Short explanation......................................................................................................................... 57

8.1.2 Main screen of the program......................................................................................................... 57

8.1.3 Change parameters ..................................................................................................................... 58

8.1.4 Create or edit a rectangular grid .................................................................................................. 59

8.1.5 Create circular grid....................................................................................................................... 60

8.1.6 Edit the grid.................................................................................................................................. 60

8.1.7 Editing screen for rectangular grid............................................................................................... 61

8.1.8 Editing screen for circular grid ..................................................................................................... 62

8.1.9 Carry out measurement ............................................................................................................... 62

8.1.10 View and save results.................................................................................................................. 64

8.1.11 Reference modes......................................................................................................................... 64

8.1.12 Define reference points................................................................................................................ 65

8.1.13 Result modes ............................................................................................................................... 65

8.1.14 Enter tolerances........................................................................................................................... 66

8.1.15 View statistics............................................................................................................................... 66

8.2 Bores and centre line programme............................................................................................ 68

8.2.1 Short explanation......................................................................................................................... 68

8.2.2 Main screen of the program (configuration of planes and changing of parameters)................... 68

8.2.3 Configuration process.................................................................................................................. 69

8.2.4 Carry out measurement ............................................................................................................... 70

8.2.5 Duration of the connection establishment.................................................................................... 70

8.2.6 Carry out, view and replace measurements ................................................................................ 71

8.2.7 View and save results.................................................................................................................. 72

8.2.8 Live Mode..................................................................................................................................... 73

8.3 Straightness Program............................................................................................................... 74

8.3.1 Short explanation......................................................................................................................... 74

8.3.2 Carry out a straightness measurement........................................................................................ 74

8.3.3 Main screen of the program (configure positions and change parameters) ................................ 74

8.3.4 Screen overview........................................................................................................................... 75

8.3.5 Splice explanation........................................................................................................................ 75

8.3.6 Configuration process.................................................................................................................. 76

8.3.7 Carry out measurements ............................................................................................................. 76

8.3.8 Duration of the connection establishment.................................................................................... 76

8.3.9 Rough alignment of the laser beam............................................................................................. 77

8.3.10 Carry out, access and replace measurement.............................................................................. 78

8.3.11 View and save results.................................................................................................................. 78

8.3.12 Tutorial for the use of splices....................................................................................................... 80

8.3.13 Live Mode..................................................................................................................................... 80

8.4 Rectangularity program („Squareness programm“) ................................................................. 82

8.4.1 Main screen of the program......................................................................................................... 82

8.4.2 Measurement process.................................................................................................................. 82

8.4.3 Carry out measurement ............................................................................................................... 83

8.4.4 View and save results.................................................................................................................. 84

9System settings.....................................................................................................85

Manual

4

9.1 Set date and time ..................................................................................................................... 86

9.2 Configure automatic turn-off..................................................................................................... 87

9.3 View/set up program licences .................................................................................................. 88

9.4 Set data transfer of the sensor................................................................................................. 89

9.5 Set the user language .............................................................................................................. 90

9.6 Set USB-mode.......................................................................................................................... 91

10 Handling of the Data Dialogue window ...............................................................92

11 „My Documents“ option .......................................................................................94

11.1 Find/organize folders and files ................................................................................................. 94

11.2 Save a report as PDF file ......................................................................................................... 95

12 Appendix................................................................................................................96

13 Disposal.................................................................................................................97

14 Contact...................................................................................................................97

14.1 PCE Instruments UK ................................................................................................................ 97

14.2 PCE Americas .......................................................................................................................... 97

Manual

5

1 Introduction

Thank you for purchasing a Shaft alignment tool from PCE Instruments.

With the help of a Shaft alignment tool, you can perform shaft alignment on machines and motors quickly

and easily. For this purpose, the Shaft alignment tool possesses two special laser sensors, which are

fixed to the particular shaft. The Shaft alignment tool directly displays the corresponding correction values

for every machine base after a short measurement time. In addition to special programs for the alignment

of machines and motors, you can perform further geometrical measurements with the PCE-TU 3.

2 Safety notes

Please read this manual carefully and completely before you use the device for the first time. The device

may only be used by qualified personnel and repaired by PCE Instruments personnel. There is no

warranty of damages or injuries caused by non-observance of the manual.

This manual is published from PCE Instruments without any guarantee.

We expressly point to our general guarantee terms, they can be found in our general terms of business.

If you have any questions please contact PCE Instruments.

2.1 Precautions

The PCE-TU 3 is a class II laser system with a typical wavelength of 670 nm, < 1MW capacity and a

maximal radiation energy of 0,1 mJ per impulse. The class II laser meets the requirements according to

ANSI, BS 4803, IEC 825 and the US American FDA. Note the following safety notes to avoid injury and

damages on the device.

Caution:

- Do not ever directly look into the laser beam!

- Do not ever directly point the laser beam into anyone’s eyes!

Warning!

Make sure that the machines you measure are not started by accident, because injuries might occur. To

avoid that risk, you should either block the power switch in the OFF position or remove the corresponding

fuses. These security measures need to be maintained until the measuring system is removed from the

machines.

Disclaimer

Neither PCE Instruments, nor authorised salesmen can be blamed for damages on machines or working

tools that might occur in the process of working with the PCE-TU 3 system. We check the manual

carefully, to avoid possible errors. If you find an error in this manual, we would be very grateful, if you let

us know.

Manual

6

3 Specifications

Sensor type

Position sensitive photodiodes

Laser type

Visual, red 635 ... 670 nm, < 1 MW

Max. Distance

10 m between the sensors

Measurement accuracy

± 1 % + 0,001

Resolution

0,001 mm

Display resolution

0,01 or 0,001 mm

Inclinometer

Resolution 0,1 °

Interface

USB, Bluetooth

Memory

2 GB

Functions

Horizontal alignment in every position from 60 to

360°

Vertical alignment

Auto sweep mode

Adjustable tolerances

Tilt measurement

Thermal growth

Spacer simulation

PDF reports

Housing

With silicone protection

Protection type: IP65

Power supply

NiMH-Battery (rechargeable)

