4 5

KOBE

INDUSTRIAL

AIR TOOLS

KOBE

INDUSTRIAL

TOOLS

ASSEMBLY & INSTALLATION

Fig. 3

Fig. 4

KOBE

INDUSTRIAL

TOOLS

OPERATION

KOBE

INDUSTRIAL

TOOLS

ASSEMBLY & INSTALLATION

The Hose Reel can be mounted to either a wall or ceiling. Ensure the wall, ceiling or other structure, to

which the Hose Reel is to be attached to, is of sound construction and the securing points and fixings will

hold the the working strain exerted onto the Hose Reel when in use. Remember that the Hose Reel will be

heavier when it is used to transfer water.

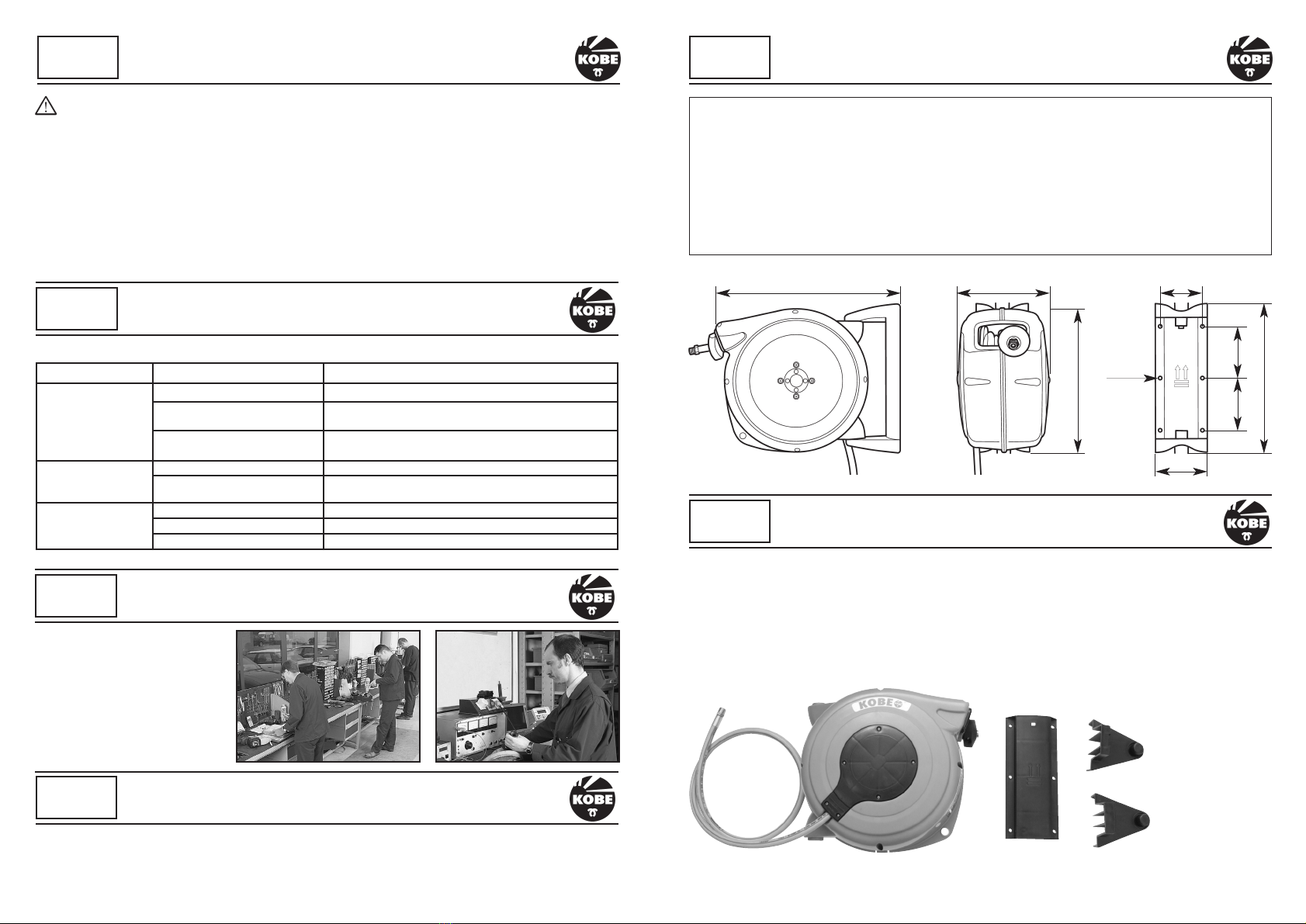

1. If wall mounting,

position the Hose

Reel so that the hose is

pulled out no more than

15°in an upward or

downward direction

(See fig. 1). Exceeding

this can create undue

drag in operation and

potentially cause

premature wear to the

mouth opening of the

Hose Reel.

2. Place the bracket body

against the wall/ceiling and mark and drill appropriate holes.

3. Position the lower bracket arm onto the bottom of the bracket body

(See fig. 2).

4. Screw into position making sure that the arrows on the bracket

body are facing upwards if the Hose Reel is being mounted on a

wall (See fig. 3). It is important that all six screw holes are used.

5. Mount the Hose Reel onto the lower bracket arm.

6. Slide the upper bracket arm onto the Hose Reel making sure that

clip “A” fully engages into hole “B” (See fig. 4).

