PP

PP

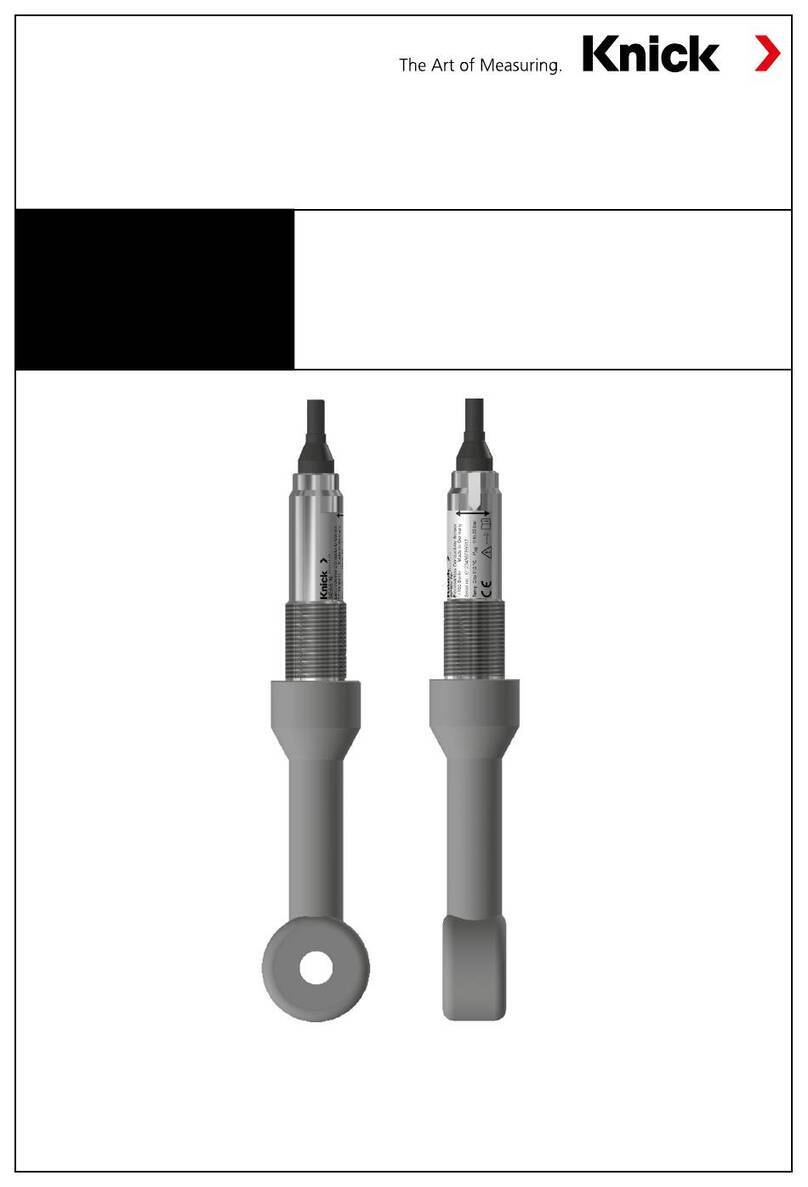

Position electrode

this side up

max. level

D-14163 Berlin

BVS 09 ATEX E 088 X

II 1G Ex ia IIC T3/T4/T6

0044

SE 557X/*-NMSH

pH 0 to 14, -1 to 6 bar, 0 to 135 °C

Position elec trode

this side up

max. level

T

V 15 AT EX 164143

Made in Germany

0044

II 1 G Exia IIC T3/T4/T6

14163 Berlin

SE 557X/1-NVPN

p -1 to6 bar C°001ot02-pmeT0 to 14

pH rel

SE557Manual

4.2 Pressurizing the Fitting

When operating the sensor, it is important that the fit-

ting and electrolyte pressure is adjusted to be higher

than the effective pressure in the reactor vessel. This

reduces the risk of process fluid getting into the sen-

sor. The optimal pressure difference value to keep the

junctions clean and obtain acceptable electrolyte re-

fill intervals has to be established empirically from

case to case, however it should be at least 0.5bar. Reg-

ularly check the applied fitting overpressure during

operation, and re-adjust if required.

5 Maintenance

Regularly check the electrolyte level in the sensor.

At the latest when reaching the end of the reservoir,

refill with electrolyte up to the indication line for max.

level.