Environmental conditions

-10 ... +55 °C

Weight

7,5 kg

Manual

7

4 System description

4.1 Technical description

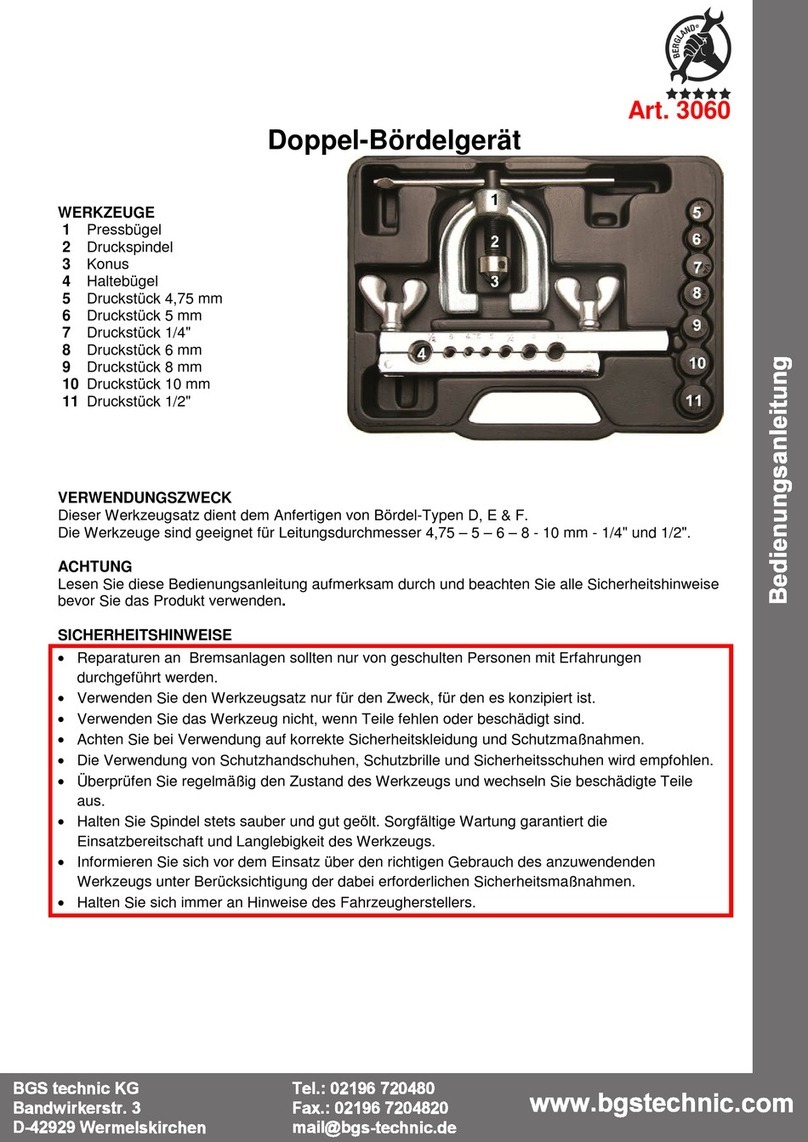

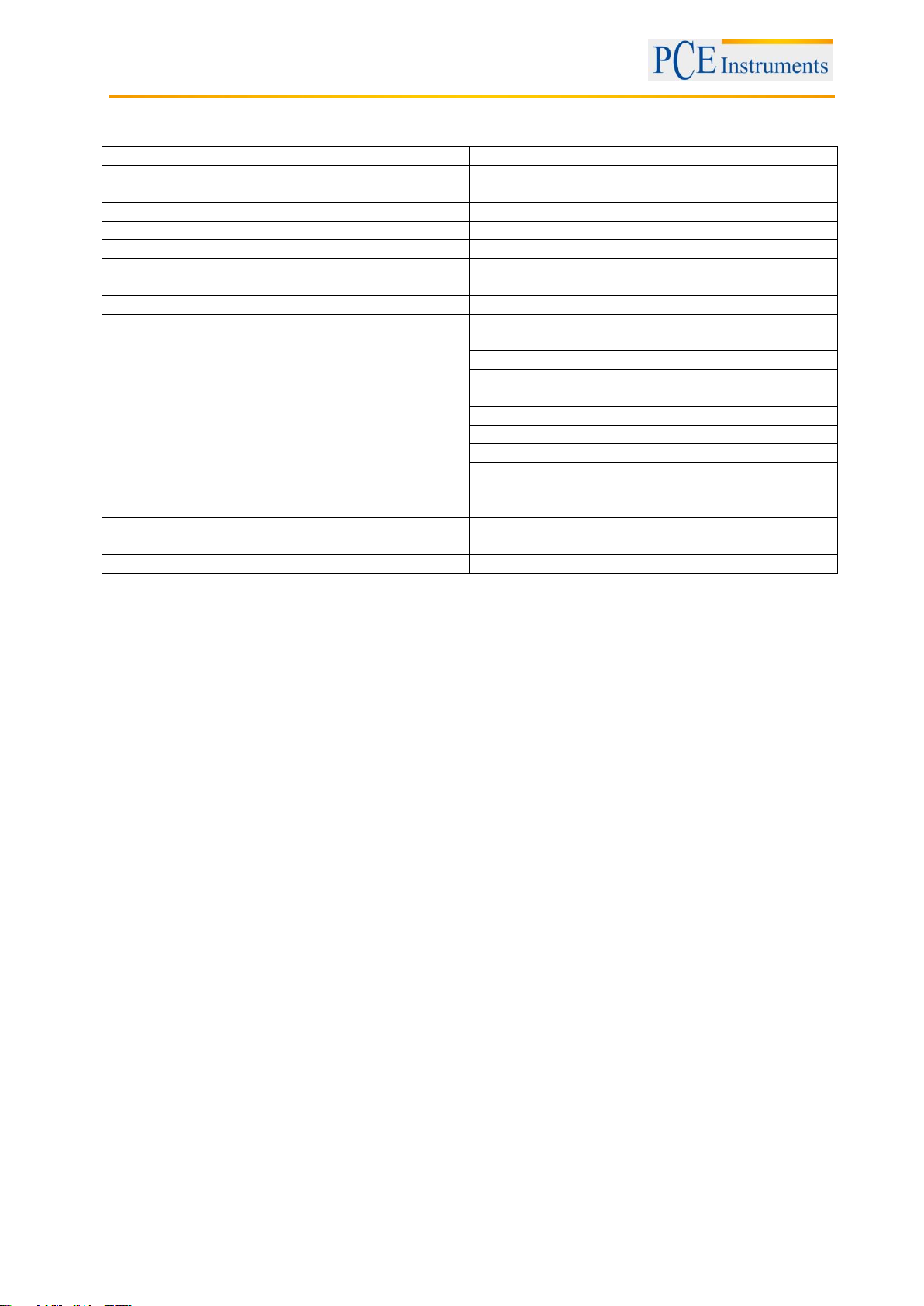

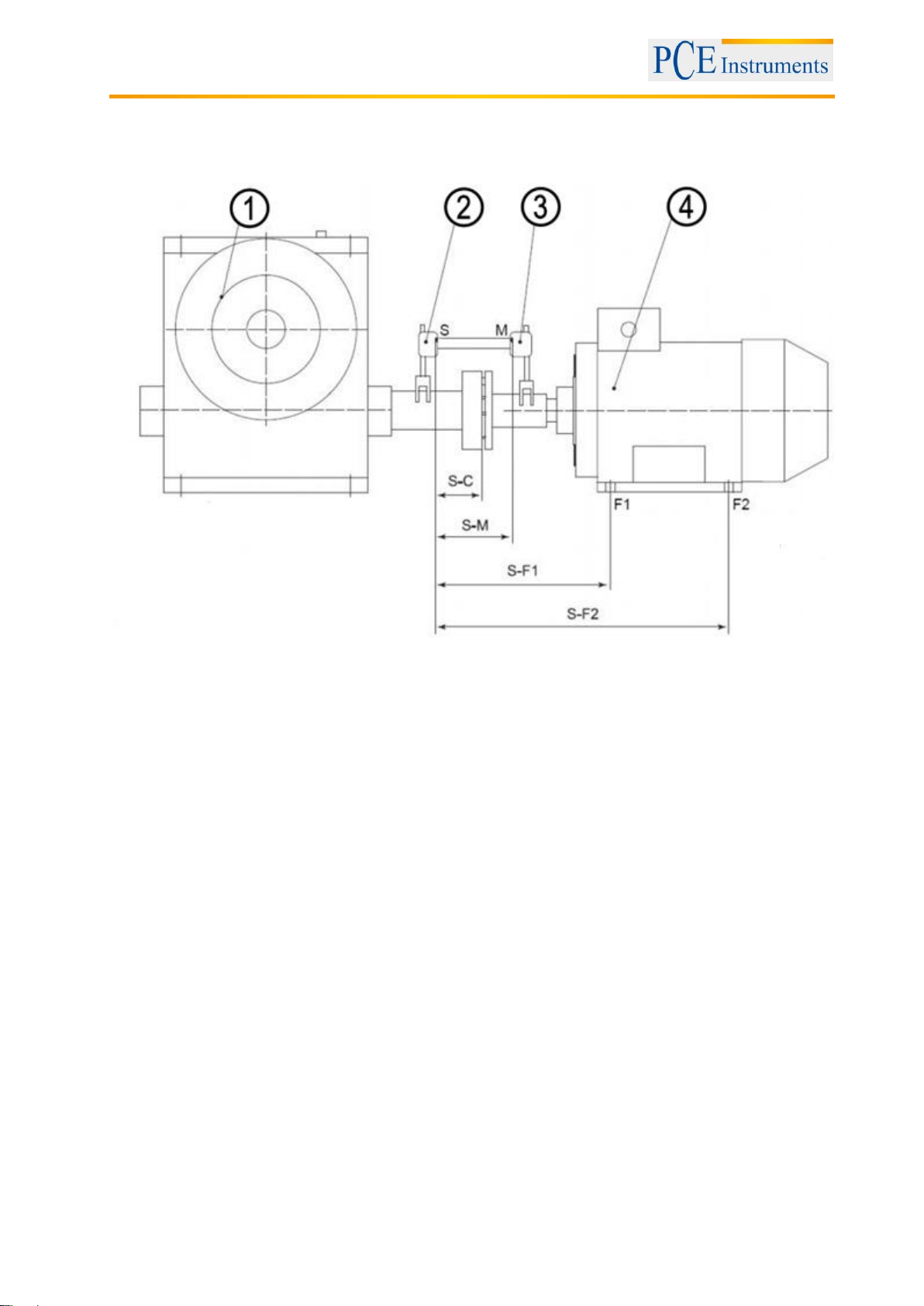

1

Lock button

2

Vertical alignment

3

Detector / target

4

Exit hole of the laser beam

5

Horizontal alignment

Front and top view of the measurement sensors

1

Reference point

2

Cable connector socket

Measurement sensor side view

1

Reference lines to measure the

sensor distance

Top view of the measurement sensors

Manual

8

4.2 Application

The Shaft alignment tool PCE-TU 3 was designed to check and optimize the shaft alignment between

machines. In order to do so, the relative position of two coupled machines (as for example a motor and a

pump) need to be changed, in order to make sure, that the centre lines of the shaft need to be concentric

during normal operation.

4.2.1 CE-Conformity

The Shaft alignment tool is conforming to the following CE requirements:

2006/95/EC, EN 61010-1:2001, EN 60825-1:2007, 2004/108/EC, EN 61326-1:2006, EN 61326-2-2:2006,

EN 55011:2009+A1

4.3 Delivery content

1 x PCE-TU 3 display unit, 2 x probes, 2 x mounting sets for the probes, 1 x measurement tape ,

1 x battery charger, 1 x connection cable, 1 x software, 1 x USB-cable, 1 x manual, 1 x carrying case

Manual

9

4.4 Misalignment parameters

Parallel misalignment

Angular misalignment

Parallel and angular misalignment (Offset + gap)

Parallel and angular misalignment can be determined in two rectangular planes. In order to eliminate

parallel and angular misalignment, the position of the moveable machine (M) needs to be adjusted in both

planes.

For horizontally mounted machines, the following needs to be applied:

The position of the moveable machine (M) needs to be aligned in the horizontal and vertical plane.

For vertically mounted machines, the following needs to be applied:

You need to discuss the use of the movement of a moveable machine under perspectives of operation

and efficiency with the machine operator. After that, you need to determine the arrangement of correction

planes.

Stationary machines (S): The position of the machine is not changed in the course of measurement

and elimination of parallel and angular misalignment

Moveable machines (M): The position of the machine is adjusted, in order to eliminate parallel and

angular misalignment

The measurement system determines the values for parallel and angular misalignment in the coupling (in

two rectangular planes) and the corrective values which are necessary for the elimination of

misalignments of the machine bases of the moveable machine (M). The following figure shows the

misalignment and corrective values for the vertical plane.

Misalignment (vertical plane)

1

Parallel misalignment (Offset)

