11.11.2016

Page

11.11.2016

1 EC Declaration of Conformity ............ 5

2 Examination ........................................ 6

2.1 Examination by machine operator ........... 6

2.2 Periodic inspection ................................... 6

3 General information ...........................

.1 Information regarding the operating

manual ................................................. 7

4 Division ................................................

4.1 Keep a copy of the manual ...................... 7

4.2 Accessories .............................................. 7

5 Technical data ..................................... 8

5.1 General information ................................. 8

5.2 Power connection .................................... 8

5. Operating conditions ................................ 9

5.4 Power values ........................................... 9

5.5 Sound power level ................................... 9

5.6 Vibrations ................................................. 9

6 Indicator light, time and setting data10

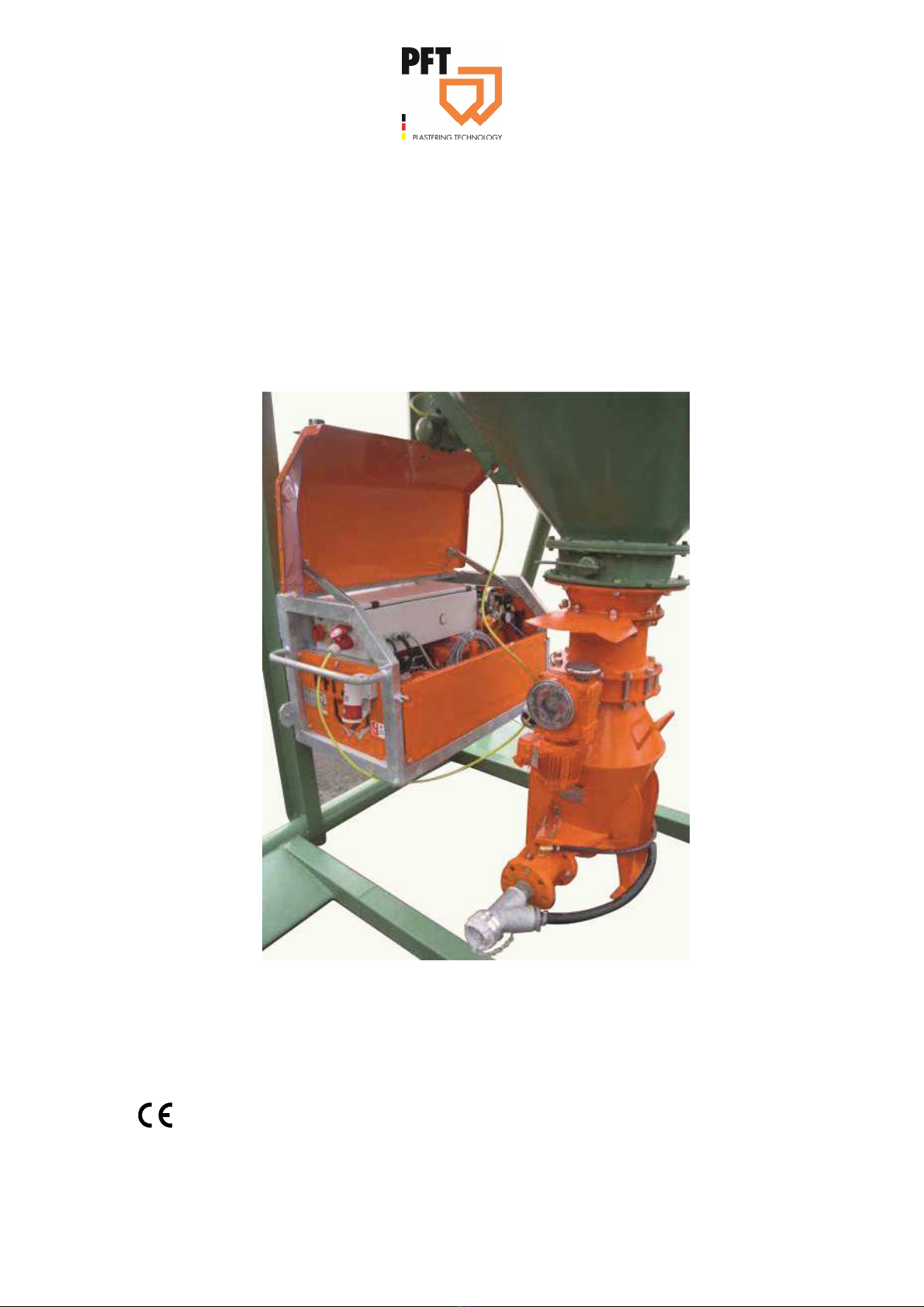

Assembly SILOJET III XXL ............... 11

7.1 Overview of the assembly units ............. 11

7.2 Frame with built-in parts ........................ 12

7. SILOJET III XXL pressure control.......... 1

7.4 Control cabinet and connections ........... 14

7.5 SILOJET III XXL carrier ......................... 15

8 Brief description ............................... 15

8.1 Conveying programme / work flow after

restart ................................................. 16

8.2 Conveying programme / work flow when

system is on standby ......................... 16

8. Intended purpose ................................... 17

9 Transport, packing and storage ...... 1

9.1 Safety instructions for transport ............. 17

9.2 Transport ................................................ 18

9. Transport inspection .............................. 18

9.4 Packaging .............................................. 19

9.5 Safety ..................................................... 19

10 SILOJET preparations .................... 20

10.1 Connecting the power supply .............. 21

10.2 Connect the carrier to the silo .............. 21

10. Connect conveying hoses .................... 21

11 Laying conveyor lines .................... 22

12 Connections .................................... 23

13 Opening the silo discharge flap

valve ............................................... 23

14 Hazardous dusts ............................. 24

15 Switching on and putting into

operation ........................................ 24

16 Switching off ................................... 25

1 Stopping in case of emergency ..... 26

18 Faults ............................................... 26

18.1 Safety ................................................... 27

19 Fault display .................................... 29

19.1 The following installation indicates

faults: ................................................. 29

19.2 Table of faults ...................................... 29

20 Work on troubleshooting ............... 31

20.1 Removal of clogging in hoses .............. 1

20.2 Opening the shut-off flap valve ............ 1

20. Relieving the pressure ......................... 2

20.4 Check the motor protection switch ....... 2

20.5 Restart the system after a blockage .... 2

21 Action in case of power cut ........... 32

21.1 Establishing a de-energised state ........

22 End of work ..................................... 33

22.1 End of work or interruption of work ......

23 Remove the carrier ......................... 34

2 .1 Empty the carrier .................................. 4

24 Cleaning ........................................... 34

24.1 Cleaning the conveying system ........... 4

25 Maintenance .................................... 35

25.1 Safety ................................................... 5