- 26 -

Introduction

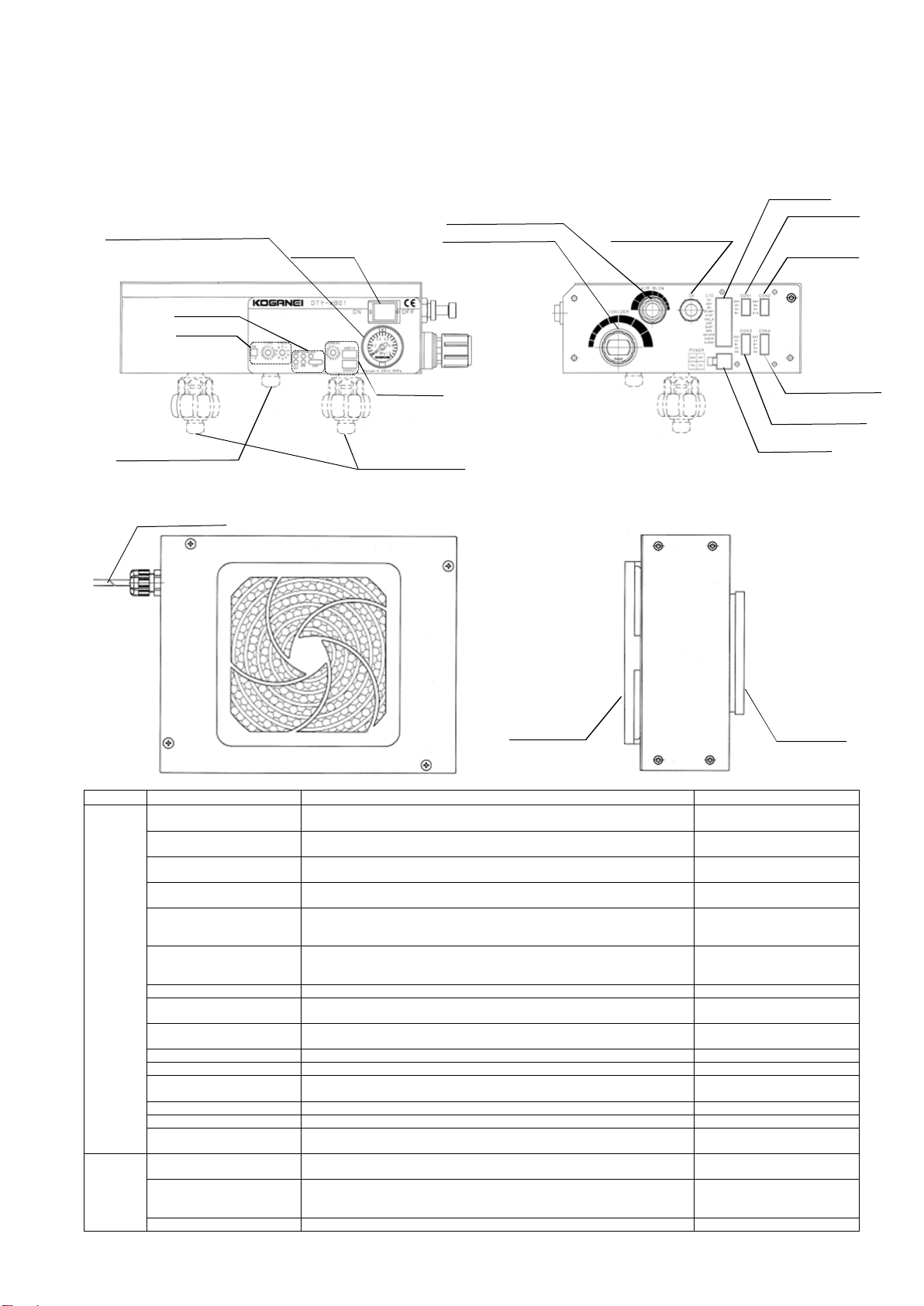

Thank you for purchasing "ION WIPER, Separate Type".