2

Angular misalignment

3

Corrective value

S

Stationary machine

M

Moveable machine

Manual

10

5 Machine alignment

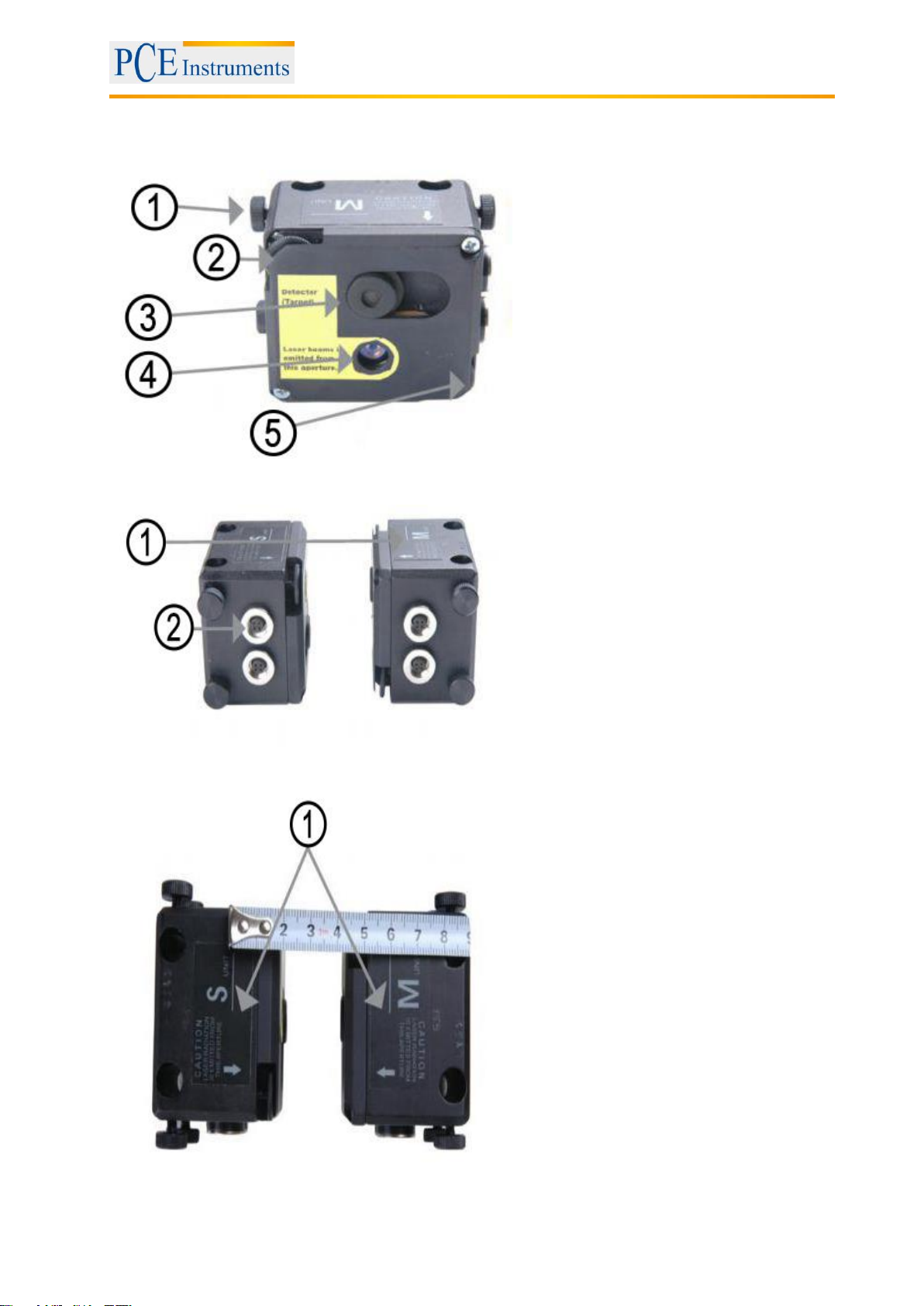

Mount the measurement sensors to the shaft of both machines, (S) and (M)

Select the corresponding measurement program

Enter the distance between sensor (S) and sensor (M) and between the coupling and the

machine base.

Press , in order to collect measurements on three different positions of the shaft

Adjust the position of the machine bases of the moveable machine according to the determined

measurement results.

Caution!

For the implementation of the measurement, it is important to conform to the rotation direction of the

shafts and to the relative position of the sensors to the machines (S) and (M).

The figure above, shows machine (S) from the point of view of machine (M) from 12 o’clock position. The

surfaces of the measurement sensors are marked as S and Mand should be mounted to the

corresponding shaft of the machine.

5.1 Determination of measurement data

The Shaft alignment tool PCE-TU 3 is based on the measurement of a moving laser beam in the target

window of the receiving sensor while the shaft, the sensor is mounted to, is rotated.

In order to determinate the axis alignment, at least three measurements (on different positions during the

rotation of the shaft) need to be carried out. A rotation of about 180 ° is sufficient here.

If a rotation of 180 ° should not be possible due to restricted spaces or an unfavourable arrangement of

the machines, the PCE-TU 3 supports a mode for smaller rotation angles. Total rotations of 60 ° are

sufficient in this mode.

Manual

11

5.2 System setup

Before working with the Shaft alignment tool, you need to control the battery status, and recharge the

battery, if necessary.

The battery status is displayed as a small, coloured figure on the bottom of the main menu of the

instrument, while the exact battery status is available in the menu item “Setup”.

Check and clean the surface of the laser detector and the exit hole of the sensor, if necessary.

Use a cotton pad soaked in alcohol for the cleaning. Do not use solvents for the cleaning under any

circumstances.

Check date and time of the system clock and adjust them, if necessary.

5.3 Connection of the measurement sensors

There are serial ports on the display unit, as well as on the measurement sensors. The sensors need to

be connected in series to the display unit with the enclosed cables. Refer to the following figure

Serial connection of the sensors

Manual

12

5.4 Entering of the dimensions

To achieve probable measurement results, you need to enter the distances between the sensors, the

coupling and the machine bases first. The following figures show the required dimensions for both,

horizontally and vertically mounted machines.

Horizontal alignment

1

Stationary machine

2

Sensor S

3

Sensor M

4

Moveable machine

F1

Front machine base

F2

Rear machine base

S-M

distance between the measurement sensors

S-C

distance between sensor S and the middle of the coupling

S-F1

distance between sensor S and the machine base F1

S-F2

distance between sensor S and the machine base F2 (needs to be larger than S-F1). If

the machine has three pairs of machine bases, the value can be adjusted after the

measurement. After a new measurement, you receive the corrective values for the third

pair of machine base.

