Klaxon TCC-00 Series Manual

Other Klaxon Security System manuals

Klaxon

Klaxon Nexus 120 AC User manual

Klaxon

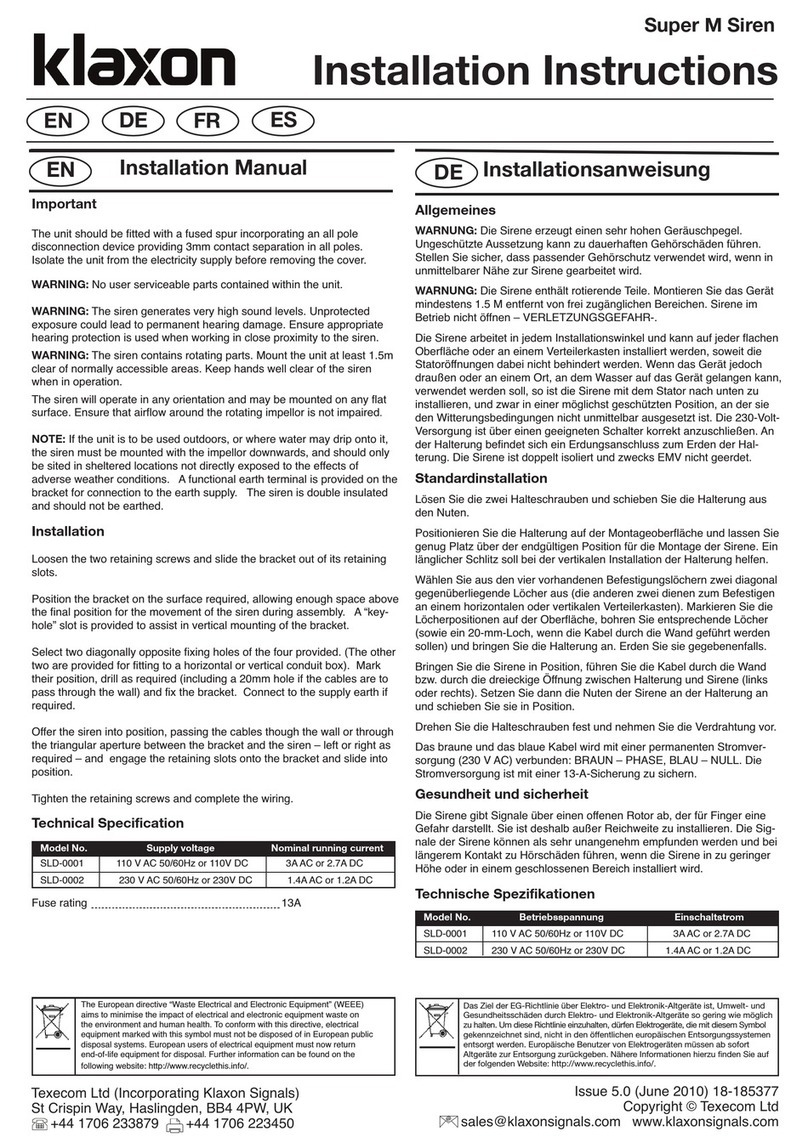

Klaxon Super M User manual

Klaxon

Klaxon Nexus AC Sounder & Sounder-Beacon User manual

Klaxon

