Kodak i800 Series User manual

Other Kodak Scanner manuals

Kodak

Kodak Mini Digital Film Scanner User manual

Kodak

Kodak i5000 Series User manual

Kodak

Kodak i100 Series User manual

Kodak

Kodak Scanmate i920 User manual

Kodak

Kodak ScanMate i940 User manual

Kodak

Kodak i5800 Scanner User manual

Kodak

Kodak i5800 Scanner User manual

Kodak

Kodak i2400 User manual

Kodak

Kodak i1220 Plus User manual

Kodak

Kodak Ngenuity 9150 User manual

Kodak

Kodak 2400 DV Plus User manual

Kodak

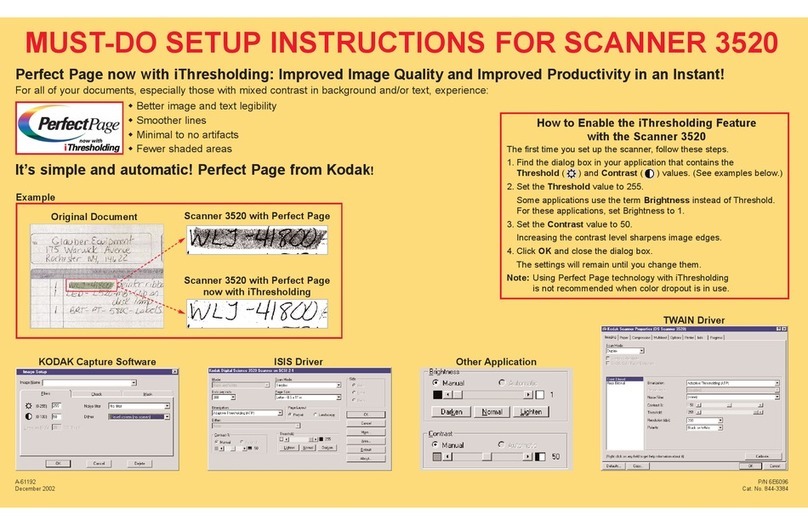

Kodak 3520D - Digital Science Manual

Kodak

Kodak Ngenuity 9000 Series User manual

Kodak

Kodak Mobile Film Scanner User manual

Kodak

Kodak A3 User manual

Kodak

Kodak i4250 User manual

Kodak

Kodak Ngenuity 9090DB Operating instructions

Kodak

Kodak INNOVATION I100 User manual

Kodak

Kodak HR User manual

Kodak

Kodak I1420 - Document Scanner User manual