Manual

13

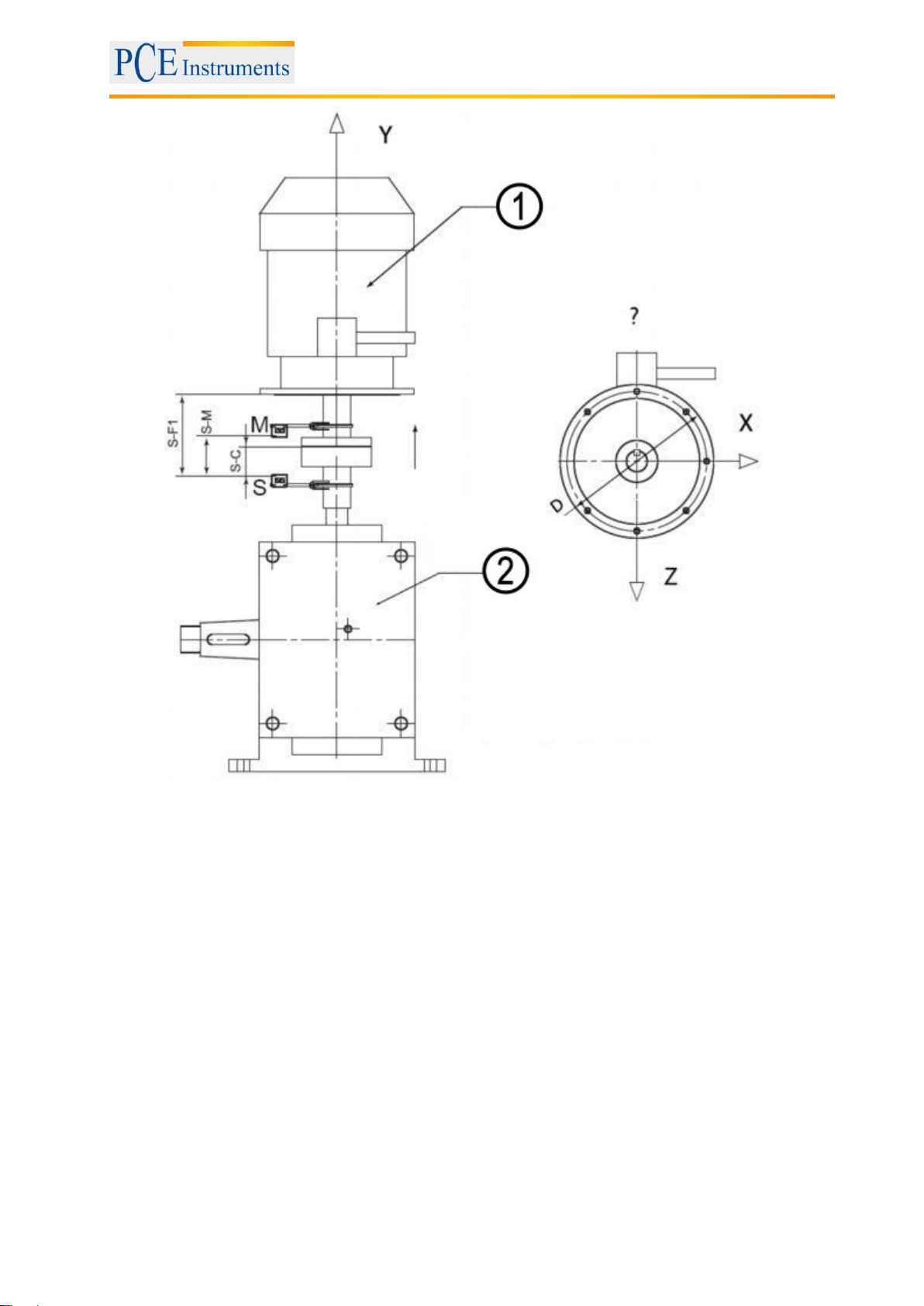

Vertical alignment

1

Moveable machine

2

Stationary machine

S-M

distance between the measurement sensors

S-C

distance between sensor S and the middle of the coupling

S-F1

distance between sensor S and the alignment plane F1

Manual

14

5.5 Rough alignment

Rough alignment should only be applied, if the axis alignment of the machines is in such a bad condition,

that the laser beams do not meet the detector during the rotation of the shaft anymore.

5.5.1 Rough alignment (var. 1)

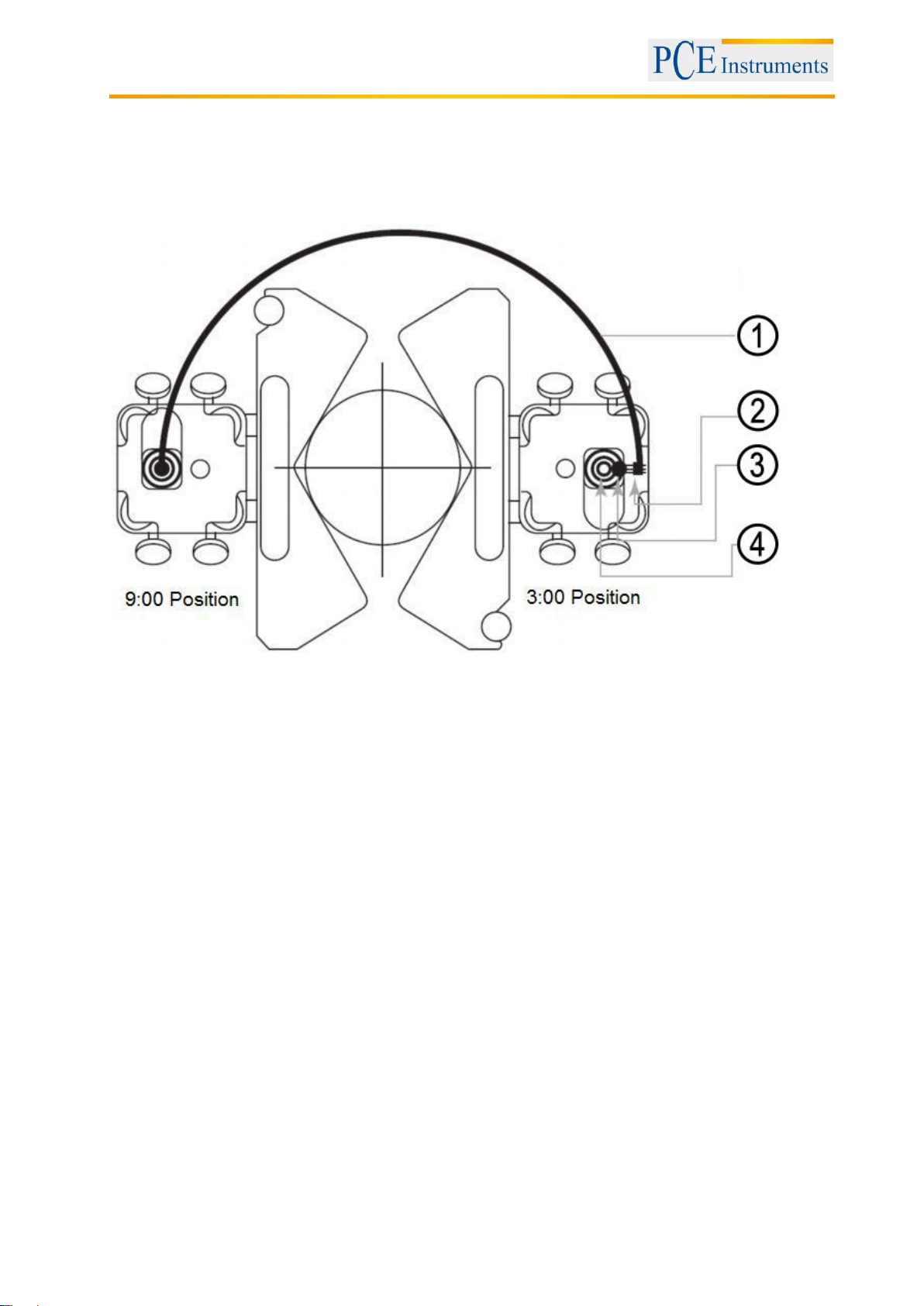

View from Sensor S

1

Route of the laser beam during the rotation of the shaft

2

Laser beam outside the detector area.

3

Fixing of the laser beam halfway of the route to middle of the detector

4

Alignment of the moveable machine (M), in order to make sure the laser beams meet

(S) and (M) in the middle.

Rotate the shaft with the measurement sensors to the 9:00 position. Aim the middle of the closed

detector opening.

Rotate the shaft with the measurement sensors to the 3 o’clock position.

Check, where the laser beams meet and use the adjustment screws to fix the laser beam in the

middle of the route, to the middle of the detector (figure view from sensor).

Now align the moveable machine to the position, where the laser beam meets S and M from.

Continue with your regular measurement procedure.

Manual

15

6 Commissioning

6.1 General control keys

To close all active windows –except for the main menu –without saving, you can push the button

(serves as ESC button).

