1. Safety information------------------------------------------------------------------------------------------ 1

2. Safety precautions----------------------------------------------------------------------------------------- 2

3. Location of Safety labels --------------------------------------------------------------------------------- 7

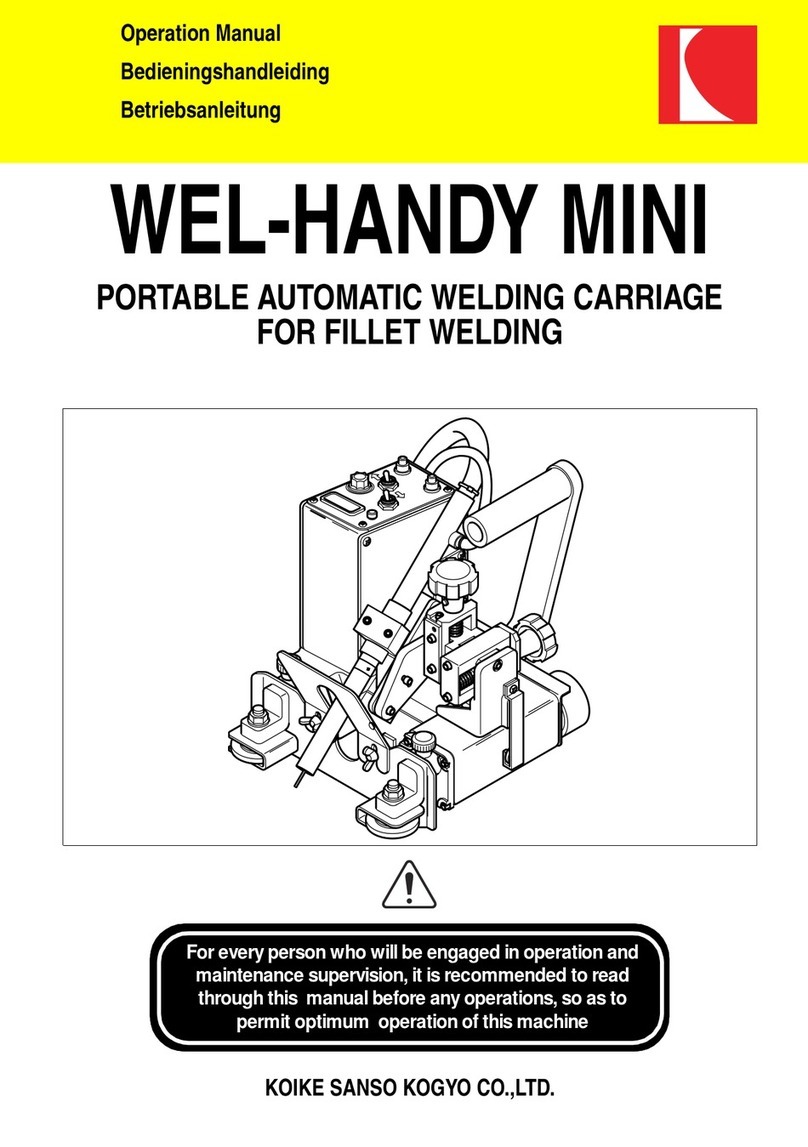

4. Features and specifications ----------------------------------------------------------------------------- 8

4.1 Features ----------------------------------------------------------------------------------------------8

4.2 Configuration ----------------------------------------------------------------------------------------8

4.3 Specification -----------------------------------------------------------------------------------------9

5. Method of operation------------------------------------------------------------------------------------- 10

5.1 Name of each part---------------------------------------------------------------------------------11

5.1.1 Main unit of welding carriage -----------------------------------------------------------11

5.1.2 Operation panel--------------------------------------------------------------------------- 16

5.2 Preparation and procedure for welding------------------------------------------------------ 18

5.3 System connection diagram-------------------------------------------------------------------- 19

5.4 Applicable welding machine and signal adaptor ------------------------------------------ 19

5.5 Operational precautions ----------------------------------------------------------------------- 19

6. Maintenance ---------------------------------------------------------------------------------------------- 20

6.1 Maintenance and inspection ------------------------------------------------------------------- 20

6.1.1 Daily inspection--------------------------------------------------------------------------- 20

6.1.2 Monthly inspection ----------------------------------------------------------------------- 21

6.2 Recommended spare parts -------------------------------------------------------------------- 21

6.3 Trouble shooting---------------------------------------------------------------------------------- 21

6.4 Warranty-------------------------------------------------------------------------------------------- 23

7. Wiring diagram-------------------------------------------------------------------------------------------- 24

7.1 Electrical diagram--------------------------------------------------------------------------------- 24

7.2 Assembly drawing of circuit board ------------------------------------------------------------ 25

8. Assembly drawing of WEL-HANDY COMPACT -------------------------------------------------- 26

9. Parts list---------------------------------------------------------------------------------------------------- 27

9.1 Main body and inside parts--------------------------------------------------------------------- 27

9.2 Holder relationship ------------------------------------------------------------------------------- 29

9.3 Arm relationship----------------------------------------------------------------------------------- 31

9.4 Electrical parts(1) -------------------------------------------------------------------------------------

33

9.5 Electrical parts(1) --------------------------------------------------------------------------------- 35

10.About the use of commercial torches-------------------------------------------------------------- 36