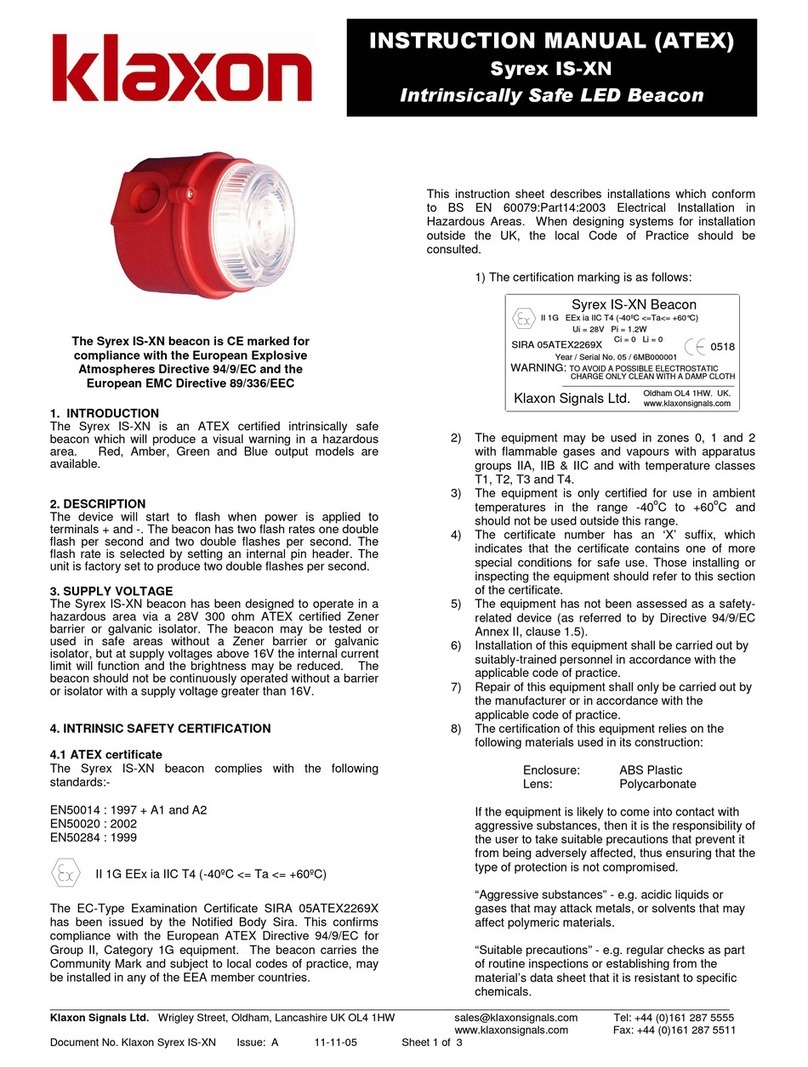

Klaxon Syrex IS-XN User manual

Klaxon

Klaxon GP10 Instruction Manual

Klaxon

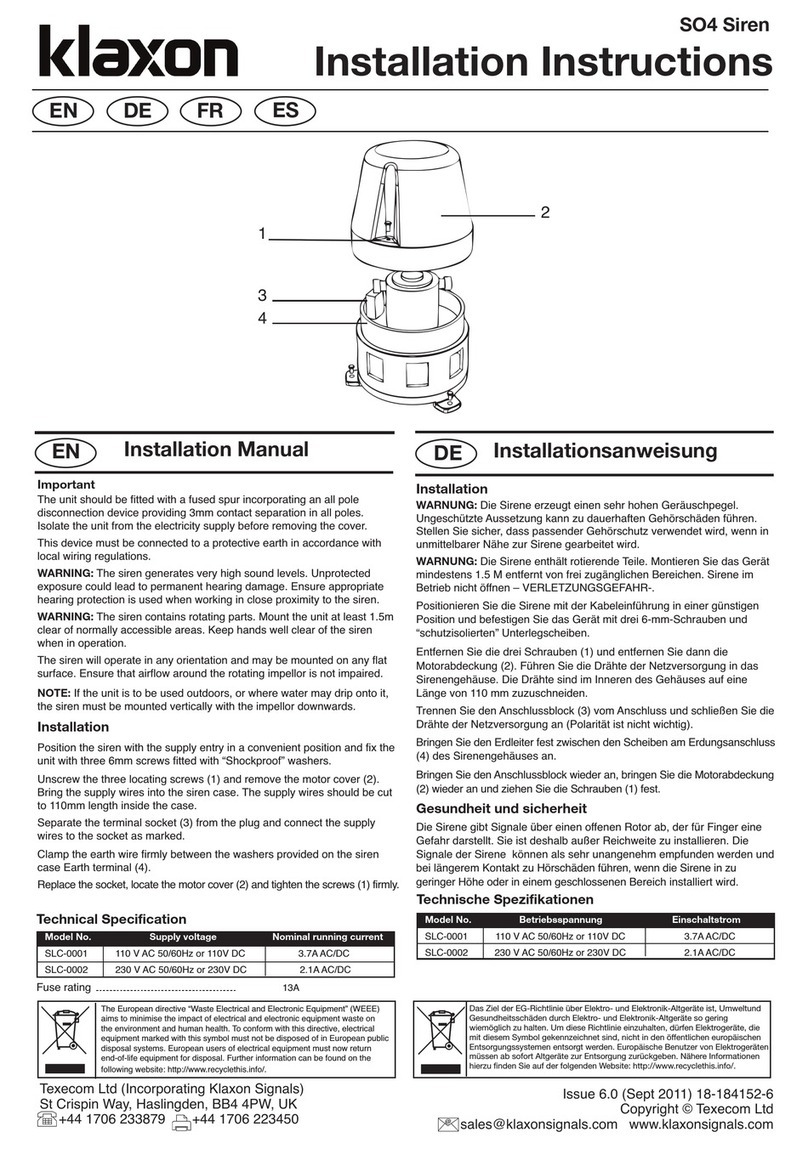

Klaxon SO4 Series User manual

Klaxon

Klaxon SLD-0001 User manual

Klaxon

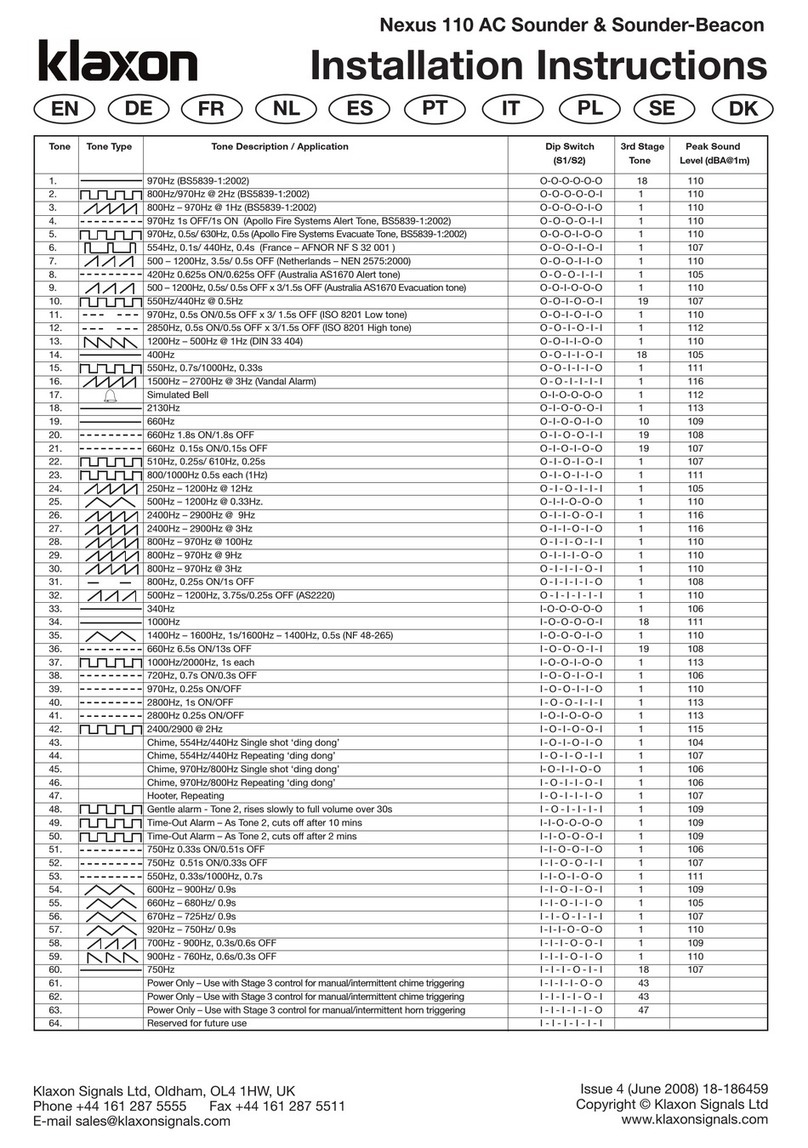