Although this device is not subject for the standards for electric installation as a high voltage apparatus,

this device uses 2000 V AC voltage. Please read this Operating Instructions manual and the Operating

Instructions of Ionizer Air blow Type [DTY-ELK01] for appropriate handling and operation of this device.

Please keep this manual for your reference and consult it as needed.

1. Safety Precaution

Warning

This device is not for explosion-proof or water-proof. Do not install this device in a location where combustible

gases and/or solvents are used (in a coating booth, for example). Otherwise, there is a risk of ignition and/or

explosion.

When cleaning the discharge needle, always turn off the device. Also, the tip of the discharge needle is sharp, pay

attention when handling the discharge needle. Otherwise, there is a risk of injury.

This device uses the input air. When turning on this device, always input the air.

As high voltage is applied to the discharge needle equipped to the ionizer, do not move the fingers, body, and

metal pieces such as wires and tools close to the discharge needle. Otherwise, it can lead to an electric shock or

device failure. This device is a high voltage equipment. Do not install this device in a place exposed to water or oil,

high temperature, or high humidity. Especially, avoid a place with high humidity and a chance of dew

condensation.

The fluid used for the ionizer is the air. Do not use any other fluid.

Never disassemble, repair, or modify this device. Otherwise, it can lead to an accident or device failure.

Always turn off the device before performing the wiring, installation, and inspection tasks. Otherwise, it can lead to

an accident, electric shock, or device failure.

Do not point the nozzle tip to a person.

Wear the protective glasses and ear plugs to prevent scattering objects by the air blow from entering eyes and

noise induced deafness.

Install a shut-off valve on the supply side to ensure safety in case of a leak or breakdown.

