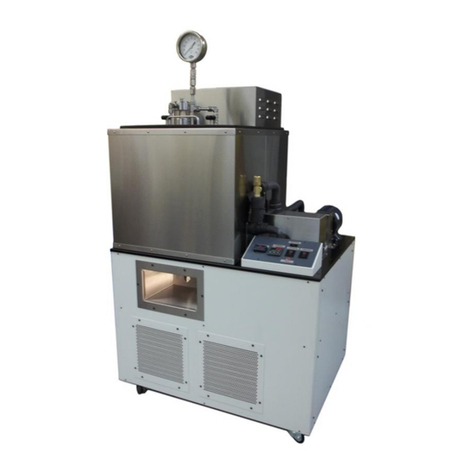

ADA5000 Automatic Distillation Analyzer

Operation and Instruction Manual

ADA5000-Manual - 3 -

Ice Formation. Selecting low temperatures in

the receiver chamber with level follower system

for distillation groups 0,1,2,3 may produce ice on

the pipes of the air-heat exchanger system. Ice

could decrease the efficiency of cooling and

could effect damages to the exchanger. In case

of ice, it is absolutely necessary to thaw out the

pipes.

3 Unpacking & Installation

The instruction for preparing this equipment

assumes that the user is aware of the contents

of this document, which lists the warranty

conditions and important precautions.

3.1 Packing List

Please refer to the shipping documents for the

Automatic Distillation Analyzer regarding items

included on the packing list.

3.2 Unpacking

Carefully unpack and place the instrument and

accessories in a secure location. Ensure that all

parts listed in the previous section are present.

Inspect the unit and all accessories for damage.

If you find any damage, keep all packing

materials and immediately report the damage to

the carrier. We will assist you with your claim, if

requested. When submitting a claim for shipping

damage, request that the carrier inspect the

shipping container and equipment. Do not return

goods to Koehler without written authorization.

3.3 Instrument Installation

Equipment Placement: Unit must be set on a

firm and stable bench capable of supporting at

least 250 lbs. It is advisable to place the unit in a

location with sufficient ventilation, preferably an

exhaust hood. Locate the unit in a non-corrosive

atmosphere. Room temperature must be below

86°F.

Electrical: Determine the electrical

requirements of the model distillation unit to be

installed. Measure the voltage supply for the

unit’s location and determine if it is correct.

Requirements for the different models are:

K45603, K45703-TS: 120VAC +/- 5%

50/60Hz, 20A

K45604, K45704-TS: 230VAC +/- 5%

50/60Hz, 10A

Nitrogen: Nitrogen must be available in order

for the automatic fire extinguishing system to

work. Connect a ¼” line capable of withstanding

100psi to the valve located in the top/back of the

unit. Adjust the line pressure to 70psi.

PC: If an external PC is to be used, locate within

50 ft of the first distillation unit to be connected

(See figure below). Connect to the unit by

RS232 cable. If PC does not have a COM Port

available, use a USB to Serial adapter cable.

Connect cable from the PC to the 25 pin PC

Adapter Plug that connects to the 25 pin

connector at the distillation unit. This adapter

MUST be installed for communications to work.

If multiple units are being installed, the units

must have a RS232 cable connected in daisy

chain to each unit in series.

Set/verify the address of the unit if multiple units

are to be installed. See section in Descriptions

for setting Unit Address.

Connect printer and proceed to install software.

3.4 Software Installation

If the distillation software is not pre-installed,

then insert the CD-ROM into the CD tray of the

PC. The CD should automatically display the

setup screen. If this does not happen within 10

seconds, then browse the files on the CD-ROM

and double click on the setup file (setup.exe) to

start the installation. Follow the instructions on

the screen to setup the software. The setup

program will require the PC to be restarted at

the end of the installation. Please close any

open programs before installing. The next

several pages will guide you through the

software installation process. Once the

installation has been completed, then you are

ready to run the software.

Note that on the K457XX-TS models, the

software is preloaded and the touch screen has

been calibrated at the factory. If you need to

recalibrate the screen, the calibration utility can

be accessed by clicking on Start >> All

Programs >> Fujitsu Touch Panel >> Touch

Screen Calibration Utility, as shown in Figure