When the sensor is not in operation, store it with sen-

sor tip and junction well submerged in electrolyte

(ZU 0958) and protected from leaking electrolyte by

the sealing plug(4) . If a sensor is stored dry for a few

days by mistake, let it soak in electrolyte for several

hours before use.

6 Accessories

Memosens Ex cable CA/MS-010XAA

(Example: 10 m)

Electrolyte ZU0958

7 Specifications

The model designation, which is printed on each

sensor and on the packaging label, includes the

following information:

SE 557X/1-NMSN Model designation (example)

Sensor material

N: Alpha glass

Sensor connector

MS: Memosens

Solution ground

N: without

Length

1: 120 mm

2: 250 mm

Ex approval

X: Yes

pH range 0 ... 14

Temperature -20 ... 100 °C

Temp detector NTC 30 kΩ

Pressure, relative -1 ... 6 bar

Reference system Ag/AgCl

Electrolyte KCl, 3 mol/l,

for low temperature application

Junction Ceramic (2x)

pH glass Alpha glass, medium imped-

ance, fluoride resistant

Length 120 mm / 250 mm

Installation in Knick fittings for pressurized

sensors

8 Disposal

Observe the applicable local or national regulations

for disposal.

Instructions for Use for the SE 557 pH Sensors

WARNING – Failure to observe this warning may

result in serious injury.

The safety alert symbol on the nameplate means:

Read these instructions for use, observe the

specifications, and follow the safety instructions.

1 Safety Instructions

1.1 All Applications

Hazards due to pressure, temperature, aggressive me-

dia, or explosive atmosphere are possible, depend-

ing on the location of use. Therefore, the installation,

operation, and servicing of the sensor shall only be

carried out by suitably trained personnel authorized

by the operating company.

1.2 Hazardous Areas

Observe the corresponding local requirements and

standards for electrical installations in hazardous

areas. For orientation, please refer to IEC 60079-14,

EU directives 2014/34/EU and 1999/92/EC (ATEX),

NFPA 70 (NEC), ANSI/ISA-RP12.06.01.

Memosens Ex sensors are marked by an

orange-red ring. The Memosens Ex sensors

shall only be connected to a cable of type

CA/MS-***X** or to an intrinsically safe and certified

Memosens measuring cable which is identical in

hardware and function.

2 Intended Use

The sensor is designed for operation in a Knick fitting

and is used for continuous measurement of pH values

in liquid media.

3 Installation and Commissioning

•On unpacking, check the sensor for mechanical

damage. Report any damage to your Knick

service team.

•Remove the watering cap. Rinse the sensor with

clean water. Only dab the sensor to dry it.

Note: Do not rub the pH-sensitive glass, since

this can lead to electrostatic charging and slug-

gish response times.

•Remove any air bubbles behind the pH-sensitive

glass by gently swinging the sensor.

•Remove the protective foil from the electrolyte

filling hole (3). Fully remove the sealing plug(4)

prior to installation in the fitting.

NOTICE! The sensor may break if installed in the

fitting with the sealing plug.

Keep the sealing plug(4) for future use.

Note: If the sensor is stored outside the fitting,

the sealing plug(4) serves to protect it from

leaking electrolyte.

•Insert the sensor into the grounded fitting.

Refer to the user manual for the fitting.

Note: Suitable fittings can be found at

www.knick-international.com.

•Connect sensor and cable.

4 Operation

4.1 Calibrating the Sensor

2-point pH calibration is recommended for the SE 557

sensor. First remove the watering cap. Then dip the

sensor successively into two different buffer solutions

with given pH values (e.g., pH 7.00 and pH 4.00) and

calibrate the pH transmitter to these buffer values.

Memosens sensors can be adjusted using the calibra-

tion data. Please refer to the user manual of the pH

transmitter for further details.

1

Ø 12 mm

6

Knick

Elektronische Messgeräte

GmbH & Co. KG

Beuckestraße 22

14163 Berlin

Germany

Phone: +49 30 80191-0

Fax: +49 30 80191-200

www.knick-international.com

TA-SE557-TIIS-KNEN07 20200914

1Sensor connector:

Memosens

2Serial number

3Filling hole

4Sealing plug

5Maximum filling height

6Nameplate

120 / 250 mm

2

5

Remove the protective

foil prior to use.

Fully remove the

sealing plug(4) prior

to installation in the

fitting and keep it for

future use.

4

3

MEMO SENS