The button serves to confirm or leave entering fields and active windows (except for windows with

data entry, main screens of programs and some other).

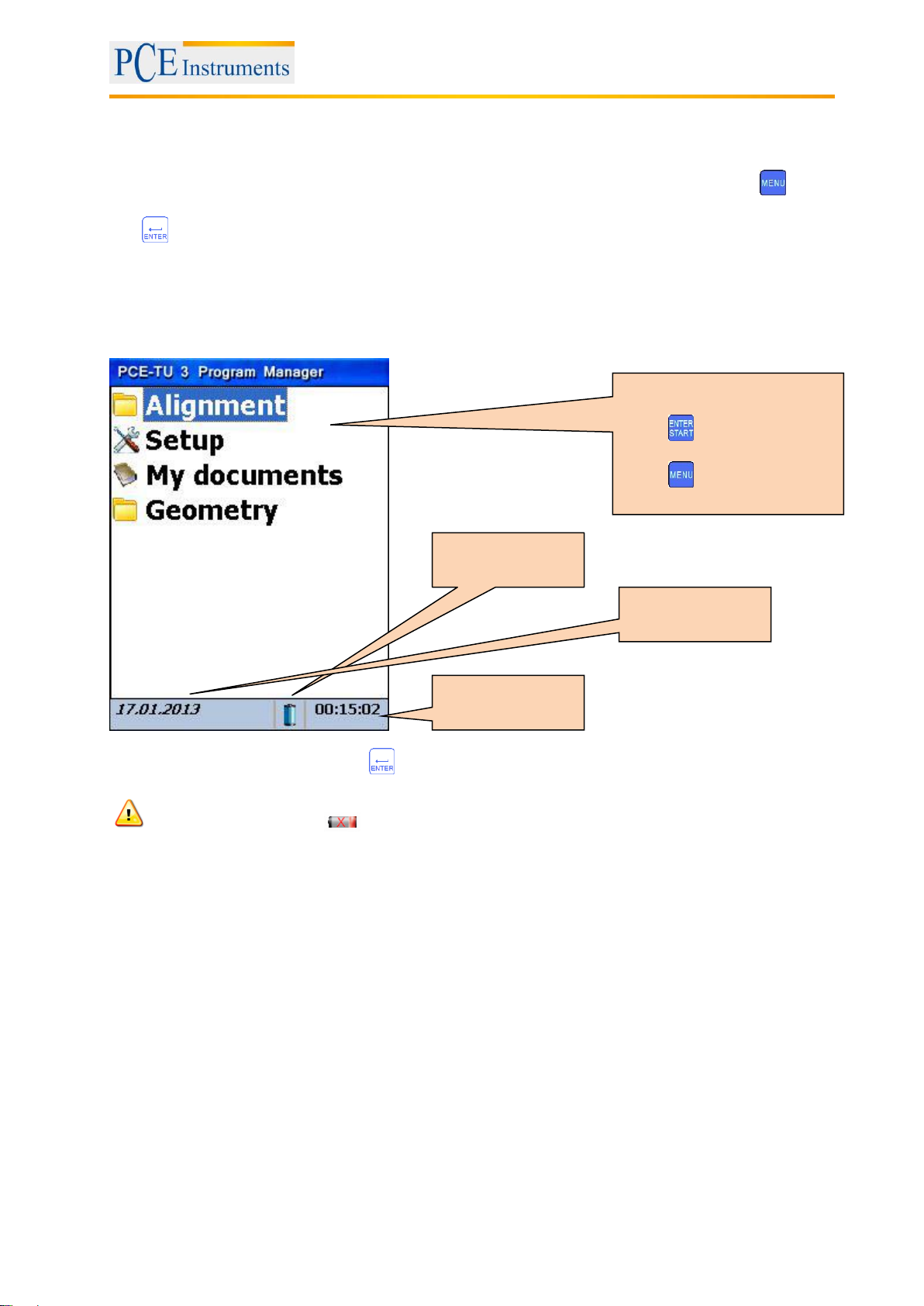

6.2 Starting the PCE-TU 3

Having completed the booting, the main menu appears on the display.

To select a menu item, press

if the battery indication is flashing, you should immediately save all unsaved data and recharge

the batteries. The symbol indicates that the instrument will turn off soon.

Main Menu items

Press , to open up a list of

subfolders.

Press to close this list.

Battery indicator

System time

System date

Manual

16

7 Machine alignment

7.1 Horizontal alignment

Mount the measurement sensor, marked as S, to the shaft of the stationary machine and the

measurement sensor, marked as M, to the moveable machine. Connect the cable (described in 3.3) to

the sensors and the main unit or configure the Bluetooth interface (only possible with the Bluetooth

adaptor kit).