Klaxon Nexus 110 AC User manual

Klaxon

Klaxon Flashguard Minn-X User manual

Klaxon

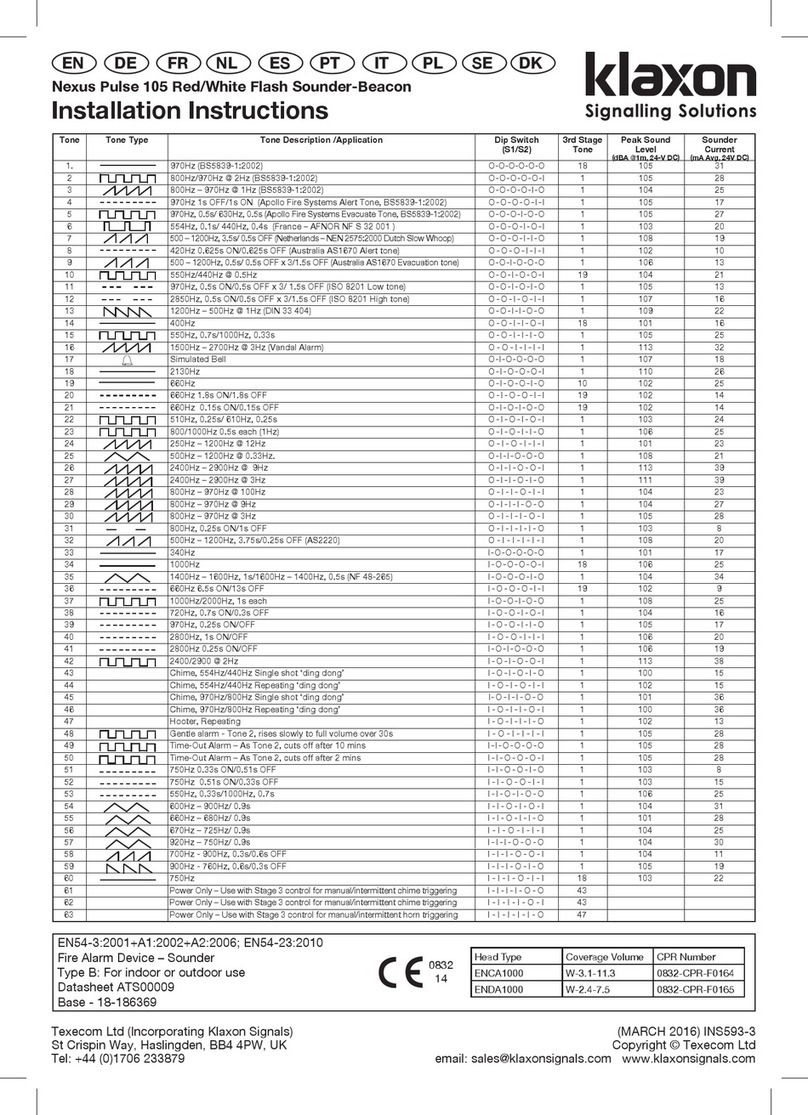

Klaxon Nexus Pulse 105 Red User manual

Popular Security System manuals by other brands

Secure

Secure USAB-1 operating instructions

B&B

B&B 480 SERIES Operation & maintenance manual

ADEMCO

ADEMCO VISTA-20P Series Installation and setup guide

Inner Range

Inner Range Concept 2000 user manual

Johnson Controls

Johnson Controls PENN Connected PC10 Install and Commissioning Guide

Aeotec

Aeotec Siren Gen5 quick start guide