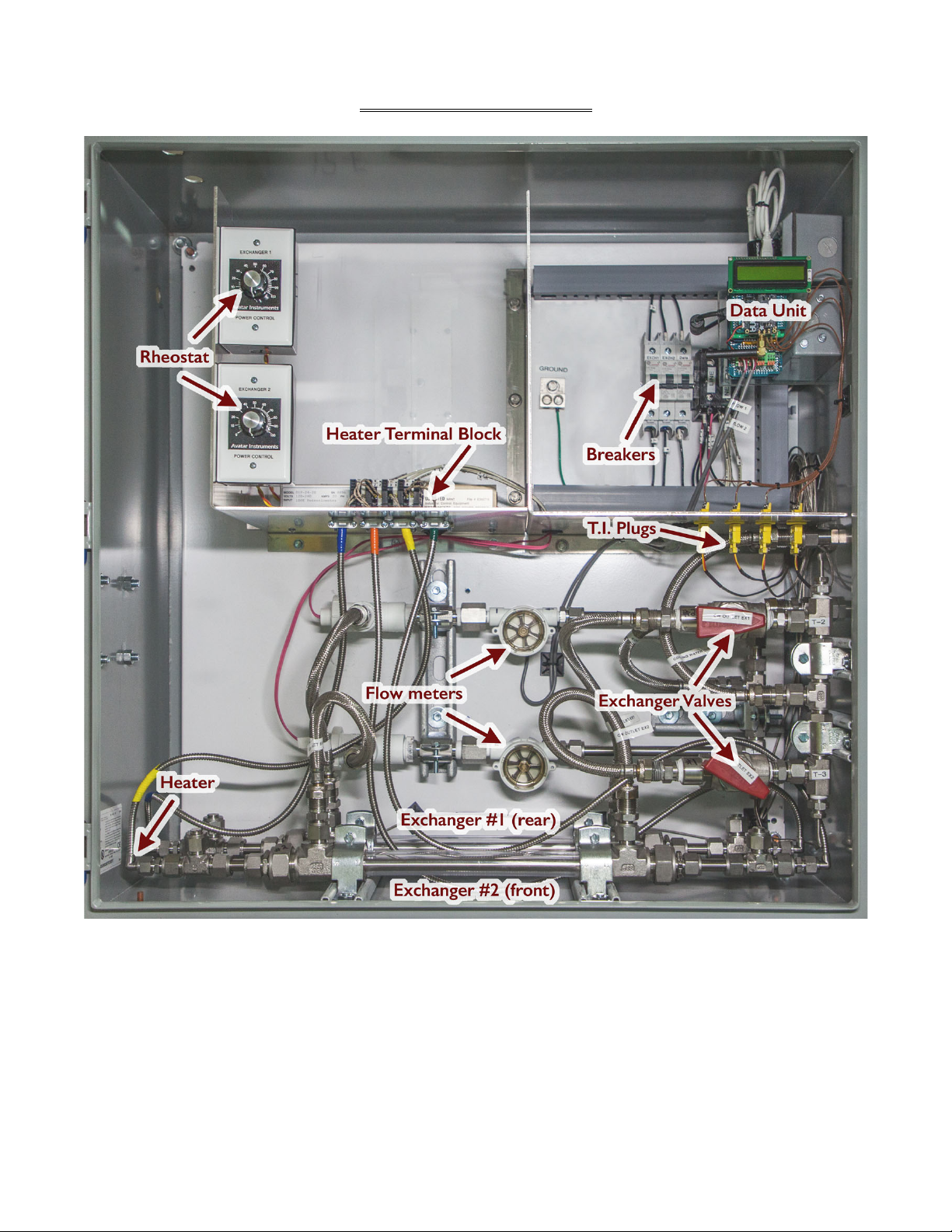

Ongoing Maintenance & Best Practices

Sentinel does not require little ongoing maintenance once the exposure period has been started. That

does not mean that you should set it and forget it.

As a best practice, we would recommend reviewing the current visible results through the clear

polycarbonate shell, at a minimum, once per week. It is also important to check that your velocity and

skin temperature settings are still correctly targeted. External climate and plant operations affect both

the supply stream pressure and cooling water inlet temperature.

It is also recommended as a best practice to periodically test the relay safety shutoff by temporarily

turning off cooling water, one exchanger at a time. When the data unit breaker is on, a green power

light on the relay board may be visible depending on how the safety relay is installed in your specific

unit. In regular operating conditions, you will see two red lights, next to the 1st and 2nd relays,

indicating that power is flowing through the relay, and everything is operational. This represents

exchanger #1 and exchanger #2 respectively. If one or both red lights are off, it is likely that cooling

water flow has been lost to a respective exchanger. If flow has not stopped, then the flow has dipped

below 0.5gpm.

Exposure period lengths are up to the operator; however, we recommend no more than 90 days per

exposure period to have an ongoing log for continuity. Following the completion of an exposure

period the tubes can be replaced and submitted for evaluation.

