© GBC Films Group April 2000

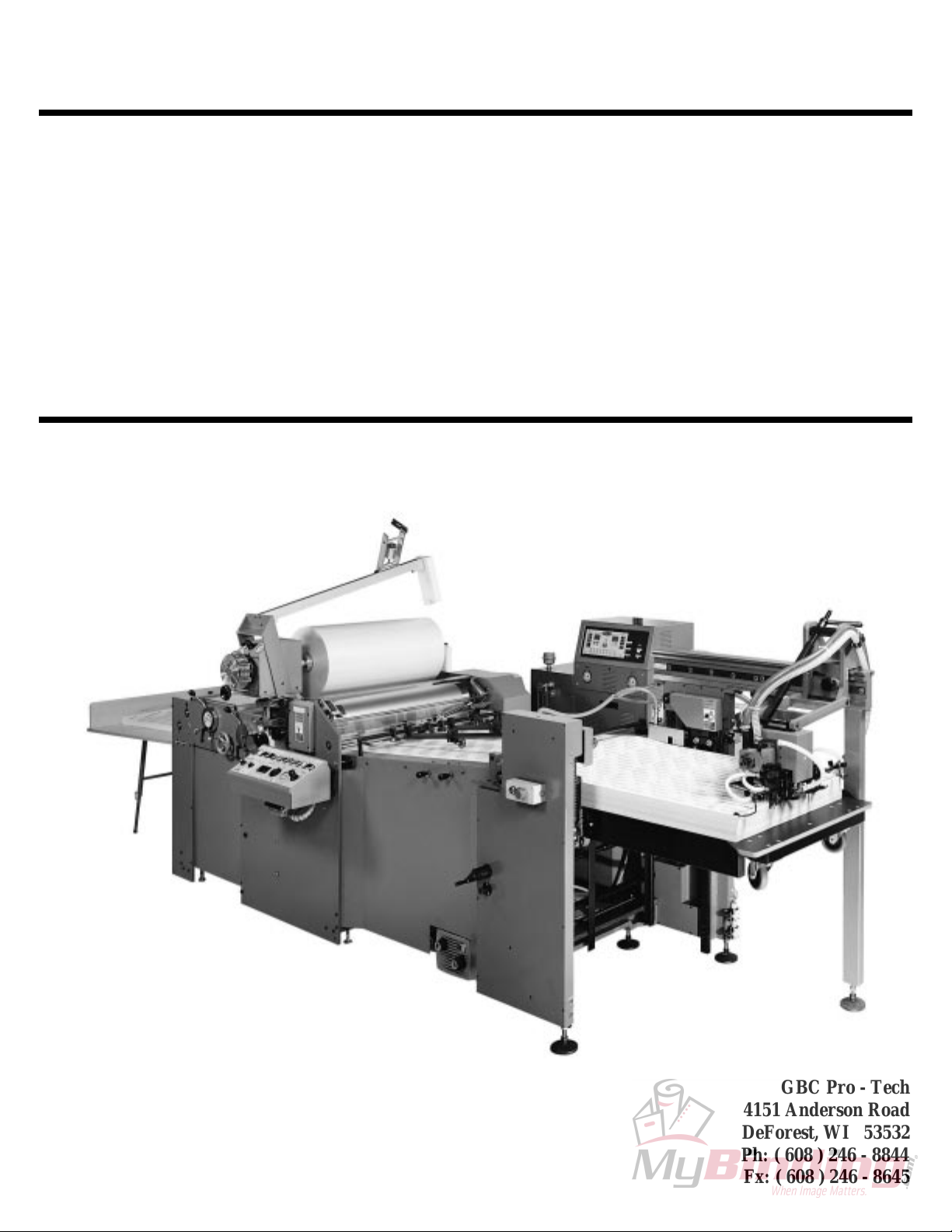

Voyager Operation and Maintenance Manual

Page 1 - 7

Warranty

1.3 Warranty

GBCFilms Groupwarrants theequipment sold

is free from defects in material and workmanship for a

period of one( 1 ) year parts ( excludes wear items )

and 90 days labor from the date of installation. This

warrantyistheonlywarrantymadebyGBCFilmsGroup

andcannot bemodified oramended.

GBC Films Group’s sole and exclusive

liability and the customer’s sole and exclusive

remedyunder thiswarrantyshall be,atGBC Films

Group’s option, to repair or replace any such

defectivepartorproduct.Theseremediesareonly

availableifGBC Films Group’s examination ofthe

productdisclosestoGBCFilmsGroup’ssatisfaction

thatsuch defects actuallyexistand werenotcaused

bymisuse,neglect, attempt torepair, unauthorized

alterationormodification,incorrectlinevoltage,fire,

accident,flood,orother hazard.

1.3.1 Limited Warranty

Thiswarrantyspecificallydoesnotcoverdamage

tothe laminatingrollers causedby knives,razor blades,

other sharp objects, failure caused by adhesives or

improper use of the machine. Warranty repair or

replacement does not extend the warranty beyond the

initialoneyearperiod fromthedateof delivery.

CAUTION

Unauthorized customer alterations will

void this warranty.

THE WARRANTY MADE HEREIN IS IN

LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING

ANY WARRANTY OR

MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. GBC

PRO-TECH WILL NOT BE LIABLE

FOR PROPERTY DAMAGE OR

PERSONAL INJURY ( UNLESS

PRIMARILY CAUSED BY ITS

NEGLIGENCE ), LOSS OF PROFIT OR

OTHER INCIDENTAL OR

CONSEQUENTIAL DAMAGES

ARISING OUT OF THE USE OR

INABILITY TO USE THE EQUIPMENT.

1.3.2 Exclusions to the

Warranty

This warranty specifically does not

cover;

1. Damagetothelaminatingrollscausedby knives,razor

blades, other sharp objects or failure caused by

adhesives.