Fig. 1

Fig. 2

Fig. 5

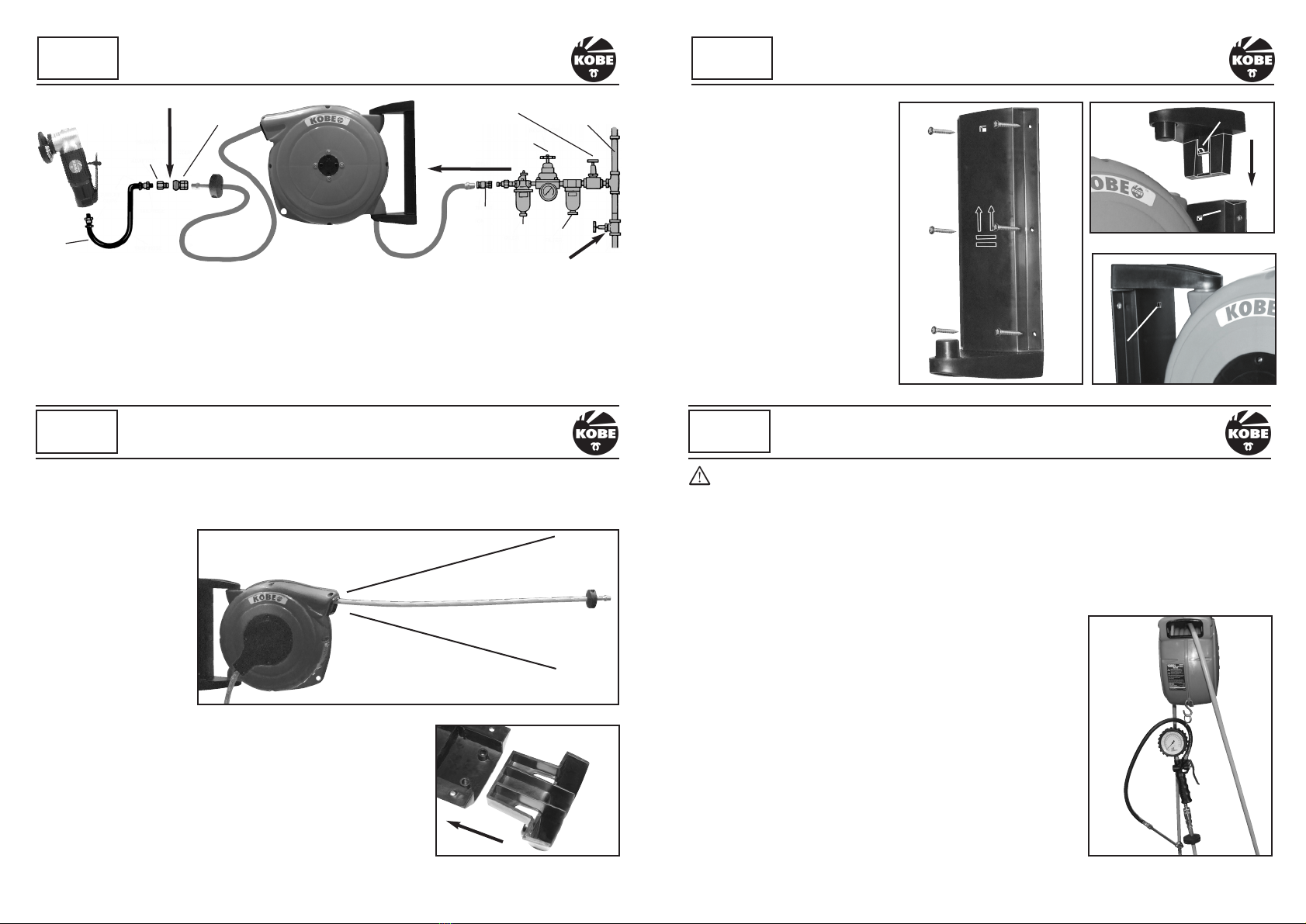

Always keep a firm hold of the hose as it is retracting back into the reel. Never allow the hose to

fly back uncontrolled as this could cause damage to property, yourself or other people.

In order to familiarise yourself with the function of the Hose Reel, stand as close as possible to it and

follow the steps below:

EXTENDING OUT AND LOCKING

1. Pull the hose slowly out and you will hear a clicking noise. This is the locking pawl running over the

locking teeth.

2. As soon as you hear the clicking noise, stop pulling and allow the hose to retract a little and it will lock

in position.

3. If it will not lock, allow the hose to retract back further, then pull it out again slowly until you hear the

first one or two clicks. Stop pulling and allow the hose to retract a

small amount and it will lock in position.

4. Now pull it out some more until you hear the next set of clicks and

repeat the locking process. The hose will lock about every 1 metre

(3 feet). The hose can be pulled all the way out until it stops.

Once you are familiar with the system, you will not need to listen for the

locking clicks as you will automatically know when and where it locks.

RETRACTING

1. Pull the hose out a little until you hear the clicking stop. The ratchet

pawl will make a “clunk” noise.

2. As soon as you hear the “clunk” sound allow the hose to retract

back whilst holding it firmly.

3. If you want to stop the hose rewinding and lock into position again,

pull some hose out until you here clicking. Allow it to retract a little

so that the hose locks into position.

The hole at the bottom of the Hose Reel can be used to hang air tools

or water spray guns (See fig. 6). Air tools which can not be held like this

should be removed. The “S” hook is not supplied with the Hose Reel.