There is typically very little routine maintenance of Sentinel after start-up and during the exposure

period. The following are some points to consider:

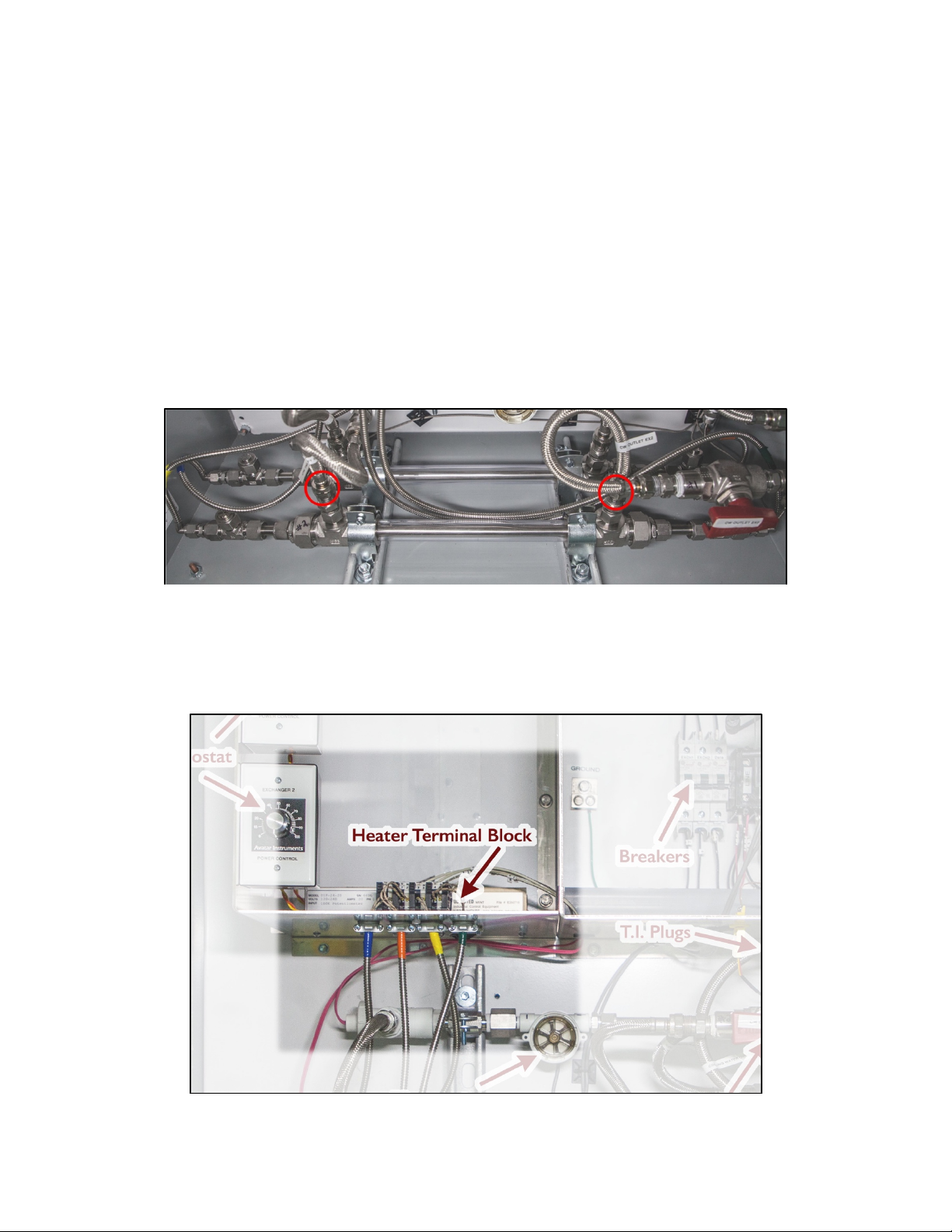

• Check the skid at least once per week for any noticeable leaks and tighten fittings as needed. If

water is lost from the process chamber during a run, turn off the heaters in that exchanger,

allow the process chamber to cool down by observing the inlet and outlet cooling water

temperature. When they are equal, it is cool. Then remove the caps and refill the chamber.

This will prevent hot spots on the ½” tube specimen.

• Check the operation of the skid at least once per week to ensure correct operation as well as

observing cooling water result.

• Photographs of the exchangers will help document the results during an exposure period and

also assist in technical support, if needed.

• If an inlet strainer is installed on the cooling water, check to ensure it is kept clean and cooling

water flow through Sentinel is not lost. Loss of cooling water flow will create non-typical

conditions for the cooling water and likely invalidate the exposure period.

• Any failure of components in Sentinel (heaters, flow meter, thermocouples, data logger, circuit

breakers or power supply) will be replaced in kind. No repair of these components is

suggested. Contact Knew Value and we will send you replacement parts as soon as possible.