PM - HTR - C

AutomationActuatorDivision

Wadsworth, Ohio 44281

April 1, 1994

Rev. August 1999

HTR Series Actuators

Maintenance Instructions & Parts List

Provide Model Number and Serial Number When Ordering Spare Parts.

GENERAL

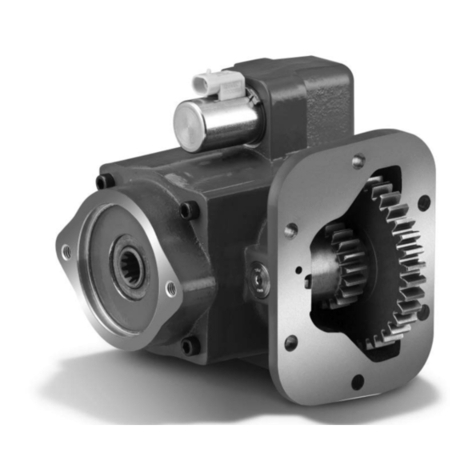

HTR Series Hydraulic Rack & Pinion Actuators are designed

for a maximum operating pressure of 3,000 psi non-shock.

The actuator consists of a Pinion and one or two Racks

located within a Housing. Pressurization of alternate cylinder

port(s) results in shaft rotation.

ThegearchamberhasbeenfilledwithaMolygreasecontain-

ing a minimum Molybdenum Disulfide (MSO2) content of 3%.

In the event that maintenance is required, the following steps

should be used as a guide:

ASSEMBLY AND DISASSEMBLY PROCEDURES

A. Inspection & Replacement of End Cap Seals, #9.

1. Place actuator in the mid-stroke position as shown.

Remove Tie Rod Nuts, #10, from Tie Rods, #13.

2. Pull End Cap, #11, free from Cylinder Tube , #12.

3. Inspect and/or replace End Cap O-Ring, #9.

Lubricate Seal and End Cap before reinstalling.

4. Replace End Cap, #11, on Cylinder Tube, #12, and

assemble Tie Rod Nuts, #10 to Tie Rods, #13.

5. Torque Tie Rod Nuts per table.

B. Inspection & Replacement of Wear Rings, #4, Piston

Seals, #5, and Cylinder O-Ring, #8.

1. Repeat Steps A1 and A2.

For Models HTR75 through HTR 600:

2. Remove Rack Bolt, #7.

3. Screw two (2) threaded rods into the tapped holes

in Piston, #16, and pull free from Cylinder Tube, #12.

For Models HTR.9 through HTR45:

4. Pull Cylinder Tube, #12, free from Housing, #2.

5. Remove Rack Bolt, #7.

For All Models

6. Inspect Piston, #16, and replace Piston Seal, #5.

7. Inspect and/or replace Wear Rings, #4.

8. Inspect and/or replace Cylinder O-Ring, #8.

9. Replace Cylinder Tube, #12 to Housing, #2.

10. Slide Piston, #16, with Piston Seal and Wear Rings

assembled onto it, into Cylinder Tube, #12, until it

contacts Rack, #17.

11.Replace Rack Bolt, #7 and torque per table.

Caution: NylonSlug,#6,isdesignedtoprevent Rack

Bolt from vibrating loose during operation; replace as

required.

12.ReplaceEndCap,#11,and Tie Rod Nuts,#10;torque

per table.

C. Inspection and Replacement of Pinion and Bearing

Retainer O-Rings, #1 and #24.

1. Loosen Lock Screw, #19.

Caution: Failure to do so will damage threads.

2. Using spanner wrench, remove Bearing Retainer,

#25, by turning counter-clockwise.

3. Remove Bearings, #22, and Pinion, #23.

Caution: Make match marks to re-establish the

correct timing.

4. Inspect and/or replace Pinion O-Ring, #1, located at

the "front" or blind side of Housing #2.

5. Reinstall Bearings, #22, and Pinion #23.

6. Inspect and/or replace Bearing Retainer O-Ring,

#24, located on outside diameter of Bearing Retainer,

#25.

7. Inspect and/or replace Pinion O-Ring, #1, located on

inside diameter of Bearing Retainer, #25.

8. Apply Moly Grease to Bearing Retainer Threads and

reinstall into Housing, #2.

9. Torque Bearing Retainer, #25 per table.

10.Install and tighten Locking Screw, #19, per torque

table.

D. Complete Disassembly of Actuator.

1. Repeat Steps A1 and A2.

2. Repeat Steps B2 through B5.

3. Repeat Steps C1 and C3.

4. Caution: Make match marks to re-establish the

correct timing.

5. Push Rack from either end to remove from housing.

E. Reassembly of Actuator.

1. Follow previous procedures for reassembly of all

actuator parts. Refill the gear chamber with Moly

Grease with a minimum MSO2content of 3%; such

as Texaco Molytex EP2.