KOBE

INDUSTRIAL

TOOLS

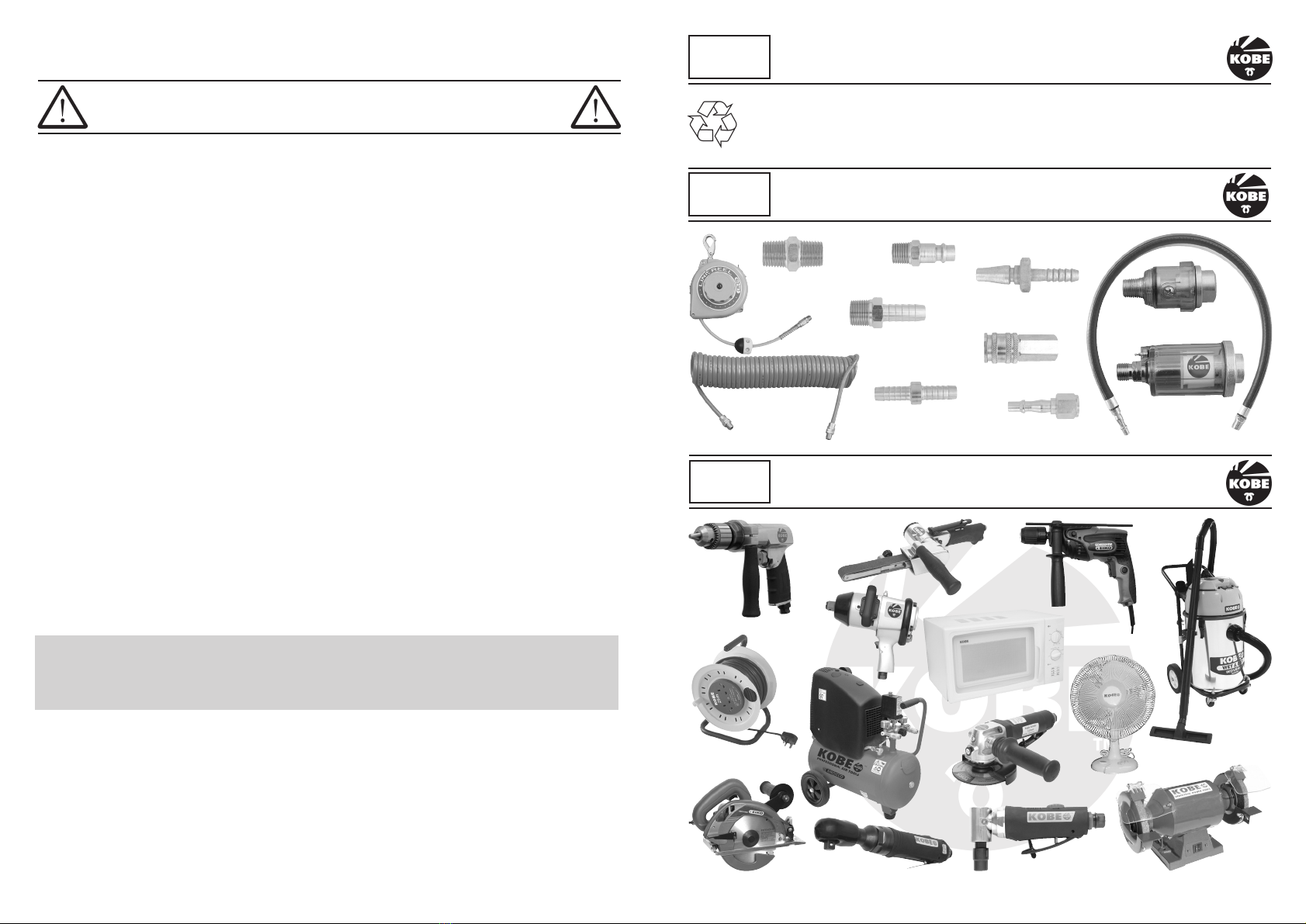

SUGGESTED AIR SUPPLY

ADAPTOR

OILER

STOP VALVE PIPES AND

FITTINGS

REGULATOR

COUPLING

OIL DAILY HERE

COUPLING

WHIP

HOSE

FILTER

DRAIN DAILY

AIR SUPPLY

Always ensure that if a hose is used between the air supply and the Hose Reel, the pressure rating of

the hose is equal to or greater than the pressure rating of the Hose Reel.

Always use thread sealants where applicable and permitted.

Never over-tighten or under-tighten fittings.

Requirements for Quick Acting Couplings connected to Air Tools:

A whip hose of minimum length 500mm between the tool and the coupling is required in order to comply

with Health and Safety Executive Guide HS(G) 39, BS4575:2, ISO 4414 and ISO 6150.

7. Connect the inlet of the Hose

Reel with the air/water supply.

Make sure the outlet has a

connection on it before switching

on slowly the air/water supply

to check for leaks.

REMOVAL

The hose must be fully retracted

before the Hose Reel is removed from

the bracket body (See below for how

to retract the Hose Reel).

Place a screwdriver into hole “B” and

push in clip “A”. At the same time

pull the upper bracket arm out a few

millimeters keeping the Hose Reel

pivoting. Whilst holding onto the Hose

Reel between your arm and body, pull

the upper bracket arm fully out (See

fig. 5).

Fig. 6

15°

15°

A

B

B

Continued

Continued on page 5