AKI-CDA-MOD-07T|SAFETYPRECAUTIONS

2 SAFETYPRECAUTIONS

Boththeinstallerandtheownerand/oroperatoroftheoperatorpanelmustreadandunderstand

thisinstallationmanual.

2.1 General

• Readthesafetyprecautionscarefully.

• Checkthedeliveryfortransportationdamage. Ifdamageisfound,notifythesupplierassoonas

possible.

• Donotusetheoperatorpanelinanenvironmentwithhighexplosivehazards.

• Thesupplierisnotresponsibleformodified,alteredorreconstructedequipment.

• Useonlypartsandaccessoriesmanufacturedaccordingtospecificationsofthesupplier.

• Readtheinstallationandoperatinginstructionscarefullybeforeinstalling,usingorrepairingthe

operatorpanel.

• Neverallowfluids,metalfilingsorwiringdebristoenteranyopeningsintheoperatorpanel. This

maycausefireorelectricalshock.

•Onlyqualifiedpersonnelmayoperatetheoperatorpanel.

• Storingtheoperatorpanelwherethetemperatureislower/higherthanrecommendedinthis

manualcancausetheLCDdisplayliquidtocongeal/becomeisotopic.

• TheLCDdisplayliquidcontainsapowerfulirritant. Incaseofskincontact,washimmediately

withplentyofwater. Incaseofeyecontact,holdtheeyeopen,flushwithplentyofwaterandget

medicalattention.