What should be noted in this window

Shortcuts in this window

Firstly carry out the Soft Foot Measurement

to avoid unexpected errors during the alignment

check the result after alignment by

measurement again

determination of new data

Functions in this window

Continue alignment

- Determine new data

- Continue alignment

- Change of parameters

- Change machine dimensions and

distances

Change machine dimensions and

distances

Change/add parameters

Short description of

the active parameters

Manual

17

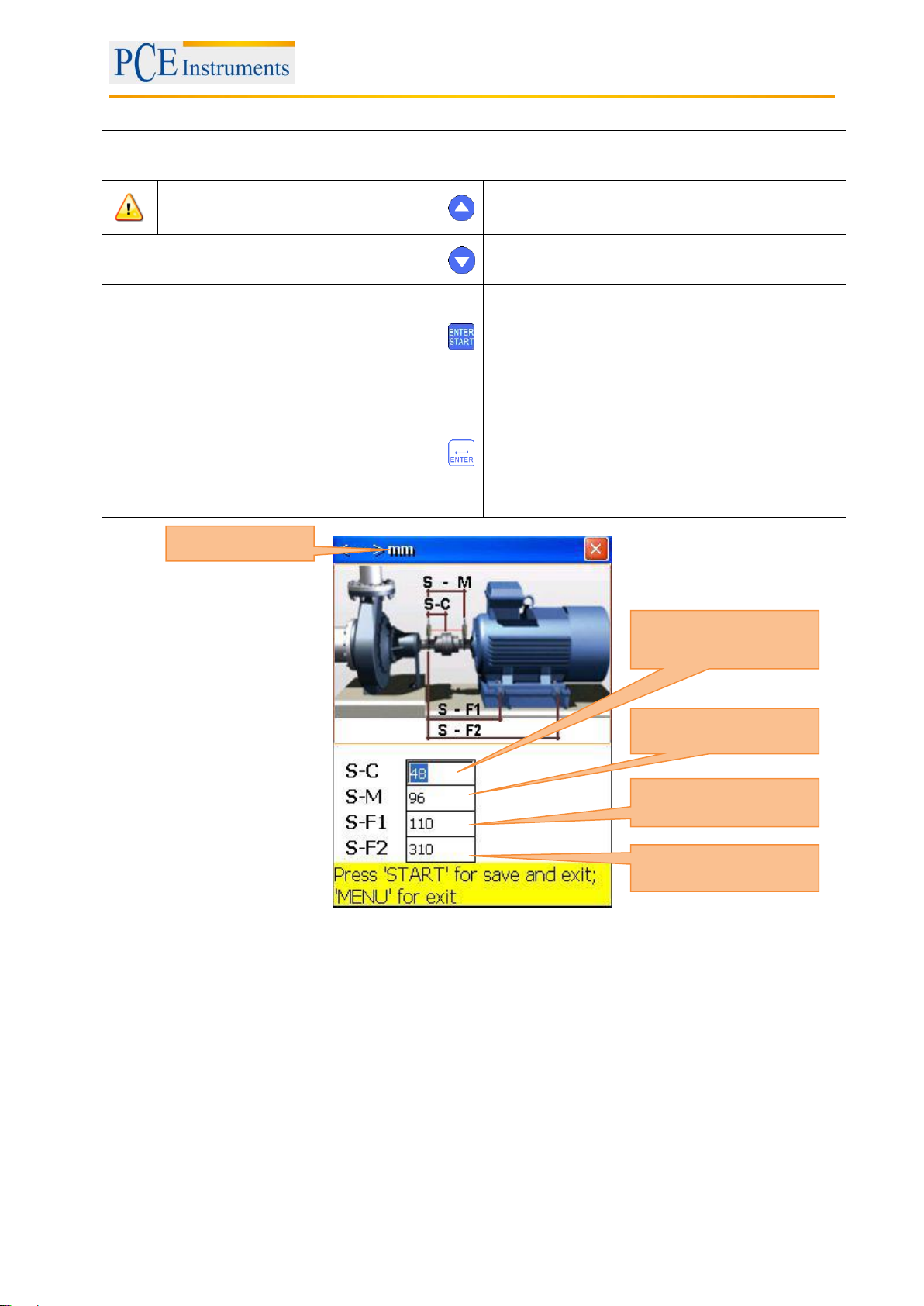

7.1.1 Enter dimensions

What should be noted in this window

Shortcuts in this window

for correct measurement results, the

following must be respected:

S-C ≤ S-F1 < S-F2

Navigate up

Functions in this window

Navigate down

- Enter distance sensor S –middle of

the coupling

- Enter distance sensor S –sensor M

- Enter distance sensor S –middle of

the coupling

- Enter distance sensor S –front

machine base

- Enter distance sensor S –rear

machine base

Save and leave and exit

Confirm entry

Measurement unit

Sensor S to middle of

the coupling

Sensor S to Sensor M

Sensor S to front

machine base

Sensor S to rear

machine base

Manual

18

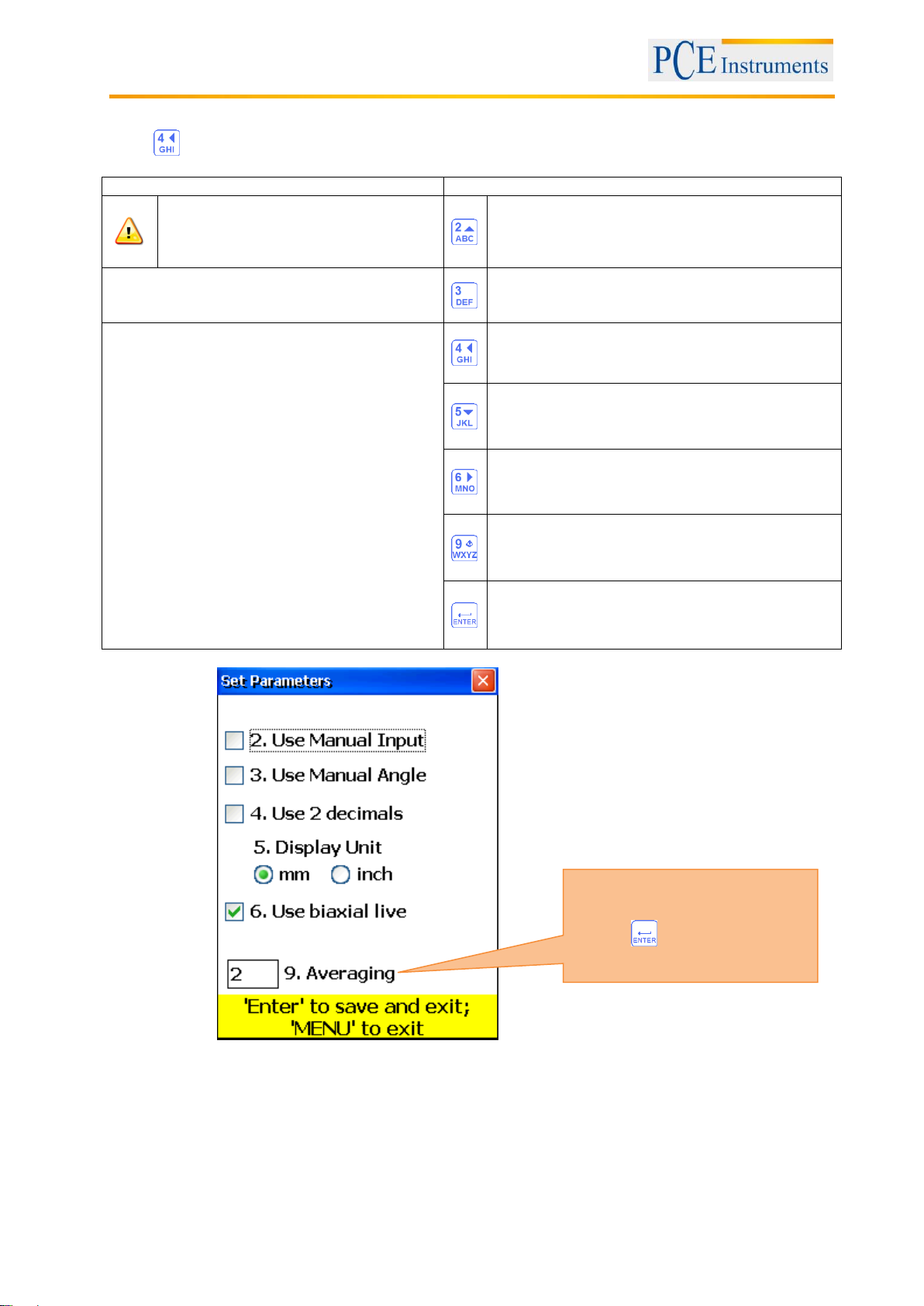

7.1.2 Change parameters

Press to change the parameters.