Caution

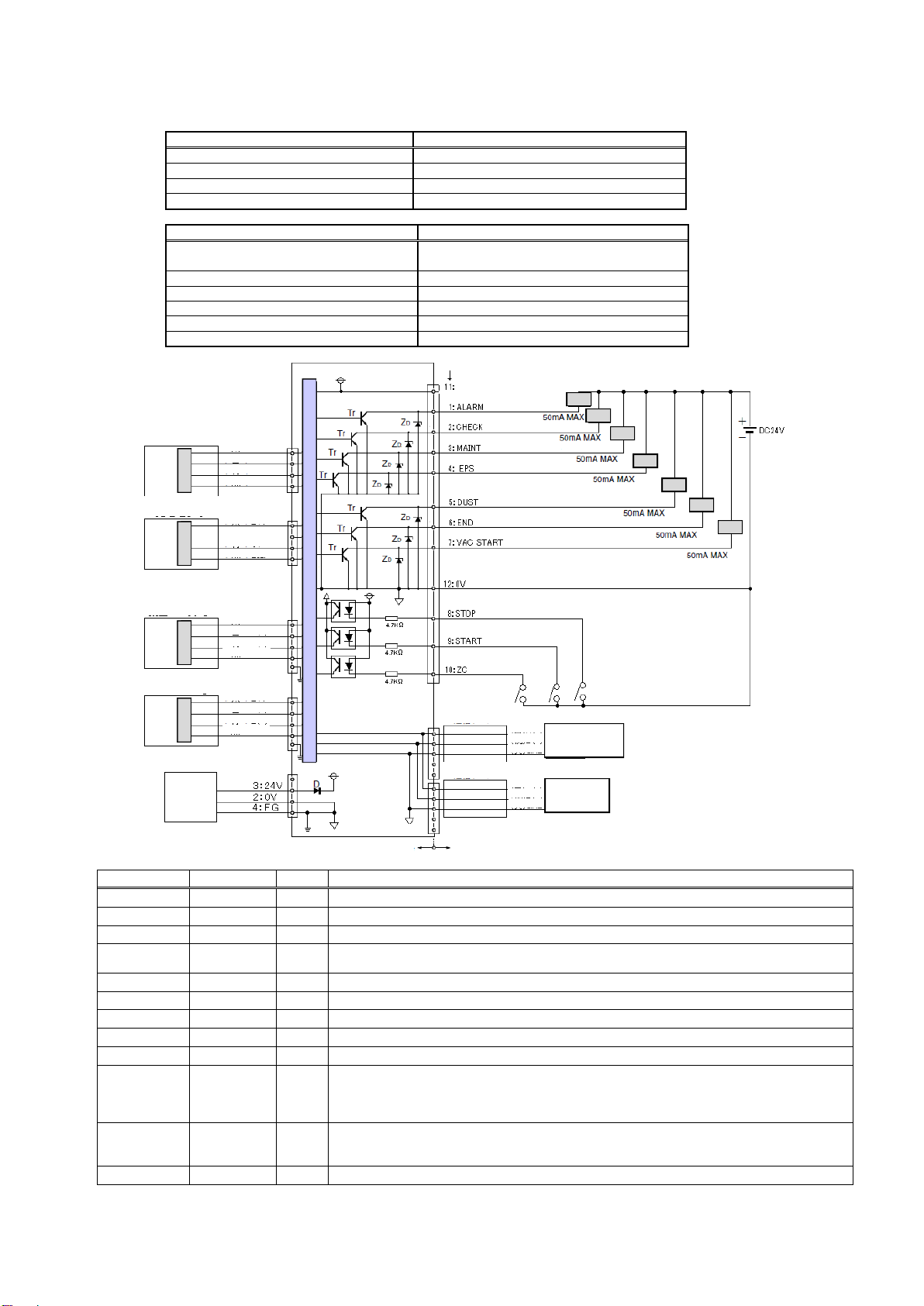

Always ground the wire. Otherwise, it can lead to poor static charge removal characteristic or failure.

When this product is unusable or no longer necessary, the product should be disposed of as a piece of industrial

waste.

For the worker to be able to cut the power immediately, install a switch or a circuit breaker and label it properly.

Please wire properly. Incorrect or inappropriate wiring can cause a functional failure.

For the DC power source, use output voltage DC 24 V with double or reinforced insulation.

Due to the EN specification, wiring should be within 30 m.

This device has a high voltage generator. Do not cause abnormal discharge by moving a metal piece to the

discharge needle while current is applied. Otherwise, it can lead to failure or damages of peripherals or this

device.

The ionizer generates ozone in the air. Ventilate the room when the ozone odor is felt.

Do not move your face closer to the ion outlet to check the ozone odor. Otherwise, there is a risk to damage the

nose and throat.

This product cannot be used if the following substances are included in the fluid used :

Organic solvent, phosphate hydraulic operating fluid, sulfurous acid gas, chlorine gas, acids.

Do not use this device in a location exposed to direct sunlight (ultra-violet ray); with dust, salt, or iron powder; high

humidity; or atmosphere with organic solvent, phosphate hydraulic operating fluid, sulfurous acid gas, chlorine

gas, or acids. Otherwise, it can lead to loss of function in short period, rapid decrease in performance or shorter

life span.

The life of the discharge needle varies depending on the operating environment. A poor operating environment

(atmosphere with high humidity, for example) and/or unclean discharge needle can degrade the performance. A

periodical maintenance is required.

Please be advised that inrush current would be applied when turning on this product and when the built-in DC fan

in the dust collecting unit starts.

Air contaminated with oil and/or solid matters cannot be used. For the supplied fluid, use the cleaned air (use a

filter with a nominal filtration rating of 40 μm or less). Drain or dust entered inside the product can cause an

operational failure.

To prevent dew condensation and freeze due to the blow from the product, maintain a dew-point temperature of

the supplied fluid lower than the ambient atmosphere temperature using a refrigeration air dryer and/or an after

cooler.

Do not drop, step on, or hit the product. Otherwise, the product may be damaged.

Walls or objects near the exhaust slot of the dust collecting unit affects the exhaust ventilation. Please keep

enough spaces when installing the product.

For other warning and caution items, refer to the “Safety Precautions” in the general catalog.