Page 6 of 12 0901177 Rev: A (10/15)

OPERATION

Detergent — Probe Mode

The system has the option of using a conductive. With

the detergent signal “on”, the probe senses detergent

concentration. When concentration drops below the

setpoint, the control automatically turns on detergent

feed. As the detergent feeds, the control senses the rate

at which the detergent concentration is approaching the

setpoint. The control then begins to pulse feeds to

prevent over-use of chemical. The pulse feed rate will

depend on how fast the setpoint is being approached.

The detergent alarm will sound if the setpoint is not

reached within the alarm delay time period. The alarm

can be temporarily silenced. A “feed limit” feature allows

you to set the unit to automatically shut off the detergent

feed when the alarm has been activated.

Detergent — Probeless Mode

Controls detergent concentration without a probe, based

on timed detergent feed modes. Initial charge time feeds

detergent to bring the dishmachine to working

concentration when initially filled with water. The initial

charge can be activated by a detergent signal, or by the

rinse signal (of 30 seconds duration, or longer) when

using door mode. The initial charge counter will

increment for each activation.

Recharge time feeds detergent to maintain detergent

concentration as rinse water dilutes the dishmachine.

The recharge is triggered after a specified number of

racks passes through the machine.

Rinse Pump

The rinse pump will operate whenever the rinse signal is

energized. The rinse delay feature will postpone the

activation of the rinse pump until the delay time has

expired. The rinse limit shuts down the rinse pump after

the signal has been present for a selected time. Rinse

delay and rinse limit are functional with door machines

only.

BUTTON FUNCTIONS

ENTER: Holding the enter button for 3 seconds

(approx.) switches between run and program modes.

Enter also advances through programming menus.

SCROLL: The scroll button moves the position of the

cursor where number changes are done. The scroll

button toggles between choices in menus that have

selectable settings.

UP (): Increases numeric values during

programming The UP button also acts as rinse prime

during operation. To prime the rinse pump, hold down

SCROLL and UP at the same time. The UP button

also shows the rack count if pressed during operation.

DOWN (): Decreases numeric values during

programming. The DOWN button also shows the

initial charge count if pressed during operation (only

when using probeless mode).

TO PRIME DETERGENT: To prime detergent (pump

or solenoid) hold down the UP and DOWN buttons at

the same time.

TO PRIME RINSE: To prime rinse pump hold down

the SCROLL and UP buttons at the same time.

Alarm Mute

During normal operation, the low detergent alarm

(probe mode) can be silenced by pressing the ENTER

button. The audio alarm will turn off for the alarm delay

period of time to allow the chemical container to be

checked and changed if necessary.

De-Lime Mode

Press ENTER and SCROLL until de-lime mode shows

on the display. Chemical injection will be halted while de

-lime mode is on but will resume normal operation when

turned off. The unit will automatically exit de-lime mode

after 10 minutes, or pressing ENTER and SCROLL.

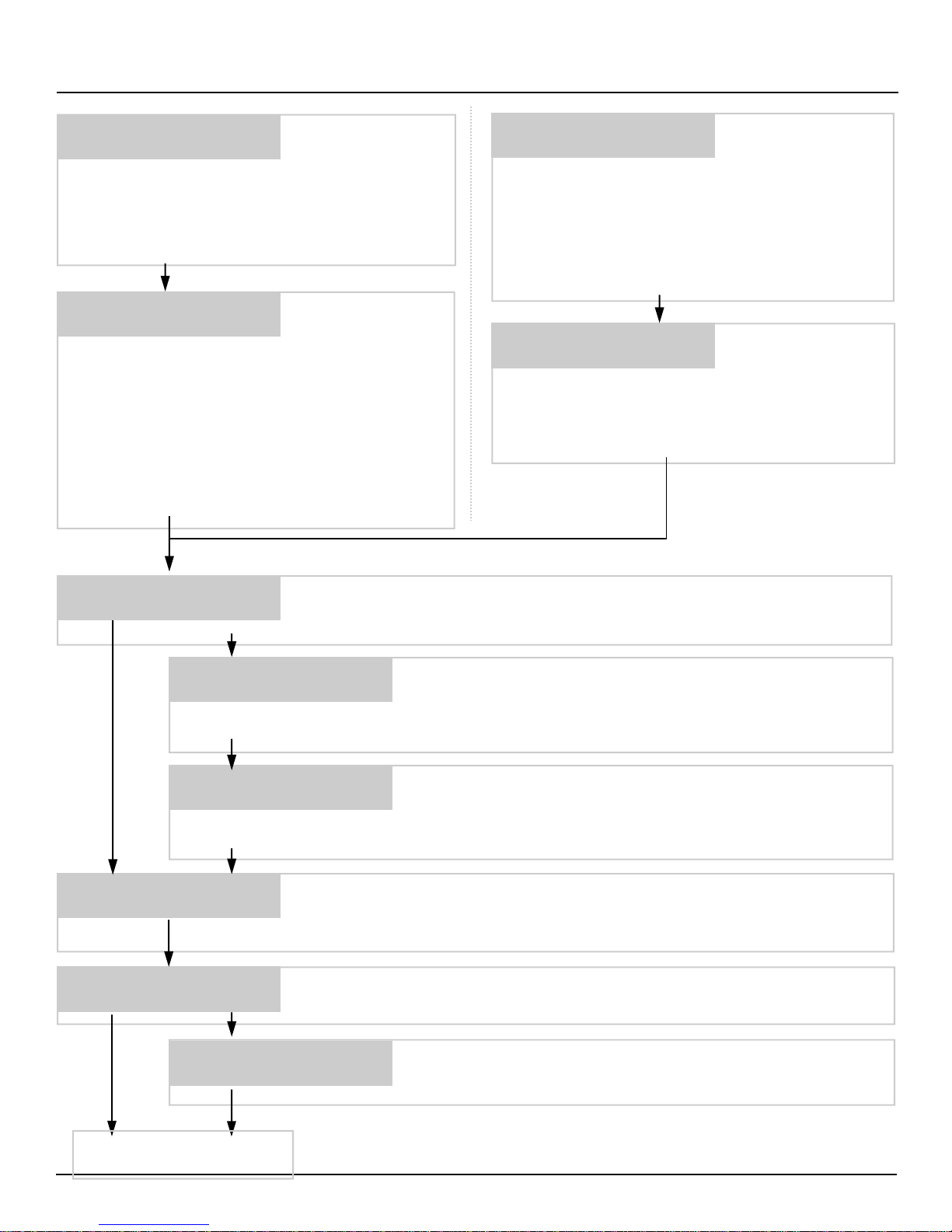

PROGRAMMING

If you wish to exit the programming mode, or save

new settings, and return to normal operation at any

time, hold down the ENTER button until you see the

UMP DIGITAL display return (about 3 seconds).

While programming, if no buttons are pressed for

approximately 2 minutes, the UMP Digital will

automatically return to normal operating mode.

Changes will not be saved.

To change the value of any numeric setting, press

SCROLL to select the digit you wish to change, then

use /to change the number. The digit will flash to

show you which one is selected.

When you’re ready to get started, hold down the ENTER

button until you see ENTER PASS CODE (about 3

seconds) then continue on the following page...

OPERATION