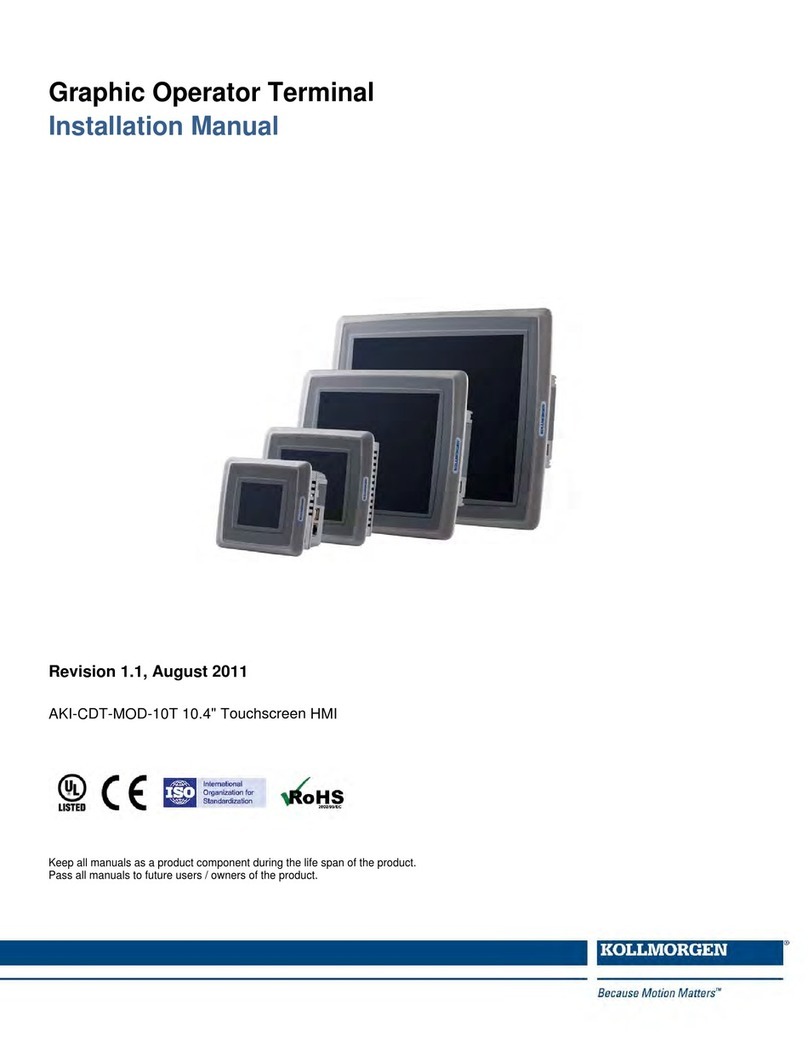

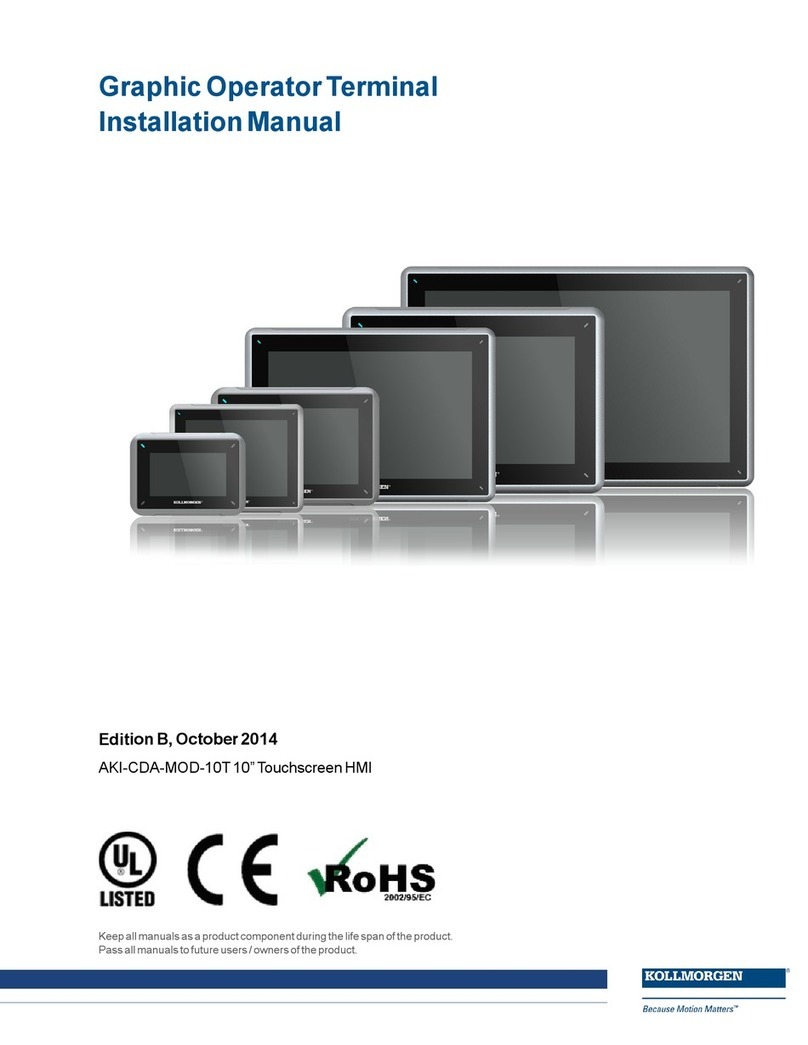

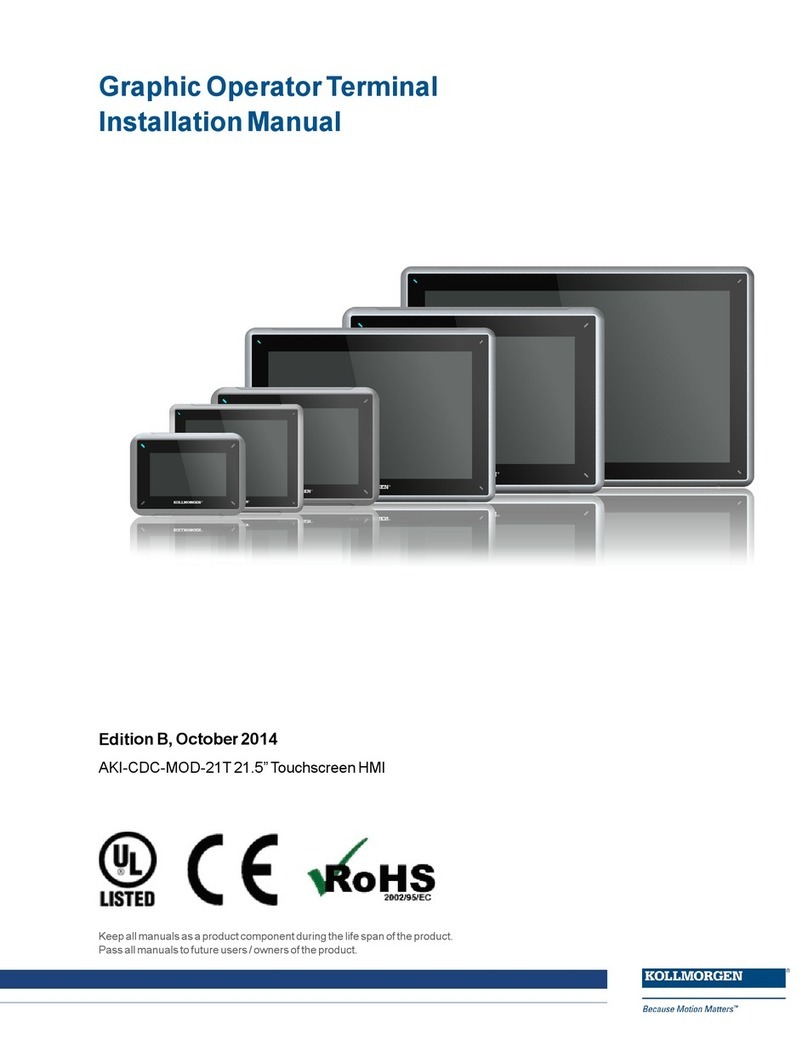

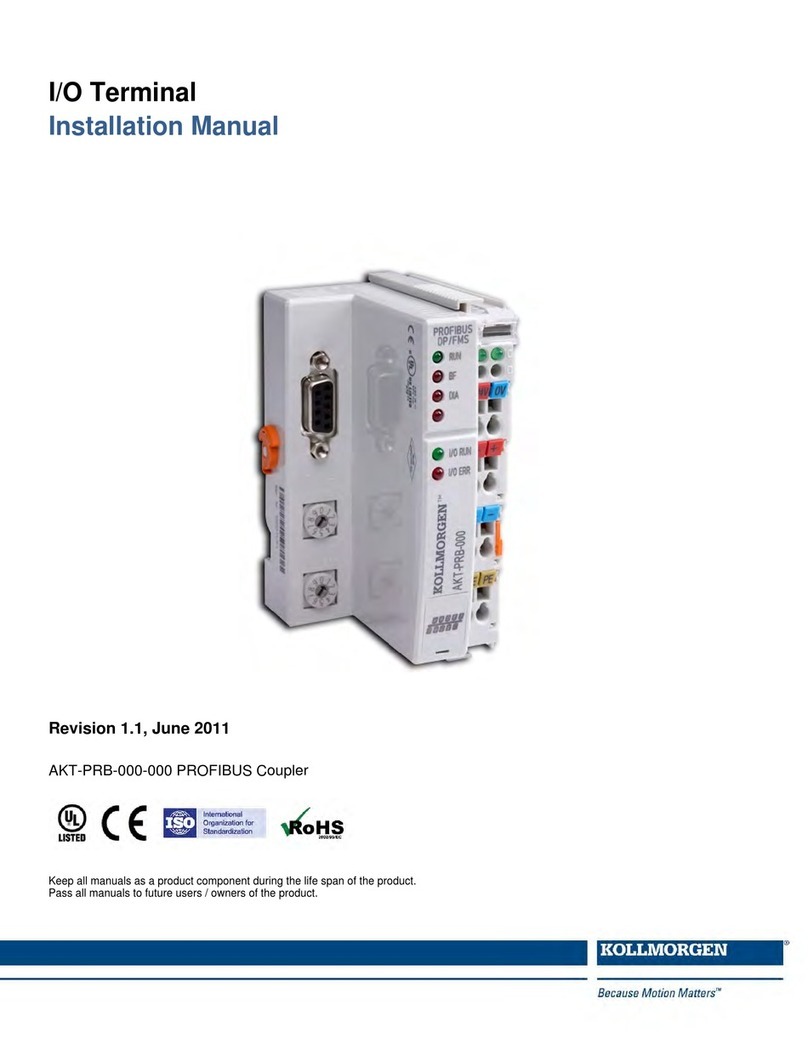

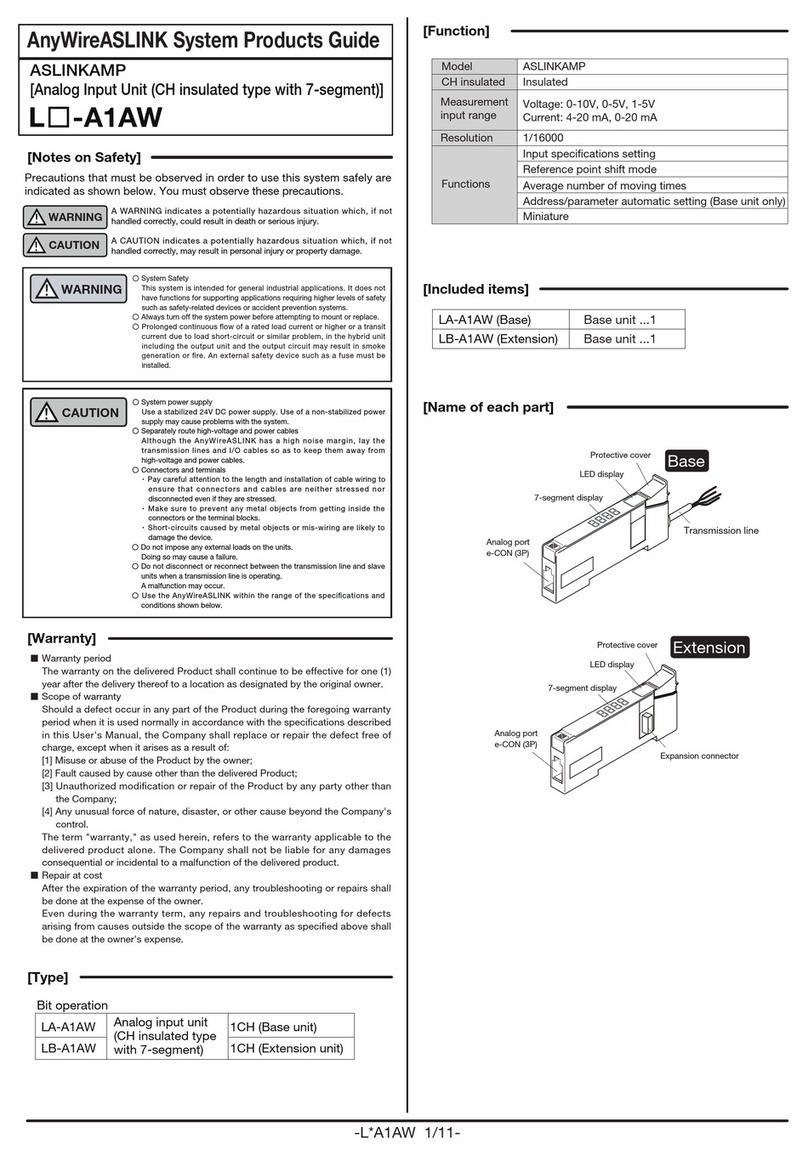

•Thefiguresinthismanualservesanillustrativepurpose. Becauseofthemanyvariables

associatedwithanyparticularinstallation,thesuppliercannotassumeresponsibilityforactual

usebasedonthefigures.

• Thesupplierneitherguaranteesthattheoperatorpanelissuitableforyourparticularapplication,

norassumesresponsibilityforyourproductdesign,installationoroperation.

• Itisrecommendedtoturnonandshutdowntheoperatorpanelatleastoncebeforeinstallingany

components/cardsorbeforeconnectingtheoperatorpaneltoexternaldevices,likeforexample

serialdevices.

2.2 ULandcULInstallation

•Thise

quipmentissuitableforuseinClass2non-hazardouslocationsonly. [Combinationsof

equipmentinyoursystemaresubjecttoinvestigationbythelocalauthorityhavingjurisdiction

atthetimeofinstallation].

•Alld

eviceshavetobesuppliedbyaClass2powersupply.

Donotdisconnectequipmentunlesspowerhasbeenremovedortheareaisknownto

benon-hazardous

ky Kollmorgen|July2013 5