What should be noted in this window

Shortcuts in this window

Only use the “Biaxial Live”alignment

function with stable shaft positions,

because the smallest rotations can

lead to errors

Activate/deactivate manual data entry

Functions in this window

Activate/deactivate manual angle entry

- Manual entry or use of the sensor data

- Manual angle entry or data from

integrated inclinometer

- Selection between 2 or 3 decimal digits

- Selection between Inc and mm as

measurement unit

- Activate/deactivate “Biaxial Live”

alignment function

Use 2 or 3 decimal digits

Select between Inch and mm as measurement

unit

Activate/deactivate Biaxial Live alignment

Entry for averaging

Save and exit

Filter (averaging) settings

Press to confirm the entry

Manual

19

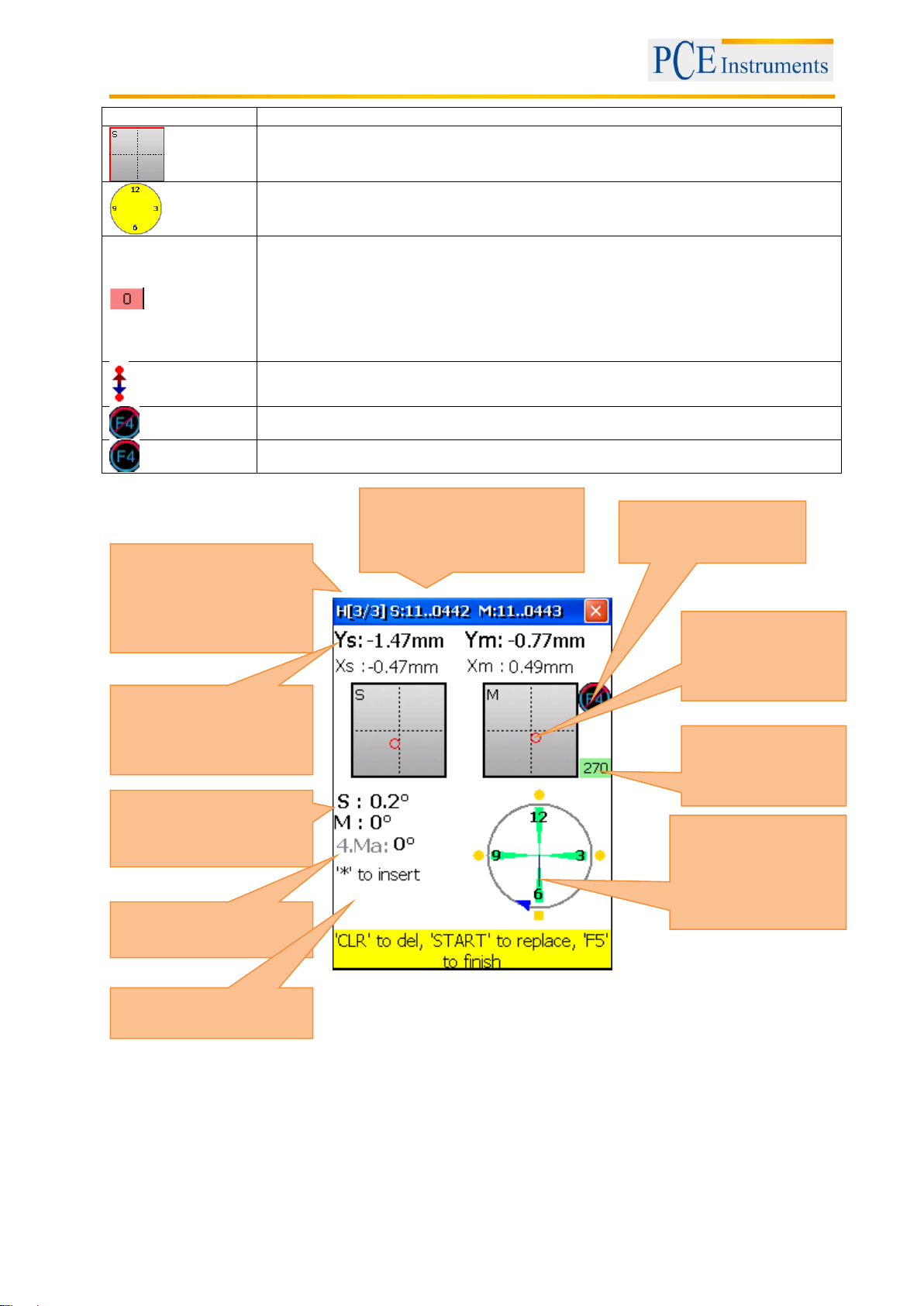

7.1.3 Data acquisition

Push to collect data.

What should be noted in this window

Shortcuts in this window

Before starting a new alignment

process, you need to enter dimensions

and parameters

Start again (deletes all values)

Confirmation dialogue appears

Do not change the position of

measurement units when work is

interrupted

Laser is now switched on

Functions in this window

Enter Ys-values, if manual entry is activated

- Collect measured values (up to 36)

- Select between auto sweep and

manual mode

- Manual entry of Ys- and Ym-values (if

activated)

- Manual angle entry (if activated)

- Selection of measurement unit

(mm/inch)

- Navigate through collected data

- Delete/add/replace measured values

- Restart (all values are deleted)

- Set Offset

- Save collected data

- Load collected data

Enter Ym-values, if manual entry is

activated

Enter angle, if manual entry is activated

If cursor is on the first place in the entry

field, push this button twice to reverse sign

Select the measurement unit (mm or inch)

Set parallel misalignment (Offset)

Save all data in one file (see chapter 10

„Handling of the Data Dialogue window“)

Load data from file (see chapter 10

„Handling of the Data Dialogue window“)

Delete currently selected reading

Enter new value. You have to switch to the

last value saved, to make this option

possible

Save the current value or replace already

saved values

(confirmation dialogue appears)

Navigate through data

Continue to the result window. All necessary

conditions need to be fulfilled

Open popup menu

Activate/deactivate auto-sweep. Auto-

sweep can only be activated at the

beginning of data acquisition or after restart.

Manual entry of values and inclination need

to be deactivated

Symbols and status in this window

[C]

A blinking amber-coloured “C” in the display means that currently no data can be

received from the sensors.

[R]

A blinking red “R” in the display means that you are already viewing a stored

reading. This one can be deleted or replaced. If this sign is not displayed in the

window, the current value has not been saved yet. Pressing , you can store

Manual

20

the value.

The absence of the laser beam position indicator and a red blinking frame of the

position indicator mean, that no laser beam meets arrives or no sensor data are

recognized.

An empty dial means that there is currently no angle established (or averaging is

not completed ) or that the rotation angle (to the next position) is too small (lower

than 6°)

A bright red indication means that the rotation angle does not meet the

requirements of the single measurement points (at least 60°).

A yellow indictaion means that the rotation angle is over 60°.

A green indication means that the rotation angle is over the recommended area

(over 90°).

This symbol means that an expanded Y-value range is used.

A crossed-out symbol means that the auto-sweep mode is deactivated.

This symbol means that the auto-sweep mode is activated.

Serial number of the

sensors. “No sensor”, if no

data can be received

Current

measurement/number of

measurements

Alignment type

H- horizontal

V - vertical

Angle of stationary and

moveable side

Manual angle

Note-Box

Dial with

measurement points

and the graphically

displayed angles

Entire rotation

angle; needs to be

larger than 60°

Laser beam position

indication

Auto-Sweep status

Table of contents

Languages: